How to Select Easy Peeling Films for Medical Packaging Applications | EVER POLYMER

Throughout this article, we will be exploring the most important factors when selecting the right easy peel film material and design.

How to Select Your Best Fit Easy Peel Films?

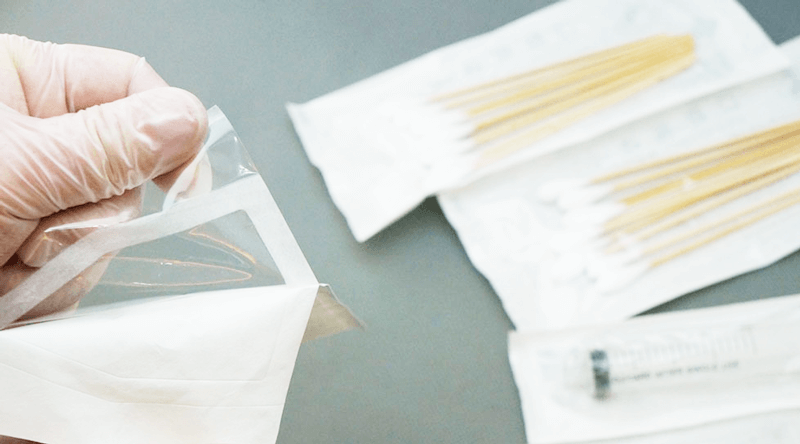

Deciding what desired seal and peel properties for your packaging can be one of the critical decisions you will need to make. As a medical-grade TPE material expert and manufacturer for Easy Peel films, Everlon outlines below the top 5 things to be considered.

- Capability to be used for various types of medical device packaging :

The major materials for medical device packaging include medical-grade paper (or an alternative to medical-grade paper like Tyvek), aluminum, or plastic (such are LLDPE, PP, PET, HIPS, and vinyl). Having a supplier who can offer you flexible material solutions for Easy Peel Films is important, so that you will not have a problem matching materials to various device packaging requirements. It will save you time, effort, and cost during the development stages.

- Materials that leave no lingering residue:

Medical packaging must be formed and sealed accurately and consistently. Meeting the requirements for strength, the bond of the seal after heat-sealing, the visual aesthetics of the seal, and the ability to easily open the packaging, are all critical characteristics which must be met. If the user has problems opening a medical device packaging, the packaging may rip or tear exposing and contaminating the contents which may lead to possible failure of the components. A qualified medical-grade TPE is key to achieving high-quality Easy-to-Peel films with no lingering no residue.

- Resistance to sterilization:

There are a variety of sterilization techniques commonly used in the medical industry for medical devices. Sterilization can take a toll on packaging materials. So, material compatibility is an important factor in determining which sterilization method to use. Most medical devices rely on EO and gamma radiation sterilization. Therefore, ensuring that the plastic material you select is compatible with the sterilization method will meet the sterilization cycles requirements. This will ensure that multiple sterilizations will not change the mechanical properties of your Easy Peel Films, such as tensile strength, impact strength, and elongation.

- Essential medical device cleanroom requirements:

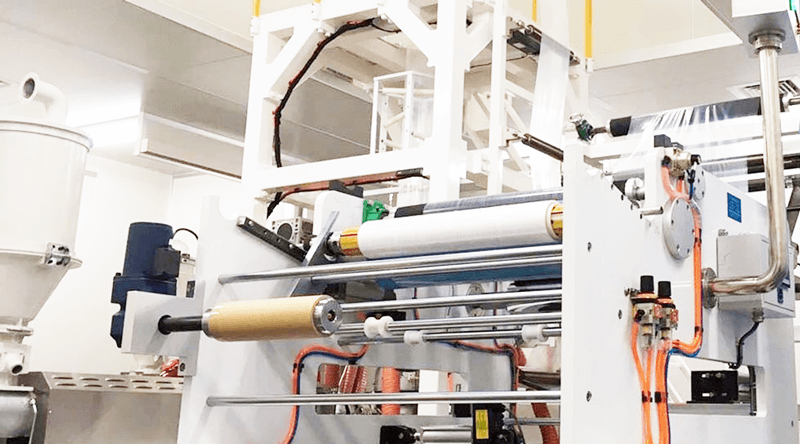

Bacteria or microorganisms can create a safety concern for patients. In order to keep medical devices free from contaminants, you or your supplier must maintain control of the packaging processes in a clean-room environment. This is to ensure that the Easy Peel Films and Easy Peel Film Materials do not contribute to contaminating the Medical devices.

- USP Class VI qualified materials:

USP outlines specific classes for plastic materials. USP Class VI is the strictest, requiring that materials exhibit very low levels of toxicity as proven through a series of tests. A plastic material that has passed class VI certification is expected to be more likely to produce favorable biocompatibility results in order to eliminate the risk of adverse reactions in patients.

Easy-to-Peel Films Material Manufacturer

In medical device packaging, a peelable film provides a controlled, reliable, aseptic means of opening a package and protecting a medical device. Using our TPE for Easy Peel Films ensures the highest quality packaging, and as a result you will get the excellent quality, strength, and consistency for your medical device packaging. Everlon offers a wide selection of Peelable Film Materials for the medical industry allowing highly customized peelable structures which can match your specific medical packaging applications !

Original Post : https://www.everlon.com.tw/en/article/easy-peel-film-for-medical-device-packaging.html

With “EVERLON” as our main brand, we specialize in the development and applications of TPE. Four major application series — EVERMedi, EVERSeal, EVERPeel and EVERAuto — have been further created according to different professional fields, with the aim to satisfy the demands for global TPE markets in terms of the top four high-end application areas, namely medical devices, food packaging, commodity sector, and automobile parts.