HUARONG Launches Optimized Two-Platen Injection Molding Machine and Composited Injection Blow Molding Machine

Huarong is a Taiwanese manufacturer of injection molding machines for more than 40 years. "Industrial alliances create value for customers " as the core spirit for Huarong, being a worthy injection molding partner for customers is what Huarong insists on. Adding value for the customer, Huarong provides integrated services from injection molding machine to automation to smart factory plan.

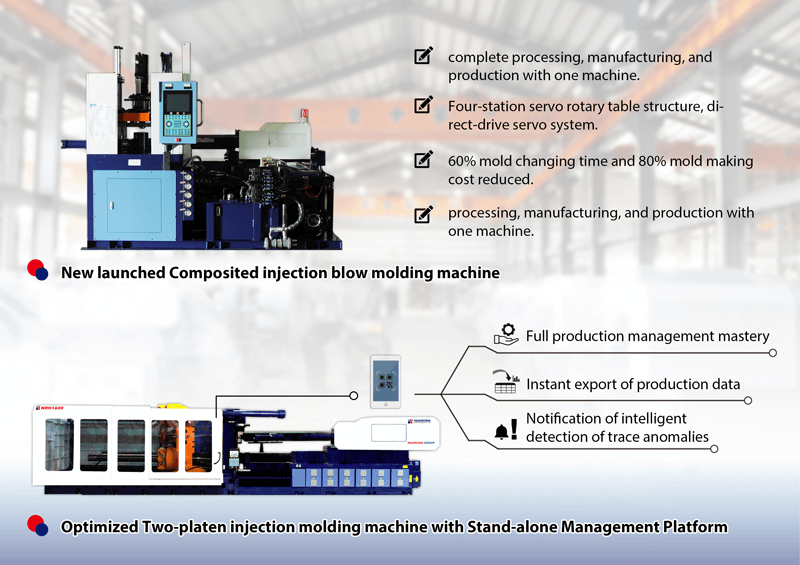

Optimized Two-Platen Injection Molding Machine with Management System

Compared with toggle injection molding machine of the same tonnage, the machine length of two-platen injection molding machine is about 15% shorter, which can improve the utilization rate of the workshop space.

HUARONG launch the optimized two-platen injection molding machine, in addition to the original advantages, the structure of the bearing support is different that the machine body will not shake

when the 4 direct-pressure hydraulic cylinders are clamped at high pressure, which reduces the probability of tie-bar breakage and saves the cost of machine maintenance.

Equipped with the latest development, stand-alone intelligent management system, the administrator can connect to the machine controller through the movable device to check the "machine status" and "production information". The management system also has the intelligent inspection function independently developed by Huarong, aiming at 7 production parameters, which can predict the machine condition in advance and eliminate it early.

Composited Injection Blow Molding Machine

Break through the possibility of vertical injection molding machine in injection production, integrate the advantages of multi-station rotary vertical injection molding machine and add the composite functions of other stations, HUARONG launch composited injection blow molding machine to meet all customer's customized design needs.

Compared with the separated injection and blow molding into two machines, this composited injection blow molding machine has a smaller size, which occupies small workshop space, and can complete in one step without secondary heating.

The advantage of the machine is able to change the mold easily. Equipped with a four-station servo rotary table structure and a direct-drive servo system, the rotary table system has a reproducibility of 99.9% up of the rotation position. It's suitable for producing various styles and small quantities of plastic products to reduce the mold change time by 60% and the mold make cost by 80%.

From Injection Molding Machine to Automation to Smart Factory Plan

Huarong Group has been focusing on injection molding technology and products for many years that taking sturdiness and smart management as the core of the product to provide customers with stable equipment. For the whole plant planning, HUARONG not only has injection molding machines, but also has HRB servo manipulator and HFM smart factory management system to assist customer to build a 24-hour unmanned smart factory.

HUARONG GROUP is based on exceptional designs & quality services. With more than 40 years experiences in manufacturing injection molding machines, HUARONG GROUP integrates “YUH-DAK MACHINERY CO LTD.” and “NAN RONG MECHANICAL CO., LTD.” to offer complete injection molding solutions for both vertical / horizontal applications with unique characteristics and strengths.

Dependable, reliable, and durable designs with ISO 9001/2015 & CE Certified.

HUARONG GROUP, based in TAIWAN, brings you the equipment for the most satisfaction. As the core value of the company is “Quality-Innovation and Appreciated by Industry Alignment” to offer the win-win solution to you.