Author : POLYSTAR Co.

Subscribe Now

POLYSTAR vs. Chinese machines -Which one has more benefits?

Chilean producer shares his experience

In Chile, POLYSTAR has become a reliable supplier. The results are especially rewarding in quality because year by year improves and increases. Also, the design of the machine is attractive and simple, and the optimization of resources has left customers 100% satisfied. POLYSTAR technology, in the extrusion and bag-making machines, increases the production and the quality of the final products.

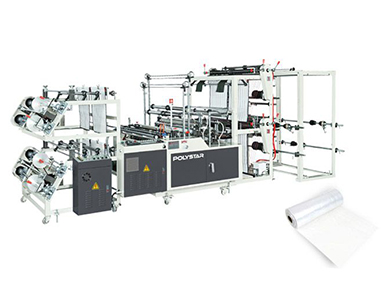

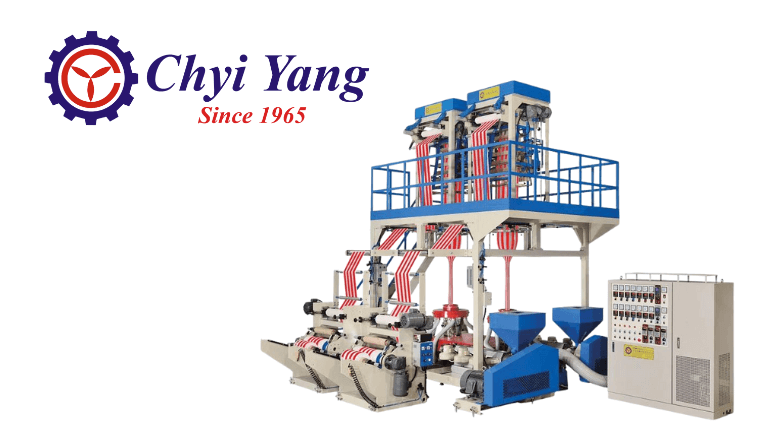

The bag manufacturer, Rodrigo Muñoz, shares his experience with Chinese and POLYSTAR machines. In 2018 he purchased his first POLYSTAR machine, a PM42. This machine produces perforated bags, specially design for Plastic Films HDPE/LDPE/LLDPE. The following year he acquires two sets of one-layer twin head blown film machine. And this year, 2021, he is waiting for his third twin head extruder.

The bag manufacturer, Rodrigo Muñoz, shares his experience with Chinese and POLYSTAR machines. In 2018 he purchased his first POLYSTAR machine, a PM42. This machine produces perforated bags, specially design for Plastic Films HDPE/LDPE/LLDPE. The following year he acquires two sets of one-layer twin head blown film machine. And this year, 2021, he is waiting for his third twin head extruder.

POLYSTAR vs. Chinese machines

At the time of purchasing a machine, several factors are taken into account, the first, and for many people the most important, it’s the cost of machinery, but this is only the slightest element because, in the long run, the cost of virgin materials, energy, space, and operational cost will be higher, if you do not have a correct guidance when seeing all the factors. This is why the full operating cost has to be considered, and the benefits of investing, initially, in a good machine will reduce the total operating costs.

Rodrigo Muñoz, general manager of Plasticos MP, said “… when we compare machines from POLYSTAR, talking about production, technology advance, final product, and the percentage increase in production versus a Chinese machine… in production, we gained more than 40% with POLYSTAR”.

The plastic film quality from POLYSTAR blown film machines, provide a reduction of inconveniences in sealing. Rodrigo said that before they had many problems in the production line, but now that changed because they found the perfect solution to their problems: POLYSTAR Machinery “… Fewer problems in the sealing… fewer losses, fewer claims among the sealing staff towards the extrusion staff…” Rodrigo said.

Rodrigo Muñoz, general manager of Plasticos MP, said “… when we compare machines from POLYSTAR, talking about production, technology advance, final product, and the percentage increase in production versus a Chinese machine… in production, we gained more than 40% with POLYSTAR”.

The plastic film quality from POLYSTAR blown film machines, provide a reduction of inconveniences in sealing. Rodrigo said that before they had many problems in the production line, but now that changed because they found the perfect solution to their problems: POLYSTAR Machinery “… Fewer problems in the sealing… fewer losses, fewer claims among the sealing staff towards the extrusion staff…” Rodrigo said.

Best service. Best quality.

POLYSTAR has always been at the forefront in machines as in customer service, assisting customers after-sales. POLYSTAR supports its customers with technicians and engineers. Rodrigo has been proof of this service “you not only introduce me to the brand but also you and POLYSTAR give me the technical support and logistic to make this work well...” he said. The benefits of working with POLYSTAR are more production and better quality.

More information of POLYSTAR:

https://www.polystarco.com/en/index.html

More information of POLYSTAR Extruders:

https://www.polystarco.com/en/products_sub_F02.html

POLYSTAR at PRM

https://www.prm-taiwan.com/com/polystar.html

More information of POLYSTAR:

https://www.polystarco.com/en/index.html

More information of POLYSTAR Extruders:

https://www.polystarco.com/en/products_sub_F02.html

POLYSTAR at PRM

https://www.prm-taiwan.com/com/polystar.html

Author:POLYSTAR Co.

Headquartered in Taiwan, POLYSTAR has focused on user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high quality pellets in a simple and easy way.

POLYSTAR linkedin: https://www.linkedin.com/company/76949389/admin/

POLYSTAR linkedin: https://www.linkedin.com/company/76949389/admin/