K Fair

HOT NEWS

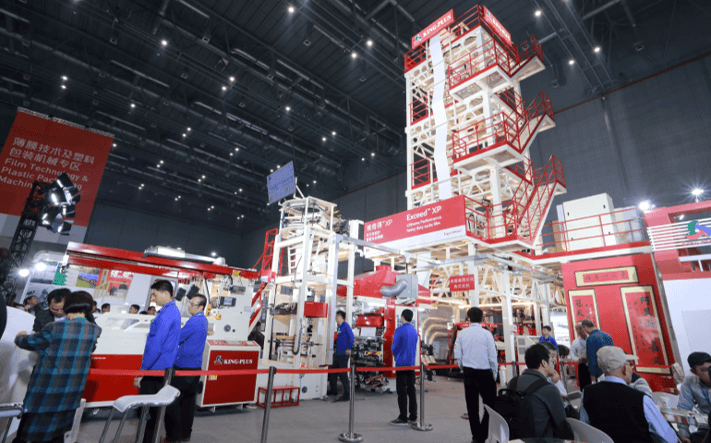

K 2022, A Total Success for the biggest Exhibition in the Plastics and Rubber Industry

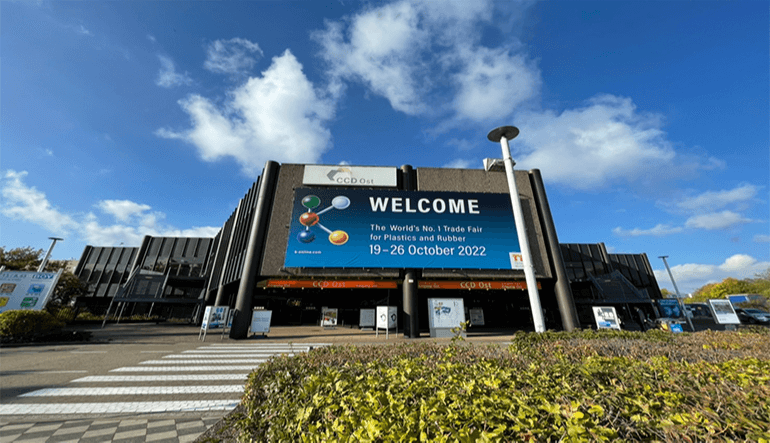

Since 2019, the Trade Fairs and Exhibitions industry didn’t hold as many exhibitions as expected due to the pandemic that affected many economic sectors due to travel restrictions. We can say that K 2022 is the first big exhibition in the plastics and rubber industry which brought over 176,000 visitors from over 157 countries, including Taiwanese companies this year over 85 exhibitors.

HSIN LONG: Leading Innovations in Multi-Layer Extrusion Dies to Achieve Sustainable Development Goals

K Trade Fair as the biggest and the most influential worldwide exhibition in the Plastics & Rubber Industry has been hotly held from 19 to 26 October. There is no doubt that everyone has already been waiting too long for this extravaganza especially after the effects of the COVID-19. HSIN LONG is no exception, bringing their newly innovated Multi-Layer Blown Film Extrusion Die...

HAN KING: Review K-2022 - Post Consumer Recycling for Environmental Resource Circulation

At K-2022, Han King displayed its five-layer heavy duty sack blown film production line comprising in-line printing machine and embossing device, via real time live streaming from their manufacturing plant. The resin formulation was supported by Borouge, with 30% post-consumer recycled resins.

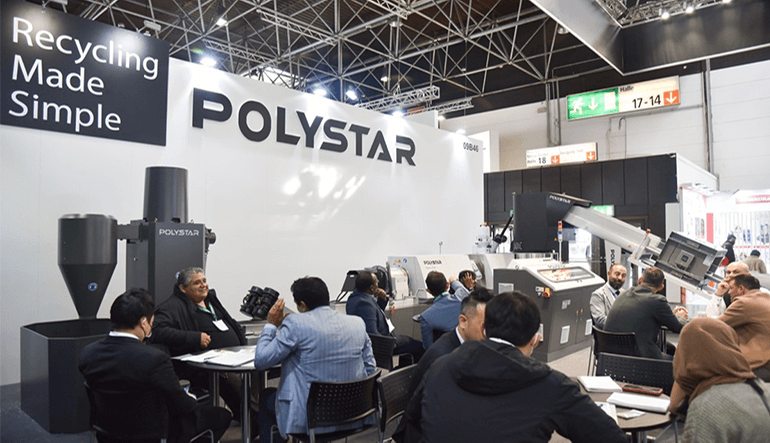

K Show 2022 -Recycling for Post-consumer and Post-industrial Plastics on the Rise

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste.

Botheven, Ready to Showcase Innovation and New Developments During K 2022

After 3 years of forth and coming due pandemic full of new challenges, the biggest exhibition in the plastics and rubber industry is just around the corner. Many manufacturers are presenting the hard work they have put into new technologies during these 3 years, always have better performance and quality options for customers around the world.

HAN KING: New High-capacity FFS Heavy Duty Packaging Film Production Machine Launch at K 2022

The trend of the petrochemical industry has a great demand for heavy-duty packaging equipment. The petrochemical industry is growing rapidly in developing countries. The extraction of petroleum produces various materials like fuel oil, fuel gas, asphalt and others. Some of them are directly use as fuel for our daily usage.

TAIWAN KINKI: All Electric Vertical Injection Molding Machine, Fits Topics of K 2022

K as one of the biggest Plastics and Rubber international exhibitions which is held every three years, kicked off from 19 to 26 October 2022. K has announced this year’s topics: Circular Economy, Digitalisation and Climate Protection, which are recent global hot topics which every industry is working hard on.

KUNG HSING at K 2022: Blown Film Trends for Food Packaging Films to be More Productive and Energy Efficient

Food packaging film is the largest application in blown film products. When the market gradually accepts three-layer co-extrusion to manufacture food packaging films, Kung Hsing (KUNG HSING PLASTIC MACHINERY) believes that five-layer co-extrusion will be a better and more favorable option in the future.