リサイクル機械および装置

HOT NEWS

BoReTech: The Leader in Achieving Food-Grade Recycled PET Pellets Technology

With the growing global demand for environmental protection and sustainable development, plastic recycling has become a key focus across various industries, especially in the beverage and food packaging sectors. These industries have particularly high standards for plastic recycling, especially for food-grade recycled PET materials, which must meet strict safety and quality requirements.

How to Choose the Right POLYSTAR Recycling Machine Based on Your Plastic Waste?

Follow the guidelines to choose the right POLYSTAR plastic recycling machine that processes your plastic waste efficiently and with a high yield.

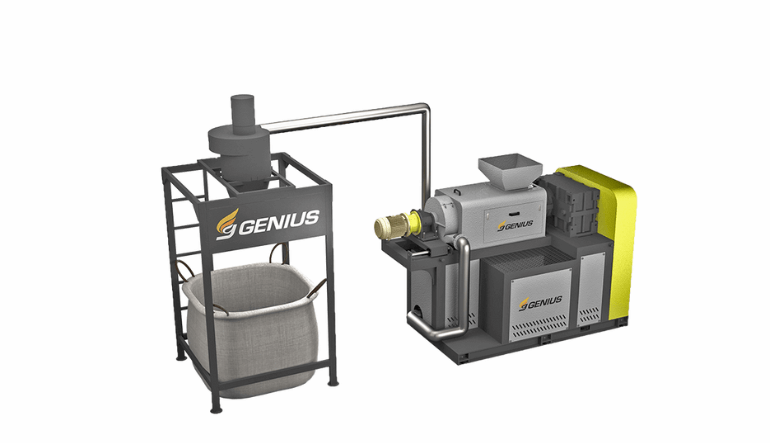

How Screw Press Dewatering Machines Are Transforming Plastic Film Recycling

Plastic waste has become a major environmental challenge, particularly with the growing use of plastic films in agriculture, packaging, and various industries. Recycling plastic films such as agricultural film and stretch film requires efficient dewatering to improve material quality and reduce waste. Among the most effective solutions is the screw press dewatering machine, designed to extract moisture from plastic films during the recycling process. In this blog, we’ll explore how screw press dewatering machines are transforming plastic film recycling, boosting efficiency, and contributing to a more sustainable future.

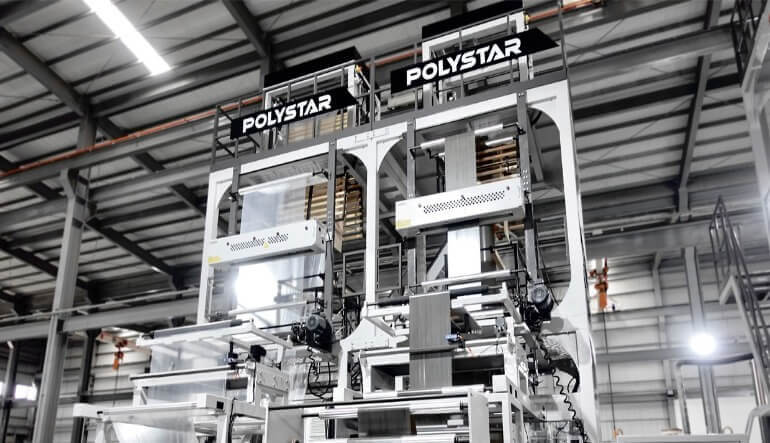

Advanced yet Easy-to-Use Blown Film Extrusion Technology – Key to Eco-friendly Packaging

Eco-friendly packaging is no longer just a trend but a necessity for both environmental and economic sustainability. Blown film extrusion, a key process in packaging film production, must continuously advance to meet the growing demands of the market.Let’s explore how POLYSTAR is innovating its blown film extrusion technology to support the development of eco-friendly packaging solutions.

Tips for Choosing a High Quality PVC Pelletizing Extrusion Line

Polyvinyl Chloride (PVC) is the world’s third most-widely used synthetic plastics succeeding to polyethylene (PE) and polypropylene (PP). The annual demand for PVC keeps increasing. Usually, the PVC products are made by processing the PVC materials in a pellet form that is obtained by a PVC pelletizing extrusion line. Due to facts of that PVC polymers are sensitive to thermal & shearing stress, characteristic considerations on the mechanical and controlling aspects are critical for a high performance PVC pelletizing extrusion line.

From Waste to Worth: Genius Machinery’s Green Engineering

GENIUS Machinery is renowned globally in the plastic recycling machinery market for its advanced technology and customized solutions. Ever since it started, GENIUS has not only focused on environmental protection and the circular economy but has also been dedicated to comprehensive factory planning for plastic recycling systems. With over 40 years of experience in the design and manufacturing of recycling machinery, the company offers a complete range of solutions, including plastic washing lines, recycling machines, pelletizers, squeeze dryers, crushers, and shredders. Worldwide Market Deployment: Strengthening Global Presence

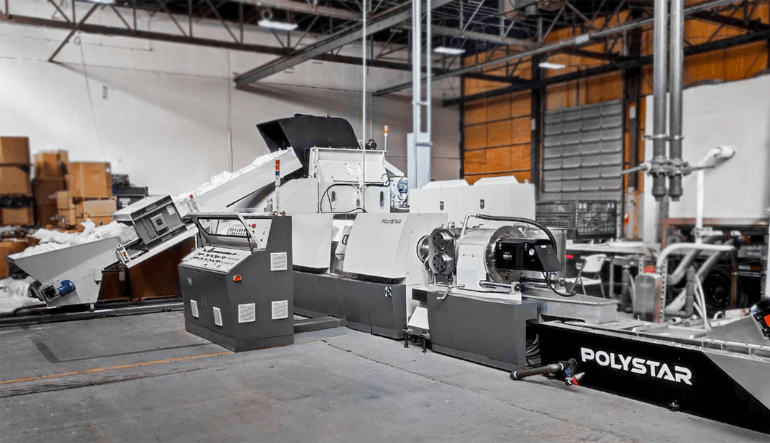

BDB Recycling Leads the Way with POLYSTAR's Innovative Solutions

POLYSTAR is dedicated to creating innovative pelletizing machines that empower businesses to contribute to a more sustainable future. We'd like to highlight one of our valued customers, BDB Recycling, located in Ohio. BDB Recycling shows how our pelletizing machines can revolutionize LDPE/HDPE recycling operations, not only boosting their business but also paving the way for a more circular plastics economy across the US.

Plastic Pelletizer Comparison for In-house Plastic Film Recycling

In-house plastic film is usually clean and can be reprocessed right away without extra procedures. But what kind of recycling equipment you should invest in to make the best use of it? For in-house plastic film recycling, POLYSTAR has two recommended solutions: the Cutter-compactor Plastic Pelletizer, Repro-Flex, and the Air-cooled Plastic Pelletizer, Repro-Air. Both recycling machines can process HDPE, LDPE, and LLDPE clean post-industrial plastics like film, bags, T-shirt bag cut-offs, and edge-trim waste. However, Repro-Flex can deal with more kinds of plastics such as PP, PS, PA, etc. Let’s take a closer look at what they feature and their advantages, which are the main differences between them.