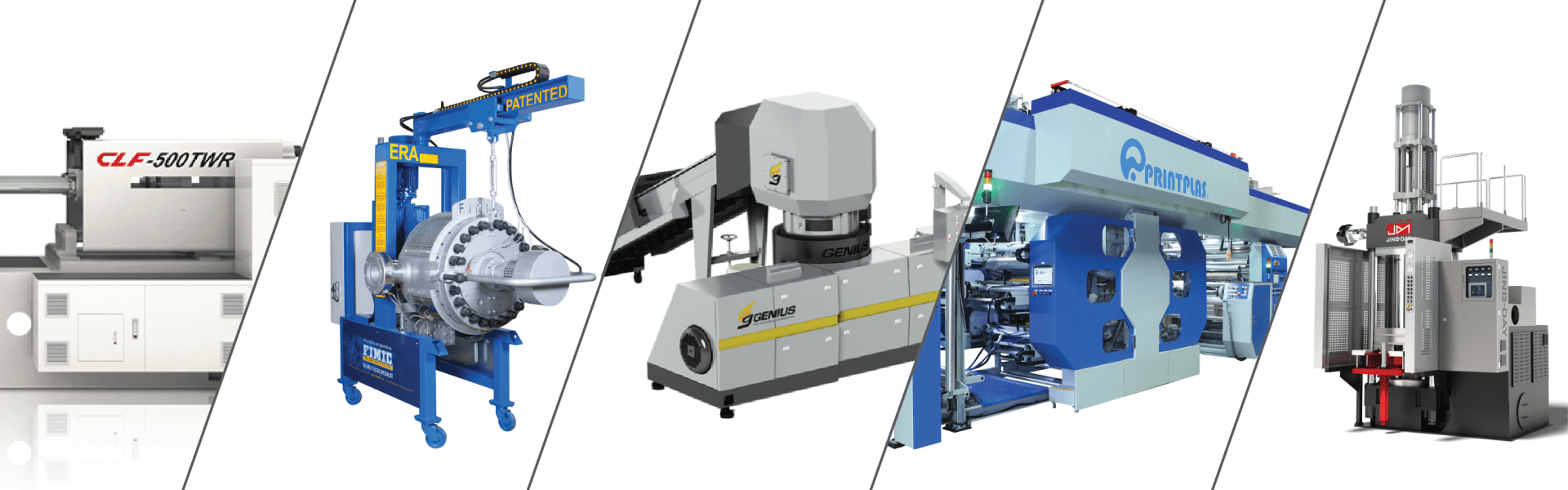

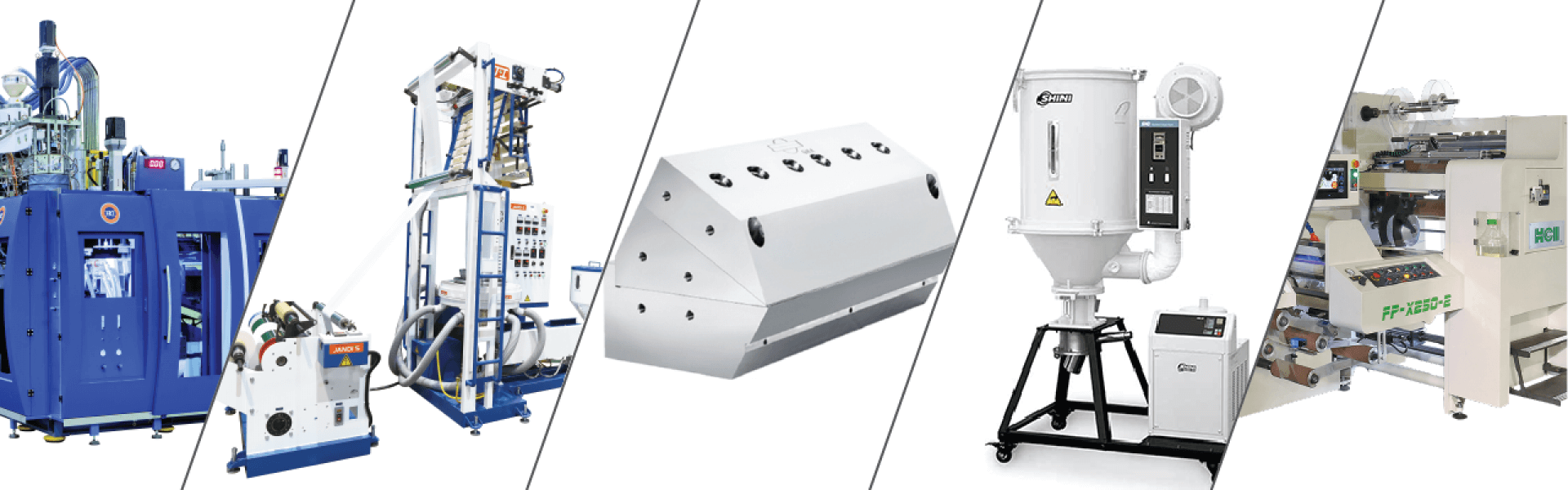

Taiwan Supplier Collection

Seeking appropriate suppliers by watching videos on PRM Media Channel which is collecting over 600 videos and various manufacturers. You could WATCH and SHARE anytime and anywhere.

PRM Media Channel

Media platform for the Plastic & Rubber Industry

PRM Original Collections - What To Say Program, Industry Insights and 15 Category Machinery Videos, International/Local Exhibitions and Interviews videos for worldwide professionals in the field.

Watch the way you want on any of your devices.

Watch the way you want on any of your devices.

Digital Marketing on Social Media Platforms

PRM creates value for Client's Promotion and Brand Awareness, and Technological Trends within the Industry Through Posts and Videos on Facebook, LinkedIn and YouTube Channel.

Global Marketing

The Information Online Has Allowed Us To Connect or Bridge The Gap Between Domestic Manufacturers and Overseas Buyers.

Fast, Reliable and Convenient.

Fast, Reliable and Convenient.

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS.

HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

High Speed & High Capacity Flat Yarn Making Machine | FOR DAH

The FTH-350 & FTH-500 & FTH-650 Tape Stretching Line are the ideal machine to produce high quality and precision cross winding packages of PP/HDPE flat tapes.

Our High Speed Flat Yarn Making Machine is engineered for maximum efficiency in producing high-quality PP/HDPE flat yarn. With advanced technology and robust construction, this machine offers superior performance in both speed and capacity. Key features include:

- High-speed production capabilities

- Advanced control system for precise operation

- Durable components for long-lasting use

- Energy-efficient design

Exclusive Interview: Jawhari Kamil on the 20th Saudi PPPP and Vision 2030

Join host Jason as he sits down with Jawhari Kamil, chief organizer of the 20th Riyadh Expo, for an insider’s look at this landmark event. In just a few minutes you’ll learn: What makes the 20th Saudi PPPP and how it reflects Saudi Arabia’s rapid industrial momentum Kingdom Vision 2030 in action—why national transformation goals are shaping every corner of the show Sustainability in focus: from low-carbon solutions to green partnerships that matter A surprise reveal: Jawhari hints at a major collaboration with a world-famous exhibition coming in 2026—watch to the end to find out which one! Whether you work in plastics, packaging, or any sector eyeing the Middle East, this interview delivers fresh insights you won’t want to miss.

High Speed Side Sealing Machine with Wicketer | LIAN YOU

High Speed Side Sealing Machine with Wicketer

Exploring the Future of Plastics Industry with Juan Eduardo Zarate | 2025 PLASTIMAGEN Interview

What’s next for the plastics industry? At 2025 PLASTIMAGEN, PRM-Taiwan interviews Juan Eduardo Zarate to uncover key insights into this year’s exhibition!

Interview Highlights:

How big is PLASTIMAGEN 2025? Discover the scale and number of exhibitors at this leading plastics event.

Celebrating 25 Years: Special activities marking the 25th anniversary of PLASTIMAGEN!

ESG & Sustainability: Plastics remain essential—how can we improve recycling and promote sustainability? ???? Subscribe to PRM-Taiwan for exclusive industry insights!

Injection Molding Solution | Plastic Injection Molding Machine Manufacturer | CLF

Chuan Lih Fa Injection Molding Machine at steady development of injection molding fields. With strict standards of the quality and the clamping force of the machines, combining high-tech European and Japanese microcomputer controllers, our electric injection molding machine adopts German Siemens controlling system as well as servo motors. The innovative structural design makes Chuan Lih Fa a leader in this industry.

Rubber Injection Molding Machine | JING DAY

Machine for natural, synthetic, oil resistant,heat resistant and reclaimed rubber.

High bed structure with direct clamping.

PLC and HMI functional control as standard specification.

Direct and indirect clamping structure.

Specialized nozzle design to prevent material overflow.

Specialized feeding device.

2024 TaipeiPlas International Plastics & Rubber Industry Show| Geording

In this video from the 2024 TaipeiPlas International Plastics & Rubber Industry Show, we present Geording’s machine designed to support green policies. With a self-cleaning screen changer, their equipment helps customers enhance efficiency and focus on green recycling development. Geording has maintained a long-term working relationship with Polaris, and we explore their experience with our services. Watch to learn more about Geording's commitment to sustainability in the plastics and rubber industry!

2024 CHINAPLAS Interview | Shubham Extrusion

We were delighted to have CHINAPLAS at the ETERLONG booth and meet their largest buyer in India for an interview with us. Mr. Nirav Shah shared that 15 years ago, TAIPEIPas found their trusted partner through PRM-TAIWAN

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023!

Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer.

Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage.

The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc.

Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

Sharing Session of Composite Testing and Regulation | PIIF

引言人:ZwickRoell 台灣分公司 潘東生 總經理

報告人:ZwickRoell 德國總部 全球複材產業經理 Dr. Hannes Körber

《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台

塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

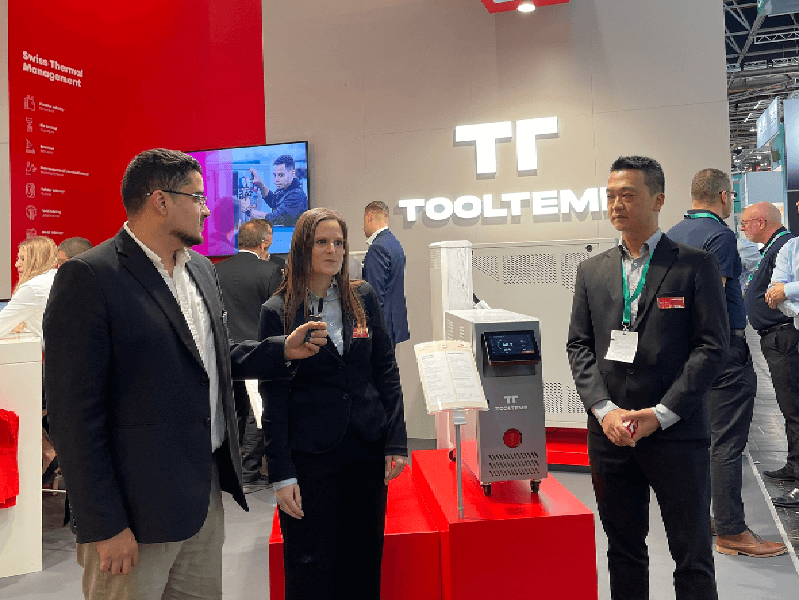

Temperature Control & Cooling Units at K 2022 | TOOL-TEMP

It's PRM's honor to interview Jasmine Koller, CEO of Tool-Temp AG, and Allen Tsai, General Manager (Taiwan), which gave us insightful sharing about their products and perception of K 2022 and of the post-pandemic era.

Surface Modeling 3D Printing | time lapse | Everplast

Surface Modeling 3D Printing | time lapse | Everplast

①The EM3-3505-CMT is an industrial pellet 3D printer manufactured by Everplast from Taiwan.

②This 3D printer is able to utilize compound cement raw material to build products or samples.

③The standard formulation database and material bank are provided along with the 3D printer.

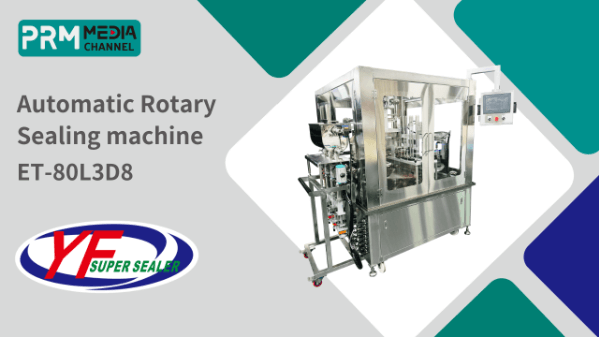

Automatic Rotary Sealing machine(Bowl/Cup) Manufacturer | ET-80L3D8 | YF-SUPER SEALER | Y-FANG

Y-Fang Automatic Rotary Sealing Machine (ET-80) is designed to provide seamless and efficient sealing for bowls and cups. This advanced machine offers a fully automated process, from product loading to precise sealing, ensuring a secure and airtight finish every time. Its compact design is ideal for businesses seeking to maximize efficiency while maintaining high standards of hygiene and product quality. With easy operation and robust construction, the ET-80 is the perfect solution for streamlined packaging in the food and beverage industry.

Application

✔️Suitable for beverages, Pudding, Jelly, Fast-food, Snacks, Various prepared foods for the microwave, Seasoned frozen food, Pickled foods, Seafood, processed agricultural products, etc. Which load into the cup and tray.

✔️Sealable material: PP, PE, PS, PET, HDPE, EPS, PSP, Aluminum foil, Paper box, etc.

✔️For smaller working spaces but higher capacity.

Y-fang Group was established in 1985, specialize in the design and manufacture of sealing machines for various industrial applications. With over years of manufacturing experience, we are able to produce a wide range of tray sealing machines with a capacity of 450 to 600 pieces per hour.

Our machines can perform a variety of different functions such as auto-dropping, piston filling, date printing, vacuuming, and gas flushing (MAP: Modified Atmosphere Packaging). Furthermore, we are also able to provide our customers with OEM, ODM, and OBM manufacturing solutions. Our products have been exported to countries over the world, including Europe, Asia, Africa, and America.

Exploring the Future of Packaging Machinery with Thomas Dohse | Shanghai swop Interview

In this exclusive interview at Shanghai swop, we sit down with Thomas Dohse, a key figure from interpack, to dive deep into the future of packaging machinery and the emerging trends shaping the industry. Discover the fascinating highlights of the swop exhibition, including innovative technologies and unique insights into the latest advancements. Thomas also shares his perspective on the resurgence of globalization, which has taken a new form through fragmented and decentralized transactions, creating fresh opportunities for businesses worldwide. Finally, Thomas gives us a sneak peek into the 2026 interpack, unveiling its central themes and what we can look forward to in this global event. Don’t miss this insightful discussion that combines cutting-edge trends with a vision for the future of packaging!

Film Extrusion Equipment at K 2022 | GMA

It was a great honor for PRM to interview the General Manager — Howard Chao from GMA Machinery.

He shared his insight about how the Russo-Ukrainian War affected Europe Energy Policy and the European market. He's also looking forward to having cooperation opportunities with new partners.

For more information, check the video!

T-Shirt Bag Making Line with Carton Packaging Line|JIT-SS 4 sets full auto. in-line|JANDI'S

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine

00:00 Opening

00:08 Blown Film

00:28 Machine current speed

00:37 Cutting, Sealing & Punching

00:54 Sending finished bag to Carton Packaging Section

01:07 Take-up Tower & Printing

02:27 Carton Packaging Proccess

05:04 Ending

---

Website : www.jandis.com.tw & www.inflationmachine.com

Facebook : www.facebook.com/JANDIS.JIT

Email : [email protected]

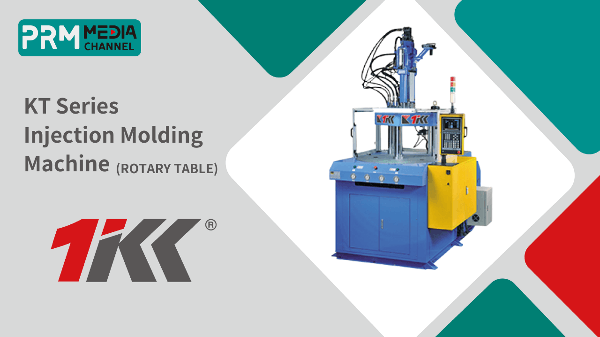

KT Series Injection Molding Machine (ROTARY TABLE) | TAIWAN KINKI

KT Series Injection Molding Machine

Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions.

Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items.

Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production.

There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Die Cutting Machine Manufacturer | Yicheen

Yicheen High Precision Die Cutting Machine offers a variety of options, such as CCD Auto Positioning, Auto movable Stacking, etc., click the link to see more Die Cutting Machine info: ???? https://bit.ly/3qbjbtf

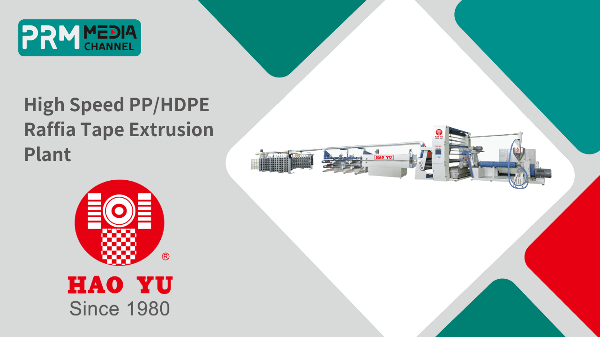

High Speed PP/HDPE Raffia Tape Extrusion Plant | Raffia Tape Extrusion Line | HAO YU

【New generation high speed PP/HDPE raffia tape extrusion plant - GV series (Green Veloz)】

/ Raffia Tape Extrusion Line/Plant Features - (HY7/SP-80GV) / ⚡️Suitable for making 100% recycle PP/HDPE materials ⚡️Finish products complies with the requirement of GRS(Global Recycled Standard). ⚡️Meet the requirements of companies interested in selling their products to ESG approved companies. ⚡️Rapid color changing.

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

2024 NPE Orlando Interview | GENOX USA

In this interview with Genox USA, we talk to Mr. O' Donnell about how Genox provides valuable machines and solutions for the plastic and metal recycling markets in America. He shares insights into the company's offerings and outlines their future plans for expansion in North America and Latin America.

2023 VietnamPlas Interview | CLF

It's our great honor to interview Jenny from CLF, introducing their injection molding machine TWII 250.

K 2022 ON-SITE TOUR | PRM

Can't attend K 2022 in person? PRM will show you the most interesting exhibition highlights on【K SHOW 2022 ON-SITE TOUR】

Taiwanese manufacturers are gathering at K 2022 and showcasing their new technique of plastic & rubber machinery.

You can also feel the good vibe from the show.

【Video Outline】

0:00 Introduction

0:16 CHAO WEI PLASTIC MACHINERY | Plastic Converting Machines

0:37 YE I MACHINERY | Plastic Recycling & Material Processing Machinery

1:36 HO HSING PRECISION INDUSTRY | Parts and Components

2:06 HUARONG GROUP | Injection Molding Machines

2:50 SUNKIST CHEMICAL MACHINERY | Thermoforming Machines

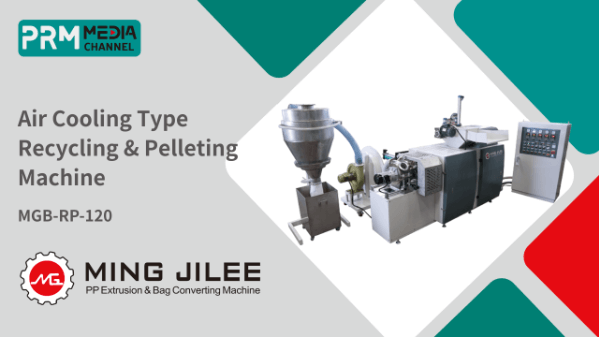

3:17 MING JILEE ENTERPRISE| Extruders & Extrusion Lines

3:41 QUEEN’S MACHINERY | Extruders & Extrusion Lines

3:52 CHI CHANG MACHINERY | Extruders & Extrusion Lines

4:17 HSIN LONG | Molds & Dies 4:38 FORMAX | Auxiliary Equipment and Integrated Automation

4:46 YEN SHENG MACHINERY | Extruders & Extrusion Lines

5:01 BOTHEVEN MACHINERY | Auxiliary Equipment and Integrated Automation

5:20 GENIUS | Plastic Recycling & Material Processing Machinery

5:40 JUMBO STEEL | Extruders & Extrusion Lines

6:10 WORLDLY INDUSTRIAL | Printing Machinery 7:00 PRM TAIWAN

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine.

Email: [email protected]

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design.

Stopless roller adjustment design.

Plate wheel outer finetune mechanism

Quick release ink rollers.

Printing wheel clean system (200 mm dischargeable)

Sleeve Printing

Plate wheel pre-register mechanisim.

2024 CHINAPLAS Interview | JANDI’S

We are here with Tony from JANDI’S at the CHINAPLAS. JANDI’S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag-making, printing, and recycling machines. They obtained more than 30 patents for plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI’S proposes an idea about green innovation. The company develops JIT series integrated plastic bag-making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI’S added the automatic packaging part to JIT series.

Positioning swop as a Packaging Industry Leader: Insights from Adsale’s VP, Rita| Shanghai swop 2024

In my latest interview at swop, I had the honor of speaking with Rita, Vice President of Adsale, one of the key organizers of this impactful exhibition.

Rita shared her perspective on how Adsale strategically positions swop as a cornerstone for the packaging industry, fostering meaningful connections and driving innovation. She also revealed Adsale’s core mission behind organizing exhibitions like swop and how they contribute to shaping the future of the industry.

Curious about how swop creates value for packaging professionals worldwide and what to expect from this pivotal event? Don’t miss

Rita’s insights and her vision for swop’s role in the global packaging ecosystem.

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

2024 NPE Orlando Interview | ISI

I had the pleasure of meeting Mr. Joe Whann at NPE Orlando. Joe is not only brilliant but also incredibly friendly! He provided an insightful introduction to the wide range of services offered by ISI and shared how they have become a leading agent in the USA. Don't miss out on learning about their impressive journey and expertise!

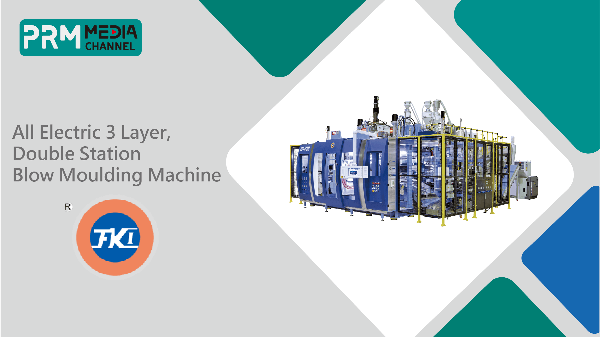

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

All Electric 3 Layer, Double Station Blow Moulding Machine for plastic bottle making

Energy Saving

Power consumption 40~50%↓

Production output 20~25%↑

ECO

No hydraulic oil, no pollution,

Noise level 20dB reduced.

Industry 4.0

Smart manufacturing, with SCADA system.

Product (Jerry Can) 15lt/20lt

Product Weight (N.W) 550g/680g

Product Rate 270bph

Avg. Power Consumption 67kW/102A

Service Circuit Breaker 211kW/320A

Machine Dimensions (LxWxH) 10x8x4.4m

More information, please visit us at:

www.fki.com

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw

/ Automatic Log Roll Cutting Machine Features /

Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down.

PLC control system Auto change cut size setting in the same shaft.

Precise and smooth positioning.

Multi-speed cutting rolls to improve operating efficiency and maintain high quality.

The blade has different angle changes according to different materials, reducing the number of tool changes.

/ Advantages of Yicheen /

Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions.

/ links of Yicheen /

Contact us: https://bit.ly/3q8KLaK

Subscribe us: https://bit.ly/3wGjjU3

Product Info: https://bit.ly/3tU2QdK

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry.

What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected?

Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide.

Topics Covered:

U.S. reciprocal tariffs overview

Strategic moves for manufacturers in 2025

Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

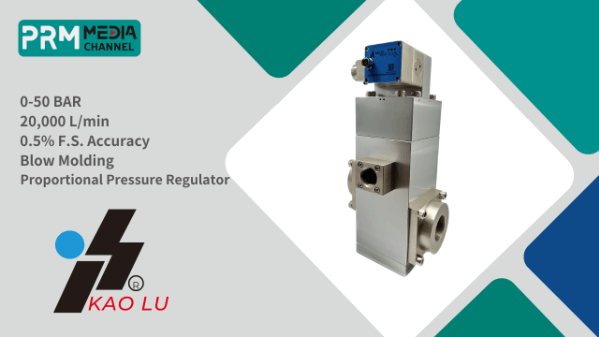

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer.

With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world.

【Video Outline】

Company Introduction

Product Application & Competitiveness

Product Introduction

Main Customers

Application on Medical and Biotech Equipment

Application on Plastic and Rubber Equipment

Advantages of the Era of Industry 4.0

Contact Information

High Speed Slitting Machine - S2A Series | YICHEEN

YICHEEN is a professional equipment supplier that specializes in soft-material cutting technology, including die cutting, sheet cutting, slitting and laminating. Since 1979 we have been supplying soft material cutting machinery. This has now transformed into state of the art high-precision customized cutting equipment, which meets worldwide standards and guidelines.

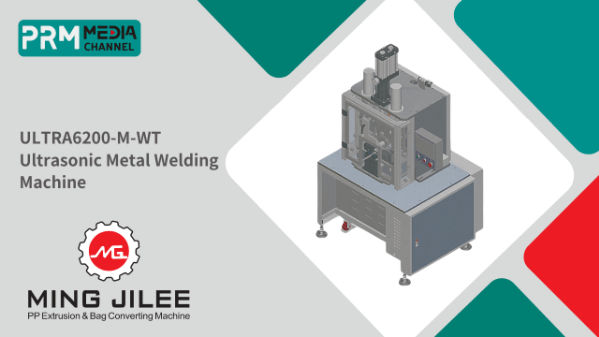

Ultrasonic Metal Welding Machine-ULTRA6200-M-WT | MING JILEE

ULTRA6200-M-WT

Ultrasonic Metal Welding Machine

2024 InterPlas Thailand Interview | SHINI

In this video, we have the pleasure of interviewing Siwakorn Tachapanich (Bank), the Sales Executive of Shini's local agent in Thailand. Shini boasts an exceptional sales and engineering team in Thailand, always ready to provide top-notch service whenever needed. Watch as we delve into their operations, commitment to customer satisfaction, and the unique advantages they bring to the market.

ISOTHANE TPU Foam beads | GRECO

Expanded TPU Low density High elasticity ISOTHANE TPU Foam bead has light density and high elasticity even at -25°C. It even withstands prolonged and repeated compression without permanent deformation. TPU Foam bead (expanded thermoplastic polyurethane) offers a perfect combination of soft texture and great elasticity. ISOTHANE TPU Foam bead - colorful foam beads with high elasticity, customized different color and particle size for lightening era. ISOTHANE TPU Faom bead Suitable for footwear materials, Buffer device for sports, Bicycle saddles , Running tracks, Airless tires. → For more information please check GRECO official website: https://reurl.cc/OVDRy

2024 CHINAPLAS Interview | GRECO

GREAT EASTERN RESINS | TPU, the best products of Great Eastern Resin. Those can be used in many different fields from automotive to medical. Inquiry & More Info: https://www.prm-taiwan.com/shorturl/CMbn9wr5

Extrusion Blown Film Lines for Flexible Packaging | KING PLUS

Three-layer blown film machine for lamination film

Including:

Auto air ring

Gravimetric dosing system

Internal bubble cooling system (IBC)

In-line thickneess gauge

Oscillating haul-off

Back to back double winders

Customized blown film machine to meet your need!

Welcome to contact us!

Proportional Pressure Regulator Valve | QKL-B2T+External Pressure Sensor | KAOLU

00:00 QKL-B2T Proportional Pressure Regulator Valve + External Feedback Pressure Sensor Product Introduction

00:21 QKL-B2T+External Feedback Pressure Sensor Description

00:29 Product Function: Boost Flow

00:40 Product Feature: Remotely controls cylinder pressure

What is a Proportional Pressure Regulator Valve?

In pneumatic world, a proportional pressure control valve is used to control downstream air pressure with an electronic signal. The input electronic signal is proportional to the span of the output pressure. For example, 0-10VDc of command signal corresponds to the output pressure span of 0 - 10 bar, with linear proportion relationship.

Type of Proportional Pressure Regulator Valve?

Kao Lu offers three types of electronic proportional pressure regulator: pressure ranges from vacuum -1~0bar, low pressure 0~2bar, 0~4bar, 0~8bar, medium pressure 0~16bar, 0~30bar, up to high pressure 0~70bar. In the high pressure control, the resolution can reach 0.5~0.6 bar.

Proportional Pressure Regulator Valve Working Principle?

Proportional Pressure Control Valve adopts a closed loop design and consists of two solenoid valves, an internal pressure sensor and an electronic control; according to an analog signal input, one solenoid valve is used to control the air intake and the other is used to control the pressure. Both valves work together to achieve a precise proportional pressure control. The proportional pressure regulator adopts two types of input signals: 0-10VDC or 4-20mA, and three types of monitor output signals: 1-5V, 0-10V or 4-20mA.

Innovative Technology in Plastic Recycling | BoReTech-

BoReTech is a leading company in the plastic recycling industry. With more than 30 years experience in the industry, BoRetech is introducing its brand new designed ES process.

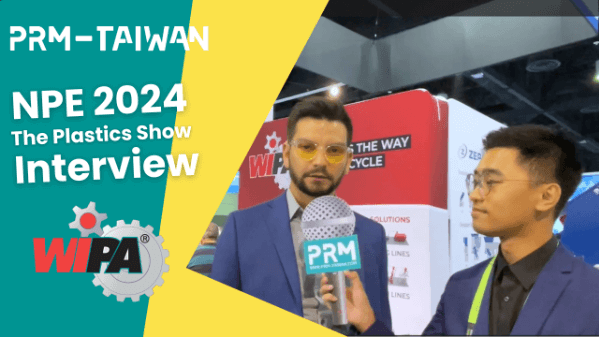

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

Plastic Bag Folding, Sealing & Cutting Combo Machine

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, they are dedicated to making technological innovations and manufacturing packaging machines.

World Steel on PRM: https://www.prm-taiwan.com/shorturl/Qrm7p5Qg

Two Platen Injection Molding Machine - 3500TPII | CLF-

➡️ Maximum injection weight 34 KG.

➡️ High stability, High efficiency, High energy saving..

➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy.

➡️ Direct pressure clamping to make the mold evenly stressed.

➡️ Smooth, stable and powerful.

➡️ Uniform tension force on tie bars for dramatic increase of service life.

➡️ Simplified construction with no wearing problem on toggle clamp.

Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

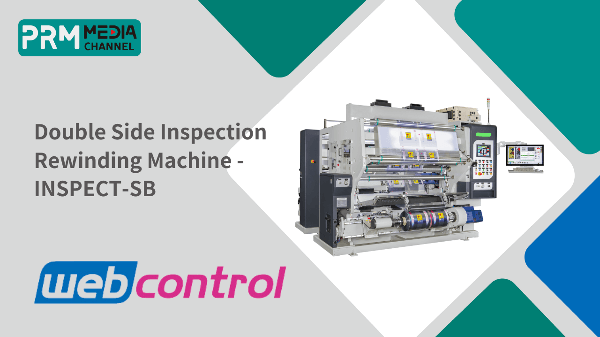

Inspection Rewinding Machine (INSPECT-SB) | WEBCONTROL

The double side inspection rewinding machine is designed print roll inspection. This model is able to inspect both sides of the material simultaneously to ensure the best quality in the minimum time.

2024 CHINAPLAS Interview | HCI

We are here with Terence from HCI Converting Equipment at the CHINAPLAS. HCI is a specialist in the Converting Equipment and Slitter Rewinder machinery, able to provide from a single machine to whole plant equipment. We heard very valuable information from Terence, thank you so much!

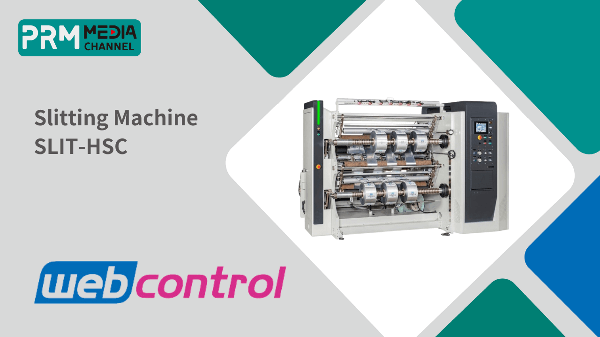

Slitting Machine (HS-Compact) | WEBCONTROL

The SLIT-HSC series slitter is new compact type to save the working space. From the unwind side, the web is guided middle to the main machine, easy access to the slitting section and eliminates dust collection/hazarded steps. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MNI touch screen. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

2023 VietnamPlas On-site Tour | PRM-TAIWAN

VietnamPlas is an important exhibition in the plastic and rubber industry.

Watch the on-site tour video from VietnamPlas for more information!

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

Product (Jerry Can) 15lt/20lt

Product Weight (N.W) 550g/680g

Product Rate 270bph Avg. Power Consumption 67kW/102A

Service Circuit Breaker 211kW/320A

Machine Dimensions (LxWxH) 10x8x4.4m

More information, please visit us at:

www.fki.com

[email protected]

2024 InterPlas Thailand Interview | Chang Horing

We had the pleasure of interviewing Chang Horing Rubber Group, a leader in the rubber compound industry with over 20 years of experience, at Thailand InterPlas 2024. In this engaging conversation, they shared their expertise in developing and customizing rubber compounds for various industries, including automotive, chemical, heavy-duty, food, and water sectors. Chang Horing's dedication to quality and precision is evident in their state-of-the-art facilities, equipped with advanced systems and instruments to ensure high-quality consistency. They also discussed their future plans and initiatives related to Environmental, Social, and Governance (ESG) practices, highlighting their commitment to sustainability and innovation. We thank Chang Horing Rubber Group for sharing their valuable information and look forward to seeing their continued success in the industry.

Double Lines T-Shirt Bags Making Machine:ST-88-G2 | COSMO

Fully Automatic High Speed Double Lines T-Shirt Bags Making Machine with Hot Slitting & Side Gusseting Device.

Model : ST-88-G2 Machine Features: https://www.cosmo886.com.tw/en/products_i_High_Speed_T-Shirt_Bag_Making_Machine_with_hot_Slitting_and_Side_Gusseting_Unit_ST-88-G2.html

➤Contact Us COSMO MACHINERY CO., LTD. Web: https://www.cosmo886.com.tw

2024 CHINAPLAS Interview | ANIPAC

It’s our great honor to interview Mr. Aldimir Torres Arenas from ANIPAC He shared his insight for the China and Mexico market. Check our video for more information!

All-Servo Drive T Shirt Bag On Roll Bag Making Machine ft. Swing Type Feeding System | PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2

Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats.

【T-Shirt Bag On Roll Making Machine Features】

High speed Continue feeding system available in 200/250/300rpm systems.

Tension-less sealing avoids sealing line pull & elongation for high-speed production.

Rotary Die cut by Magnetic cylinder with simple die cut blade exchange.

Inverter controlled feeding matching main machine speed for easy operation without manual adjustment.

Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2)

Equipped with LCD touch panel, easy to operate

Switch control to exchange bag making process without adjustment

Bag re-wind in roll , paper CORE insert in line automatic

End of Film, core auto STOP

【Machine Available System】

Tension-less sealing

T shirt bag on roll

Flat bag on roll

S type bag on roll

【Company Intro】

“PAL- Working with you to create all types of bag making automation solutions!”

Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

CHINAPLAS On-site Tour Hall No.7 | PRM-TAIWAN

What! You don't know which manufacturers are participating CHINAPLAS? Hurry up and check out the CHINAPLAS on-site tour brought to you by PRM.

Let Alice show everyone the charm of the CHINAPLAS. Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

->PRM booth number: 7G01

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

TAIPEIPACK 2023 On-site Tour| PRM-TAIWAN

TAIPEIPACK 2023 exhibition tour is coming!

Follow Daniel to learn about Taiwanese packaging manufacturers And the first-hand industry information!

Plastic Recycling in Japanese Market at K 2022 | POLYSTAR

We were glad to have an interview with Mr. Kenji Murai, agent of POLSTAR in Japan, who shared his observation of plastic recycling in the Japanese market and his experience doing machinery business.

CHINAPLAS On-site Tour Hall No.1-6 | PRM-TAIWAN

Hello everyone! It's been a long time since last CHINAPLAS Let one of partner from PRM—— Joey Show you all the fantastic things at CHINAPLAS Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

Market Observation of Turkish Market | PRM What To Say EP19

It's a great honor for PRM to share the observations of the Turkish market, including the economy, cultural influences, industry trends, investment opportunities, etc.

To know more about the Turkish market, watch the video!

2024 Expo Plasticos Guadalajara | Organizer Executive Jeorge

Dive into our exclusive interview from the Mexico Plastics and Rubber Industry Expo 2024, where we explore the event’s commitment to sustainability and circular economy practices. This year’s expo features 100% recyclable carpeting, aligning with ESG goals and showcasing the industry’s push toward a greener future. The event has attracted numerous professional buyers, with a bustling atmosphere fueled by nearby factories and industries in Guadalajara. Join us as we uncover the organizers’ objectives and hopes for this year’s exhibition. After watching, visit our PRM platform for a comprehensive post-show report to see if these goals were met. Don’t miss out on the highlights and insights from one of the industry’s most vibrant events!

Part 2. Theme Forum - Innovation of High-end composites & Key markets | PIIF

《高端複材創新與關鍵市場》

複材自主創新應用

亞洲區域市場潛勢機會

產業整合與優勢創造

主持人:塑膠中心 邱政文 副總經理

與談人:

1. 天力離岸風電科技(股)公司 王柏棋 技術處長

2. ZwickRoell台灣分公司潘東生 總經理

3. 虎科大飛機工程系 王正賢 助理教授

4. 經緯度企業 蔡承穎 董事長

《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台

塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

The Most Reliable PP/PE/PET Woven Bag Machinery Maker | HAO YU

Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturer of PP/PE/PET woven bag machinery and whole-plant equipment. Since its establishment in 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence of HAO YU machines. Our objective is to enhance our present machinery and develop new models that improve the efficiency, product quality and profitability for our customers.

Part 1. Open Ceremony (Strategy & Solution to Sustainability) | PIIF

開場貴賓:塑膠中心 蕭耀貴 總經理

《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台

塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

Garbage Bags on Roll Making Machine:SOSR-1000-2T-R+L

Fully Automatic High Speed Single Line Core-less Garbage Bags on Roll Making Machine with label device Model : SOSR-1000-2T-R+L

• Core-less bags on roll

• Bottom sealing bags with V, C, N, M shape

• Shuttle sealing & feeding system

• Label device

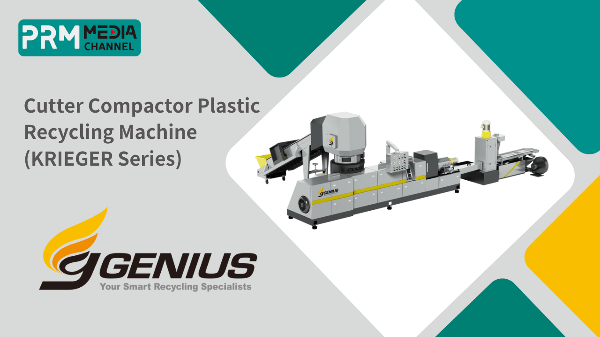

Cutter Compactor Plastic Recycling Machine (KRIEGER Series) | GENIUS

The KRIEGER series cutter compactor plastic recycling machine integrates crushing, extruding and pelletizing in one machine.

A proprietary designed cutter compactor can compact the density of fluffy plastic film to flakes.

It helps to increase the efficiency of extruder. After compactor, the materials are extruded to Genius patented universal joint pelletizing system.

The universal joint pelletizing system can automatically adjust the distance when cutting the polymer to pellets. Significantly reduces manual adjustment error rates.

After cooling, these pellets are sent to centrifugal dryer to remove moisture. A vibrator at next step removes powders or oversized pellets.

Finally, recycled pellets can be reused in different fields, for example, blow film or injection molding industries.

/ Key Features of Cutter Compactor Plastic Recycling Machine /

Energy cost saves up to 20%

Only 1~2 operators are needed to operate the pp recycling machine.

High-speed rotation operation makes the fluffy material compact.

Simultaneous material dewatering.

Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system.

The temperature control is convenient, and the temperature of the crushing barrel is controlled in a stable manner.

Provide customized recycling, sorting, feeding, degassing, filtering, granulating to storage and packaging systems.

Corona Treater | CHAANG HORNG-

.For non-conductive substrates

.400~1600mm treat width available

.One / Two side treatment

.25mm segmented electrode finger

.Φ 2.5” treatment roller

Part 2. Open Ceremony (Advanced Composite Material, Sustainability and Energy Saving) | PIIF

開場貴賓: 塑膠中心 邱政文 副總經理

《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台

塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries.

【Product Appliance】

Beverages

Water

Edible Oil

Daily-used

Cosmetics

【Product Range】

One Stage Injection Blowing Machine

Injection and Bottle Molding Manufacturing

Stretch Blow Molding Machinery Sales / Turnkey Solution

TS Series Models for Lower Production Output (Suggest to new market players)

Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output)

【SS10-rPET Single-stage PET Bottle Blowing Machine】

Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency

Barrier screw with venting capability can effectively lower the energy required for drying

Adopt 4 station design

Non-contact feature

Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

Precision Mold Making & Injection Molding Solutions

Jia Thai Industrial Co., Ltd. Company Profile

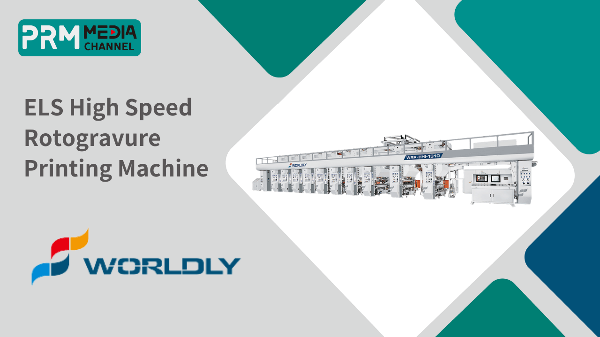

ELS High Speed Rotogravure Printing Machine | WORLDLY-

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY

Machine Specifications

- Max machine speed: 350 m/min

- Web width: 1000 / 1200 / 1300 mm

- Printing cylinder circumference: 350 - 900 mm

- Material diameter: 800 / 1000 mm

- No. Color: 10 colors

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding.

We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

【Product Features】

● Five layers co-extrusion blown film line

● Φ300 mm Die : Production output 600 kg / hr

● Gain in weight gravimetric dosing unit ( Italy made)

● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made)

● IBC computer control system (U.S.A Made)

● Horizontal oscillating take-up unit

● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding)

【Video Outline】

0:00 Welcome to K 2022

0:24 Introduction of Kung Hsing Machinery

0:53 Highlights of Kung Hsing at K 2022

1:54 Applications of KS Blown Film Machines

2:34 Upgrade of Three Layer Blown Film Machine

5:38 Strategy and Implementation to ESG

6:51 Customer Oriented Service

7:54 Advantages of Taiwanese Supply Chain

8:54 Occurrences affect Global Market

10:04 Development Trends of KS Blown Film Machine

11:07 More information on PRM B2

Bag on Roll Making Machine-Draw tape Garbage Bag|Plas Alliance Ltd.

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers.

Learn More :

• Bag on Roll Making Machine|Draw tape G...

------------------------------------

Draw tape garbage bags are advanced type of garbage bags which has strong tensile strength and puncture resistance, and controlled elongation for volume. The draw tape can be pulled and knotted for secure closure. Bag on roll are good and compact for transportation and end use for household consumers.

- Bag making application

- Draw tape garbage bag on roll

- Folded draw tape garbage bag

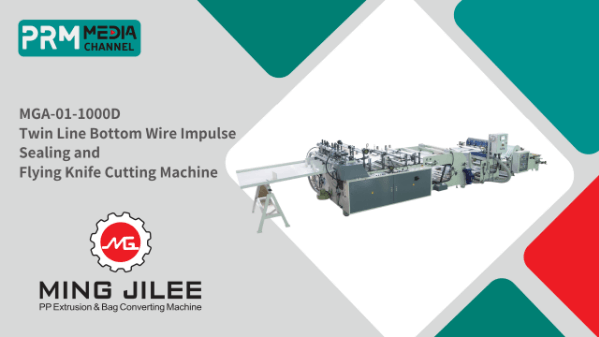

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

2024 Expo Plasticos Guadalajara | HAO YU PRECISION MACHINERY INDUSTRY CO., LTD.

Join us as we interview Hao Yu Precision Machinery Industry Co., Ltd. at ExpoPlasticos 2024!

We shine a spotlight on Hao Yu’s expertise in manufacturing PP/HDPE woven bag-making machines. With 26 years of local experience in Mexico, Hao Yu’s unique advantage lies in its direct communication with customers, ensuring tailored solutions to meet their needs.

Their commitment to sustainability, combined with a strong willingness to engage directly with local buyers, enables them to deliver highly customized solutions that meet diverse needs.

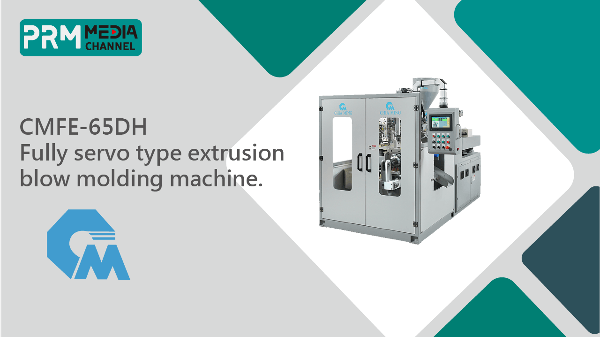

Full Electric Co-EBM with visi strip (4 head double station) | CM-90.55FVH2D | Chia Ming

CM-FE90.55FVH2D

Full Electric Co-Extrusion Blow Molding Machine - Continue extrusion with horizontal movement and toggle clamping. Fully automatic and highly efficient production.

--------------------------------------------------

Why Go Full-Electric?

► Energy savings 20%~70%

► Precise and more efficiency

► No hydraulic, less noise, no oil leakage

► Easy maintenance

--------------------------------------------------

/ Key Features /

★ All-electrics (Fully servo motor driven)

★ Servo Drive Die Head Nodding System

★ Full Electric Parison Control System

★ Crank Type Servo Drive Carriage Movement

★ Visi Strip function

★ Auto deflashing device

★ Backhoff, Germany and Keyence, Japan control system

--------------------------------------------------

/ Other Features /

★ Equipped with robot arm (2D Gripper)

★ Post cooling

★ Auto loading system

★ Residue conveyor to crusher

★ Built by standard components, i.e. Beckhoff, Festo, SMC, Toshiba, Tokimec, Schneider, ABB, Omron, ensuring straightforward maintenance at lower cost and global spare parts availability

--------------------------------------------------

/ Optional equipment or function/

????Support the “Industrial” internet of things. (More info, please contact.)

--------------------------------------------------

/ Application/

Jerrycan/ Food packaging/ drinks/ detergents/ reagents/ cosmetics/ medicines/ engine oil bottles/ lubricants/ jars/ home products/ car parts/ decoration parts...

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor

*Gripper bag transfer system, most advanced design

*Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap

*Union Special Sewing machine customized model available

For more information, visit http://www.botheven.com.tw

EPS Foam Sheet Machine | Plastic Extruder Manufacturer | ChiChang

EPS Foam Sheet Machine can be widely used in packaging materials, such as food trays, eps food Packaging.

Learn more https://www.extrusion.com.tw/en/products.html

Contact Us https://www.extrusion.com.tw/en/contact.html

/ EPS Foam Sheet Machine Features /

Machines provide customized services.

Application: Food Tray / Packaging Material.

Output: From 200 kg/hr. to 720 kg/hr. for EPS.

Configure a color screen to instantly view productivity.

Safe and high quality.

/ About Chi Chang - Plastic Extrusion Machine Manufacturer /

Chi Chang have been committed to the design and fabrication of extrusion equipment for over 45 years. Our user-friendly and performance-oriented innovative technology reduces the operating workload of workers, reduces the operating costs, increases the overall production capacity and this in turn generates more profit. You can rely on Chi Chang to simultaneously secure both profit and quality for our clients.

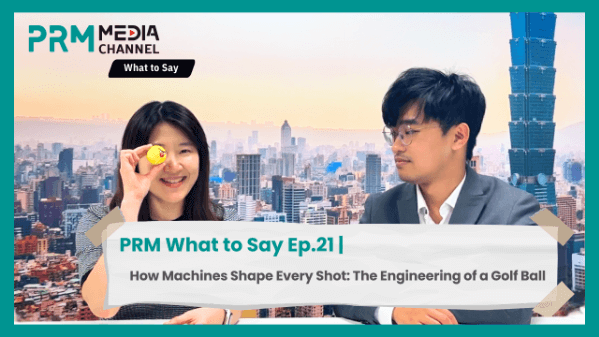

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Second Life to Recycled Plastics | BoReTech

Have you wondered how PET bottles have been recycled? Where do recycled plastics go?

BoReTech is a leading company in the plastic recycling industry, who strives to solve plastic waste and give it a second life.

With more than 30 years experience in the industry, BoReTech is able to process different materials from different countries and gain know-how experiences.

Lately, BoReTech has redesigned their washing line in a smaller footprint, which is 50% less surface area compared to their standard line.

Here are four improvements of the latest washing line called ES-process PET Bottle Recycling System.

Smaller Foot Print

Convenient in Maintenance

Environmental Protection and Sustainability

Quality Improvements

To be a global pioneer in the plastic recycling ingenuity, BoReTech has gradually moved towards the research, development, and design of the all-plastic recycling process.

Let's keep our environment in ecological balance and promote global sustainable development.

【Video Outline】

0:00 Reduction of Carbon Emissions

0:52 BoReTech's Plastic Recycling Solution

1:32 Journey to Plastic Recycling

3:11 Development of BoReTech

3:54 Innovation & Integration to meet food-grade demand

4:38 BoReTech PET Bottle Recycling System

5:10 ES-process PET Bottle Recycling System

7:07 Market share of BoReTech in India & Japan

8:51 Service from BoReTech

9:46 Future Development & Mission

2024 NPE Orlando Interview | PARKER

We had the pleasure of meeting the passionate Mr. CT Teoh at the NPE show. Mr. Teoh gave us an insightful overview of the innovative PET blow molding machine he brought to the event. This cutting-edge machine features single material concept. Join us as we dive into the details and discover the big news Mr. Teoh has to share!

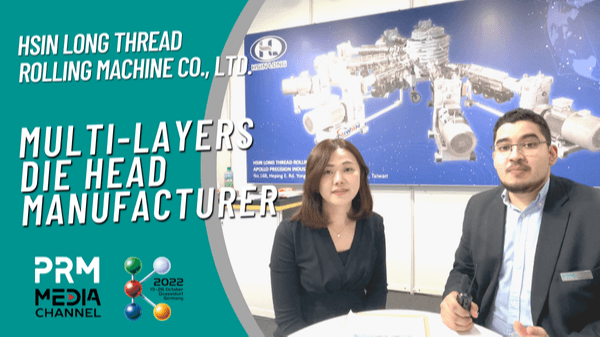

Multi-layers Die Head Manufacturer at K 2022 | HSIN LONG

Hsin Long Thread Rolling Machine Co., Ltd. is knowing for high-quality products, such as blown film machine, extrusion die and extruder filter, and their post-sale service. By interviewing Ms. Sandy Chen, Production Manager, we gained the information about how Hsin Long apply digitalization in their equipment.

Sensing & Polymer Test Equipment at K 2022 | Dynisco

We are glad to have an interview with Bill Desrosiers, Vice President of Dynisco, since our last interview at K 2019.

The industry has been changed a lot due to COVID said by Mr. Desrosiers. Moreover, we had a discussion of how Dynisco implemented trending topics at K 2022, such as Circular Economy, Digitalization and Environment Protection, and applied these concepts in Dynisco products.

2023 IPF Taiwan Manufacturer Interview | POLYSTAR

It is a great honor to invite Sumit from POLYSTAR to share the changes in Bangladesh's industry after the pandemic and the differences between the Bangladesh market and the India market.

All-Electric Injection Molding Machine | TAIWAN KINKI

TAIWAN KINKI(TKC) is pioneer of Vertical Injection Molding Machines for Auto Industry, we were the first in the world to design and manufacture the 1st all-electric vertical injection molding machine for Taiwan and China. TKC works with a wide range of plastic injection materials and molded parts.

【All-Electric Vertical Injection Molding Machine Features】

Low Noise:All process-relevant movements (injection, mold open/close) are executed via electric motors, resulting in quieter and less noisy operation.

High Efficacy:The electric unit is digitally controlled so that the mechanical operation is highly repeatable and precise, and the electrical drive enables the parallel movement of the machine, so the process is faster and more efficient.

Save Water:Fewer components and oil need to be preheated than hydraulic injection machines, thus saving on cooling water usage.

Power Green Energy:No hydraulic system is used, and energy is only used during machine movement, so it can save more energy and achieve power green energy.

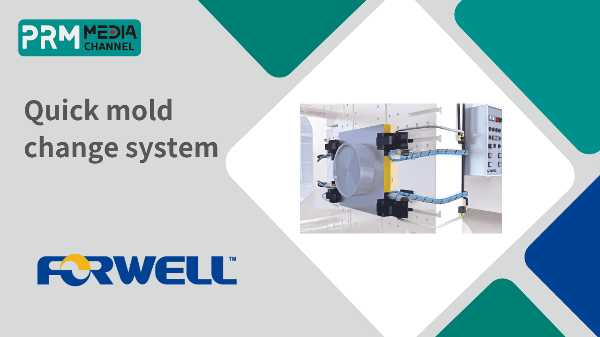

Quick mold change system|QMCS|for Injection molding|Sistemas de cambio rápido del molde|FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety.

Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits.

Indirect Benefits

Die Standardization

Press Standardization

Increased Safety

Improved Working Environment

Increased Competitiveness

Direct Benefits

Reduction in Die Change Time

Efficient Small Batch Runs

Reduced Stock Handling

Higher Productivity and Quality

Reduction in Labor Costs

Gravimetric Technology at K 2022 | MAGUIRE

Founded in 1977, Maguire Products manufactures gravimetric blenders and feeders, volumetric feeders, ULTRA low energy dryers, conveying systems, extrusion control systems, loss in weight extrusion control, and related auxiliaries for Plastic & Rubber industry.

It was a great honor for PRM-TAIWAN to invite Frank Kavanagh — Vice President Global Sales and Tony Tsai — Sales Manager (Taiwan) from Maguire. The conversation was mainly about the biggest challenge during the pandemic and how to integrate product innovation into application of Circular Economy, Digitalization, Climate Protection, which was the 3 main topics of K 2022. In the end, Mr. Kavanagh also talked about their main goal of the attendance. For more information, check the video!

Thermoforming Machine CM 100A with Forming Mould PET Clamshell | HONG ZU

Thermoforming Machine CM 100A with Forming Mould PET Clamshell forming area with 25 cavities per mold the products are formed so perfectly. High-efficiency, high-quality thermoforming mold for customer satisfaction.

ChenHsong CFO Dave:Technology Innovations and Market Insights in Turkey | PlastEurasia Istanbul 2024

At PlastEurasia Istanbul 2024, ChenHsong CFO Dave discusses the company’s long-standing presence in the Turkish market and their latest technological innovations. Dave shares insights on the newest machines domestrate at the event and offers expert views on market direction and industry trends, particularly in the Turkish and regional plastics markets. Watch to learn about ChenHsong's cutting-edge technology and the future of the industry. Like, share, and subscribe for more industry insights!

2024 NPE Orlando Interview | GRECO

Last time at Chinaplas, I interviewed GRECO and gathered a wealth of information. This time at NPE, I had the privilege of interviewing Dr. Wu, a highly professional and humorous gentleman. Watch his passionate reaction as we discuss GRECO USA's development and future plans. Don't miss this engaging and insightful interview!

2023 IPF Taiwan Manufacturer Interview | WORLDLY

Worldly Industrial is a very well-known Taiwan manufacturer in the flexible packaging industry in Bangladesh. In the interview, Perrys Chang has shared with us how to do business in Bangladesh, we have learnt that the aftercare and maintenance is important as well. She has also shared her observation on the industry after 3 years of pandemic, what policy or changes have Bangladesh made. Let us see the interview to know more about Worldly and how they operate in the flexible packaging market.

G Series Biorenewable TPU Resins | Greco

ISOTHANE® G Series Biorenewable TPU Resins are high performance environment-friendly TPU based on renewable materials with various bio-based content. They exhibit excellent transparency, mechanical properties, abrasive resistance and solvent resistance. ISOTHANE® G series can be processed by extrusion and/or injection molding. #Bio TPU #Bio-based material #recyclable material #Use recycled raw materials #environment #ESG

Co-rotating Twin Screw Extrusion | CYKF

Did you know that?

Because of the low cost and material versatility, strand pelletizing is the most commonly used pelletizing system.

Description:

1. Heating & Cooling System: The material can keep the best temperature in the manufacturing by alternatively using hot water and cold water.

2. Stable Feeding System: The designed screw can avoid material stuck and causing uneven feeding. The feeding quantity can be adusted according to needs.

3. Side Feeder: Used for adding additives including powder, liquid, or pellet type, the side feeder can arrange an automatic system that supplements additives by itself.

4. Vacuum Unit: Purify the pellet by getting rid of exhaust gas or steam from materials.

5. Water Cooling Unit: The water tank cooled the strand plastic, and the organized water tank remains the proper temperature to make the plastic straight and unbroken.

6. Dryer: The dryer removes water from the strand plastic surface with strong wind, and the removed water will return to the water tank eventually.

7. Pelletizer: The pelletizer cut strand plastic into pellets, and the rotate speed can adjust freely, customers can also change other models for bigger productivity.

More product information please visit our website: https://www.cykf.com.tw/tw/product/Strand-Pelletizing-System.html

Campaign Video|EG-8002 Duplex Center Winding Slitter Rewinder|Nicely

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly.

Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

Stand-Up, 3-Side-Seal, Zipper and 4-Border-Seal Bags Making Machine | Dah Bah

Specializes in bag making machine, Dah Bah Machinery Industrial Inc. is the pre-eminent manufacturer of high-quality bag making machine, as well as a complete range of other converting equipment for bag making machine.

All electric blow moulding 20L jerrycan energy saving, no hydraulic oil, no pollution, industry 4.0 | FONG KEE

Model No : FK/EHB-55G-100G-55GT20SD Energy Saving Power consumption 40~50%↓ Production output 20~25%↑

ECO No hydraulic oil, no pollution, Noise level 20dB reduced.

Industry 4.0 Smart manufacturing, with SCADA system.

Corporate Image Video – Plastic Mixing Machine | AVALONG

AVALONG Corporate Image Video – Plastic Mixing Machine, Cold Mixing Machine, Pulveriser System , Automatic Weighing System, Complete Turnkey Plant

AVALONG has been established in Taiwan since 1977. Plastic industry in Taiwan has grown rapidly since then. We design and develop high quality and efficiency High – Speed Mixer, Vertical Cooler, Horizontal Cooler and Semi- Automatic Conveying System suitable for PVC plastic raw materials, chemical materials, cosmetic, food, glass, ferrite, etc.

2024 CHINAPLAS Interview | ChumPower

We are here with Mr. Bush and Mr. Michael from HCI Converting Equipment at the CHINAPLAS. Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries.

Bag Making Automation Solutions at K 2022 | PLAS ALLIANCE

It's such a great honor to interview Eugene Chiu, the Sales Manager from PLAS ALLIANCE LTD.

In the interview, he mentioned influences by the pandemic. In the end, he also talked about the trending topics in recent years, for instance, Circular Economy.

PLAS ALLIANCE LTD. also has excellent customization ability. They provide customized machinery, especially when their customers are searching for Biodegradable Materials applications.

2024 TaipeiPlas International Plastics & Rubber Industry Show| CHUAN LIH FA

At the TaipeiPlas, PRM-Taiwan interviews CHUAN LIH FA MACHINERY WORKS CO., LTD.

In this exclusive feature, CHUAN LIH FA demonstrates their latest custom-designed injection molding machines, highlighting innovations that push the boundaries of technology in the plastic injection molding industry. In this video, you'll learn how their new machines offer significant space-saving designs, as well as the ability to handle multi-color production, making them a versatile solution for manufacturers. Discover how CHUAN LIH FA is not only advancing technology but also fostering talent and driving progress in this dynamic industry.

Find Your Plastic & Rubber Supplier | PRM-TAIWAN

Welcome to PRM-TAIWAN Plastic & Rubber B2B Website introduction video. In this video you will watch how to find Taiwanese Plastic and Rubber Machinery suppliers through PRM-Taiwan.

It's so simple! Just go to www.prm-taiwan.com select the machinery or materials, and send your inquiry. Leave the rest part to us.

Trending in Injection Molding and FCS's Low Carbon Innovation | PIIF

講者: 富強鑫公司 研發處長 林宗彥 博士

《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台

塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

Shredder Integrated Recycling Machine | GEOR-DING-

Shredder Integrated recycling machine Features:

-Can handle large heavy materials or thin-film materials 0:50

-Automatic backfllush screen changer,Reduce the screen changing labor cost 1:03

-Side Feeding Twin Screw design

Screws / Barrels for Extrusion and Injection Molding | NAN YUN

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

Saudi PPPP Through Familiar Eyes: Cosmo’s Perspective on an Evolving Show

Where is Saudi PPPP headed?

In this on-site interview, Cosmo shares insights from years of participation, noting subtle shifts—like fewer machines on display. More significantly, Messe Düsseldorf’s quiet partnership hints at deeper changes in the region’s manufacturing and exhibition landscape

Bio TPU Resins | GRECO

ISOTHANE Bio TPU

Sustainable bioplastics derived from natural plants, Make life more energy efficient and make the world a better place to live.

Hydraulic Slitter and Cutting Machine | Yicheen

Hydraulic Slitter and Cutting Machine

Zipper Bag Making Machine | WORLD STEEL

World Steel-Zipper Bag Making Machine

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

2023 Plast Eurasia Interview | WEI MENG

It's our great honor to interview WEI MENG and their Turkish agent in the 2023 PlastEurasia.

Watch our video for more information!

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES:

1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions.

2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation.

3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.

4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items.

5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects.

6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

2024 CHINAPLAS Interview | ABIMAQ SINDIMAQ

It’s our great honor to interview Mr. Marcelo Zimmaro, Machinery and Accessories Sectorial Chamber for the Plastic Industry from ABIMAQ SINDIMAQ Brazil. In this interview, Jason asked him about ABIMAQ's services and business scope, his views on the economic situation in Latin America in recent years, and his expectations for this exhibition in China. Mr. Marcelo Zimmaro stated that their mission at the exhibition is to assist the Brazilian machinery industry in import and export activities, and they hope to find more allies and friends at this exhibition. For more detailed interview content, please stay tuned for the upcoming PRM reports. PRM is committed to collaborating with global media to bring more information about the world's plastics and rubber industry to everyone.

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Pet Waste Bag With Label Perforating Bag On Roll Making Machine- BJAHC1+CFS | PARKINS

Model: BJAHC1+CFS

Demonstration size: 20”

Remarks: Designed for production efficiency and precision, this machine integrates advanced automation technology, enabling stable production at high speeds while ensuring accurate label placement on every bag. With a user-friendly interface, it is easy to operate and has low maintenance costs, making it an excellent choice for businesses requiring mass production of eco-friendly bags or garbage bags. This model can be customized to meet various needs, catering to the diverse application scenarios of our clients. For further information, please don't hesitate to get in touch with us.

2024 CHINAPLAS Interview | BoReTech

We are here with Mr.Alan Ou from ZHEJIANG BORETECH ENVIRONMENTAL ENGINEERING CO., LTD. at the CHINAPLAS. BoReTech is a leading company in the plastic recycling industry, that strives to solve plastic waste and give it a second life. With more than 30 years of experience in the industry, BoReTech can process different materials from different countries and gain know-how experience.

Sustainable Polymer Solutions | PIIF

講者: 錦欣貿易(股)公司 李明曄 經理

《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台

塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

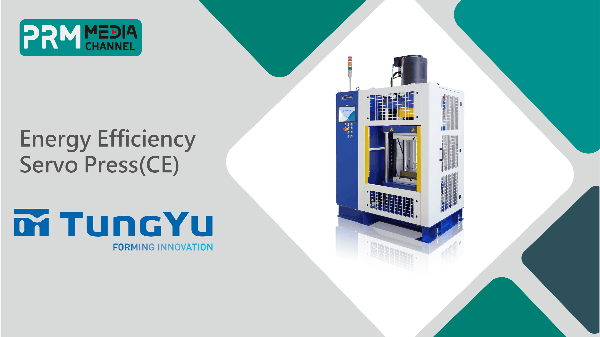

TungYu Energy Efficiency Servo Press(CE) | Tung Yu

⚫Servo motor drive:Servo press use servo motor as the power source, with transmission mechanism and pressure sensing element to provide the required power for the press, and link the guide screw straight joint press head (or center base) to directly provide the required load for the workpiece.

⚫Planetary roller screw:Planetary screw uses a roller instead of a ball between the screw and the nut to greatly improve the rigidity and increase the contact area. The roller rotates around the screw in the same way as the earth orbits the sun, and the loading capacity is three times that of a ball screw, which improves stability and thus extends the life of the screw.

⚫Independent heating platen temperature control system:Provide preheating function before the mold waiting for hot press molding, shorten the hot press molding time and improve the production efficiency.

⚫Energy saving and environment cleaning:The power consumption rate of the servo motor is more economical than traditional motor with pump design.Without hydraulic system there is no oil leakage and low maintenance.It is suitable for working environments with low pollutions, such as electronics industry, biotechnology industry, etc.

⚫Precise movement:Control parameters can be input from HMI, and action commands can be issued to driver through PLC and implement servo motor actuation to achieve high-precision control on working force, speed or position performance. The servo motor is directly connected to the lead screw head (or moveable traverse) through the transmission to have direct required load.The features are to precisely provide key parameters of working force, speed and position in production.

⚫Complete process setting function:It is convenient for the user to set up process parameters and save portable files as backup.

⚫Convenient data tracking and statistical result output:The data and graphs of each cycle could be presented as batch statistical information for tracking by operator easily.

⚫Real-time monitoring of press status:Display of cycle graph and monitoring of press status, sensors and statistics. Real-time production information such as quantity and yield rate to improve the control efficiency and accuracy.

Aluminum Foil Printing Techniques | WORLDLY

Have you ever wondered how essential it is for manufacturers and consumers to have the right packaging or sealing material on a decomposable product like medicine, snacks/drinks, or any other related product?

By interviewing Klive from WORLDY, we have been explaining what kind of technical strengths Worldly has and they are capable of manufacturing and designing customization machines according to client's demand. Moreover, You will obtain the knowledge of the difference between plastic and aluminum foil to understand the applications of each materials.

Sheet Cutting Machine | YICHEEN

Description:

Friendly interface, PLC computer touch-panel screen control system.

Non-hydraulic design, no pollution, low noise, best for using in dustless room.

Servo motor control feeding (for EVA sheet cutting tolerance +/-1mm).

Modulating control for tension control, it keeps cutting stable.

Anti-static PU roller drive for reducing scrape happened.

Optional devices: Shaftless unwind stand (electrical left/right moving), EPC (Edge Position Controller), Slitter, Punching device (electrical left/right moving), Automatic stacker, Static eliminating device,

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W

For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

2024 TaipeiPlas International Plastics & Rubber Industry Show| TienKang

In this exclusive interview at TaipeiPlas, I meeting with Daniel from Tien Kang to discuss their groundbreaking new technology that utilizes 100% recyclable pellets. Daniel also shares insights into the various materials they use, including EVA, SEBS, TPU, TPEE, and PEBAX, to create the perfect in midsoles and outsoles . Watch to learn more about how Tien Kang is pushing the boundaries of innovation in sustainable footwear production! #TaipeiPlas #TienKang #SustainableTechnology #RecyclablePellets #Insoles #FootwearInnovation

2024 NPE Interview | NPE The Plastics Show

We at NPE invited PLASTICS Marketing Director Damaris to be interviewed by us. Sharing the latest news at the 2024NPE exhibition, there were 50,000 visitors on the third day of the exhibition. This is something very happy about.

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

2023 IPF Interview | BPGMEA

It is our great honor to have the opportunity to interview Mr. Shamim Ahmed, the president of BPGMEA (Bangladesh Plastic Goods Manufacturers & Exporters Association). In the interview, Mr. Shamim shared much information about the plastic, printing and packaging industry, IPF Bangladesh is rapidly growing and gaining more exhibitors and visitors every year.

台北包裝展 2023 | PRM 帶看展

TAIPEIPACK 台北包裝展|PRM-TAIWAN

萬眾矚目的台北包裝展來囉!

無法來現場參與的夥伴們,別擔心! PRM這次也為大家準備了帶看展的節目 帶大家一睹展場的熱鬧氛圍!