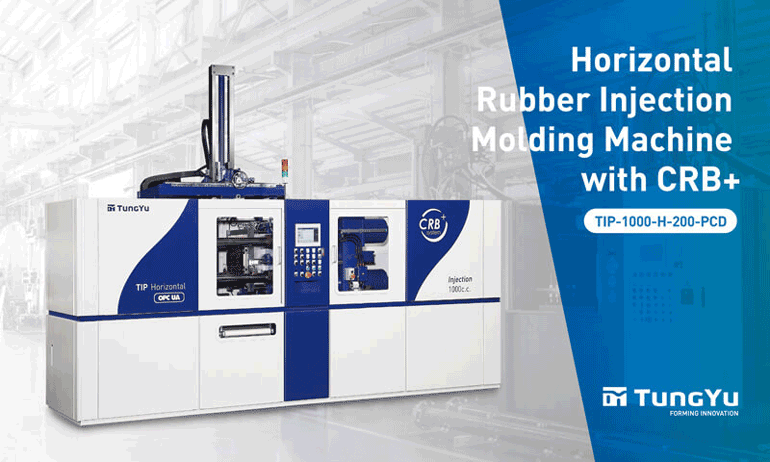

TungYu: Horizontal Rubber Injection Molding Machine

How to save material and increase productivity simultaneously?

Horizontal rubber injection molding machines can contribute to reducing material waste and optimizing automation.

Tung Yu makes our effort to serve the best solution for customers.

Mechanical feature at a glance-

- Horizontal structure with ergonomic design.

- Low machine working height can be more flexible for mold opening stroke, also benefits material feeding, inspection and maintenance.

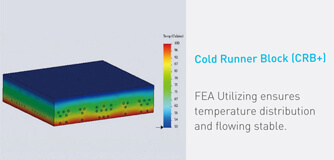

- With the Cold Runner Block (CRB+) control system can high utilization materials by reducing waste and saving production costs.

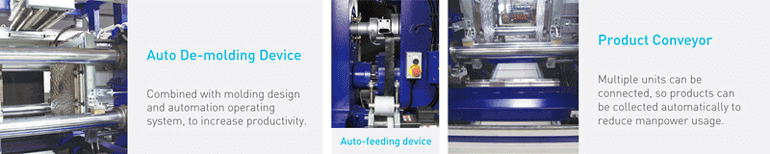

- Equipped with auto de-molding device for finished products can be dropped by its own weight, and improve auto production process.

- Compiled with OPC UA standard, seamlessly integrate other molding equipment and peripheral systems.

- To have a precise injection volume with FIFO injection design.

- Multiple units can be connected, so products can be collected automatically to reduce manpower usage.

Cold Runner Block (CRB+)- Brand new patent from TungYu Innovation Center

Thermostatic control module for the runner block keeps the compound under a constant of target temperature precisely, meanwhile, let compound smoothly flow and maintain the normal properties of compound. We also have several shut off valves to control the flow route of compound, and the customers can feel free to choose which nozzle they want to use.

Developed by Tung Yu, the CRB+ system could be regarded as a subsystem and be conveniently attached to the any injection machine. It is no longer to customize the CRB limited by the mold features.

Developed by Tung Yu, the CRB+ system could be regarded as a subsystem and be conveniently attached to the any injection machine. It is no longer to customize the CRB limited by the mold features.

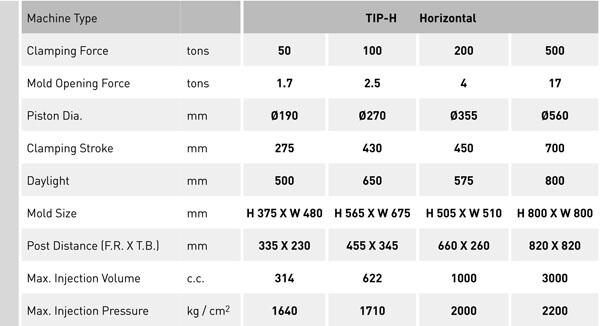

Technical Specifications

Remarks

1.Min. injection volume can be 5 c.c.

2.Clamping force and injection volume can be designed according to different requirement.

3.Injection pressure between the range is regular design and wecan support the others out of this range for optional.

1.Min. injection volume can be 5 c.c.

2.Clamping force and injection volume can be designed according to different requirement.

3.Injection pressure between the range is regular design and wecan support the others out of this range for optional.

TungYu Official Website:

https://www.tungyu.com/

TungYu at PRM-TAIWAN:

https://www.prm-taiwan.com/com/tungyu.html

E-News Categories

押出機および押出全体のプラント設備

- バブルマット製造装置

- 布押出バブル押出ライン

- 共押出バブル布の生産ライン

- 機器のバッグ

- フィルム吹いマシン

- フィルム吹いマシン

- フィルム吹いマシン

- キャストフィルム機

- コーティングマシン

- EPS / EPE発泡シート押出

- 押出機

- 積層機

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- モノフィラメント押出機

- モノフィラメント押出機

- PET Strapping Band Extrusion Lines

- マシンを作ります

- プラスチックフィルムの共押出

- プラスチックパイプ製造機

- プラスチックパイプ製造機

- PVCホースマシン

- ストロー製造機

- 二軸スクリュー押出機

- 二軸スクリュー押出機

- バッグマシン