GMA Machinery's Evolution from Extrusion die Craftsmanship to Slot Die and Coating Equipment - A Journey of Unwavering Excellence

For over 30 years, GMA Machinery, with its rich experience in extrusion die design and manufacturing, has caught the attention of global extrusion machine market. What prompted GMA Machinery to smooth transition from specialized extrusion die design and manufacturing to enter the slot die and coating equipment and equipment sector? How did it swiftly emerge as the new choice for slot die and coating equipment in the optoelectronics and precision manufacturing industries?

Precipitation, Accumulation, Cultivation, Persistence—GMA Machinery's coating technology is surging in the new energy market!

Most commonly, coating applications are associated with industrial painting and wood/metal processing, predominantly within the plastics and rubber industries. These include applications in the printing and packaging sectors, involving coatings on films, sheets, paper, or packaging materials. However, in recent years, with the rapid emergence of the new energy market, the application of coating technology has increasingly shifted towards high-tech and high-precision domains, demanding heightened accuracy and attention to detail in coating.

Coating technology has found extensive applications in the new energy market and the optoelectronics industry. GMA Machinery, traditionally focused on extrusion die heads and related components, has quietly gained ground in the coating market of this industry, becoming a new favorite choice for numerous domestic and international high-tech manufacturers."

PRM recently visited GMA Machinery located in Wuchi, Taichung, focusing on the design and manufacturing of dies, feed block and screen changer for extrusion lines. Their application of coating technology includes coating machines and slot dies.

The most crucial aspect of the coating process is uniformity and stability, requiring precise application of optical or various materials onto flat or curved surfaces. The pivotal element in this process is the slot die. GMA's slot dies are designed with channel layouts based on the characteristics of the materials. Moreover, they can be paired with automatic controllers for highly accurate adjustments, showcasing GMA's mastery and familiarity with various material properties. Their adept utilization of advanced channel simulation analysis technology in the R&D department, coupled with extensive design and production experience, allows them to grasp the key of design and processing.

Designing during research and development is only the first step; achieving dies as refined as craftsmanship demands meticulous on-site processing techniques. GMA Machinery spared no expense in introducing multiple flat grinding and drilling equipment, positioning themselves as leaders in the industry. "In fact, over a decade ago, GMA Machinery systematically familiarized itself with the structure and production essentials of slot die and coating equipment to effectively address customers' coating needs and issues," shared Founder Jessie Hsu, who initially envisioned the investment with great vision. Today, General Manager Howard Chao, along with Manager Eric Hu, possessing rich coating process experience, collaborates with the team to progress continuously. They have transitioned gradually from slot dies into the design and production of coating machines. Manager Hu noted, "Quality control in coating during practical experience isn't solely about slot dies; it's deeply interrelated with the entire coating technology and equipment. To solve customer problems and elevate our technology, as a result of our continuous efforts, we've developed a coating machine—everything will fall into place.

Driven by a deep sense of responsibility towards customers and a commitment to uncovering core issues, persistent dedication and gradual accumulation have propelled recognition in the coatings field today.

GMA Machinery's new patch coater immediately captured market attention upon its launch

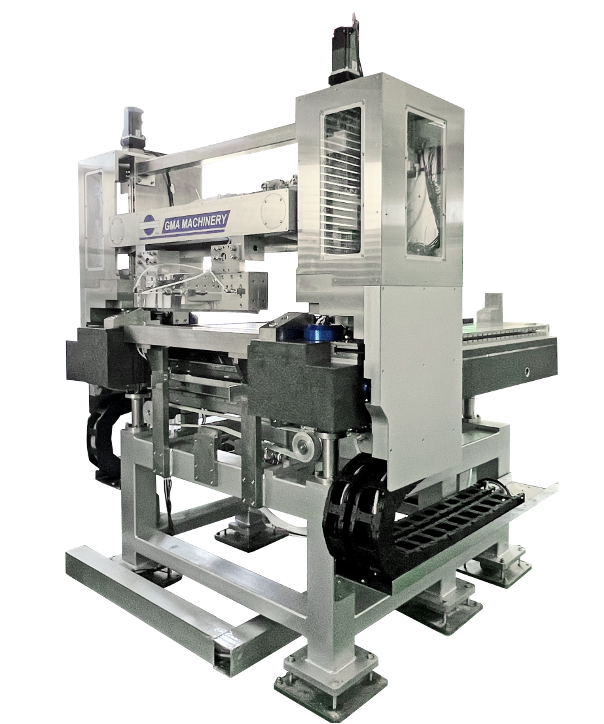

GMA Machinery acknowledges the global potential in coating machine development. They provide R2R pilot machine and slit coater (A4 size) machines, alongside the specialized design of the patch coater such like TAB2001 specifically crafted for the new energy.

As above: Patch coater (TAB2001), primarily utilized for the coating process on flat substrates.

This patch coater machine is primarily used for the wet coating process on flat substrates, widely applicable in industries such as flat panel display manufacturing, touch panel production, backlight modules, transparent conductive substrates, and solar energy processes.

GMA's TAB2001 can coat various materials, including photoresists, conductive polymers, hardened coatings, optical adhesives, and copper indium gallium oxide slurries, providing comprehensive support for customer innovation in the new energy market. The machine features an advanced glue supply system, precise slit dies, vacuum platforms, and an air flotation control system, ensuring stable pressure during coating and consistent coating quality.

Additionally, the intelligent design of the electronic control and operating systems provides a more convenient and efficient operational method, aiding customers in achieving production automation and enhancing production efficiency. Utilizing granite vacuum platforms, air flotation control systems, and a loading and unloading ejector system improves coating smoothness and stability, providing customers with higher production efficiency and precision.

Image: Sealed pumping system, ensuring stable pressure and conserving coating materials.

Image: Our self-developed slot die featuring a Lip Self-Cleaning System, achieving replication accuracy within 2 microns.

Image: Equipped with VNC Server Remote Access System.

Developing specialized laboratories for customers to swiftly resolve issues and gather valuable coating-specific data.

After understanding the excellent performance of GMA's flat coating machine, the PRM journalist was curious about the key factors that allowed GMA to quickly grasp the development of slot dies and coating equipment, assisting customers in solving various complex issues. The head of the research and development department smiled and said, "This is thanks to our establishment of a coating laboratory for customers. Initially, it aimed to improve the quality of slot dies and locate uneven coating issues. Hence, the company invested substantially in an experimental machine. Later on, many customers inquired about testing materials, gradually transforming it into a professional laboratory."

Unexpectedly, this move received positive responses from many customers. It turns out there are numerous theoretical ideas in developing coating technology that need practical implementation for verification and exploration of solutions. Through discussions with customers over time, they gradually accumulated professional data and experience in coating equipment, all of which became nutrients for GMA's research and development innovation.

In a fiercely competitive market environment, the speed and efficiency of research and development are crucial for a company's success. GMA Machinery's specialized coating laboratory, equipped with various coating machinery, plays a pivotal role in assisting clients in swiftly translating innovative concepts into tangible, practical products.

So far, GMA Machinery has assisted numerous domestic and international clients in developing new products, refining existing processes, evaluating modifications, and procuring equipment. Each week, various company research and development engineers schedule experiments, showcasing GMA's expert technical team, versatile coating experimental lines, and laboratories. These not only facilitate clients in new product development and process optimization but also offer professional advice and solutions, ensuring product quality and performance. With decades of honed expertise in coating technology, GMA remains committed to partnering with clients, nurturing a collective aspiration for continuous innovation and remarkable advancements in multiple coating techniques.

Image: GMA Machinery not only offers equipment rental services but also provides expert guidance from an experienced team.

As I stepped out of GMA Machinery, it struck me that success is never an overnight feat. GMA's journey from extrusion die to slot die and coating equipment, then venturing into the realms of optoelectronics and new energy, reflects years of relentless dedication to refining coating technology.

Taiwan's standing in the global market owes much to unsung heroes like GMA Machinery—steadfast in their original vision, silently persevering, and wholeheartedly advancing. What groundbreaking innovations await GMA next? That's something to eagerly anticipate!