PARKER: Review the Benefits of NPE 2024

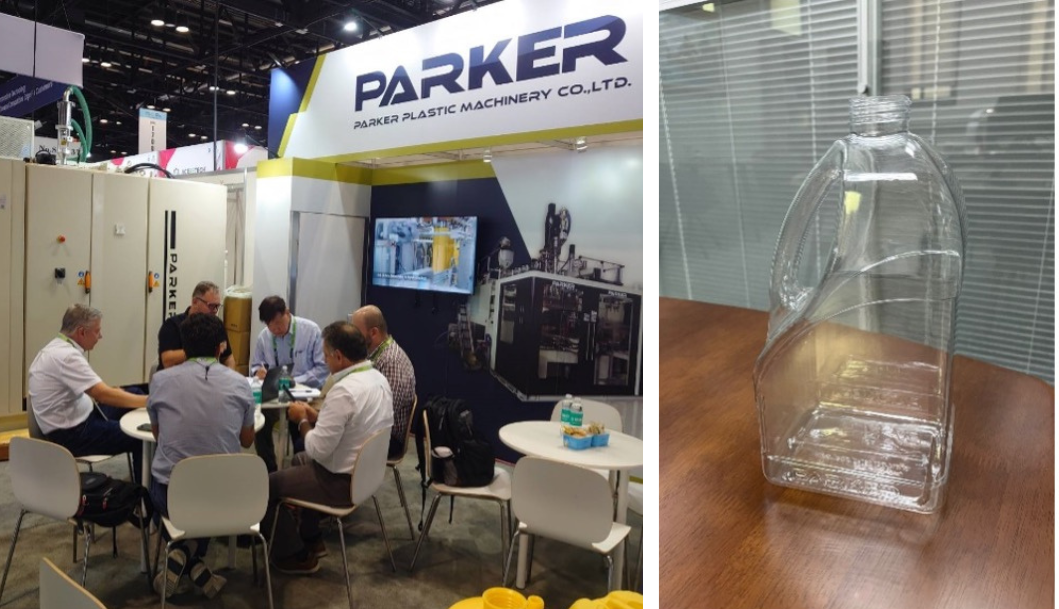

This is the fourth time that PARKER PLASTIC MACHINERY CO., LTD. has participated in NPE, our booth located at South Hall, and our booth number is S15129. The display machine model is all-electric extrusion blow molding machine with the latest successfully developed extrusion grade PET plastic raw material.

This display machine is full electric single station single head blow molding machine, the bottle maximum size is up to 5L and SIEMENS control system is used in this machine. This display machine is the latest design die head & screw for new extrusion PET material. The mold trial sample is 2.5L PET bottle with handle. The advantage of extrusion PET material is that container with handle can be blew at once. Unlike common grade PET material which handles can only be added or insert after the production.

Blowing at once by using the same material is definitely more economic, time-saving and easily recycled. And, we deeply believed that this innovative material definitely can replace current added or insert handle PET bottle market easily.

Actually, this exhibition successfully attracted crowds of people, especially the PET bottle manufacturers, they are get highly interested with this new material which can blew the handle at once. We are looking forward to and believe that they will become our new customers in the near future.

In the plastic machinery industry, NPE is one of the most important exhibitions. The visitors are mainly potential customers from Americas regions. This professional exhibition provides a very good venue for machine manufacturers to find potential customers, dealing with old customers, and also allows customers to easily compare and find machines that meet their expectations in a short period of time.

|

|

|

Therefore, participating in this exhibition is very beneficial. Through this exhibition, we have also successfully received some orders. Beside the new machine for extrusion blow PET material, Parker's major machines mainly for extrusion grade PE, PP, PVC, PETG materials. We have all-electric type, hybrid type, hydraulic type and pneumatic type blow molding machine, and the product volume from 20ml to 220L. Full electric type if compare with hydraulic type blow molding machine, the advantage is that it can save electric power for up to 30~40%, and the productivity rate will increase up to 20~25%. Base on the project size and future growth, such as the monthly demand on each bottle size, we can recommend the right machine model. For big project but small container size, we have double station and up to 8 die head machine. For big drum from 30L to 220L, we have different size of accumulative type blow molding machine.

To protect the environment, and reduce the material cost, we have multi-layers models which can use recycle material for up to 60~80% on inner or center layer, and which left 20~40% of virgin material used.

PARKER is one of the well-known brands in the blow molding machine industry, and we are from Taiwan. If you have any new projects and need us to recommend machines, please feel free to contact us.

PARKER PLASTIC MACHINERY CO., LTD.

No. 6, Aly. 26, Ln. 198, Minsheng Road,

Wufeng Dist., Taichung City 413,

Taiwan.

Tel: +886 4 2339 6828

E-mail: [email protected]

Website: www.parker-global.com

押出機および押出全体のプラント設備

- バブルマット製造装置

- 布押出バブル押出ライン

- 共押出バブル布の生産ライン

- 機器のバッグ

- フィルム吹いマシン

- フィルム吹いマシン

- フィルム吹いマシン

- キャストフィルム機

- コーティングマシン

- EPS / EPE発泡シート押出

- 押出機

- 積層機

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- モノフィラメント押出機

- モノフィラメント押出機

- PET Strapping Band Extrusion Lines

- マシンを作ります

- プラスチックフィルムの共押出

- プラスチックパイプ製造機

- プラスチックパイプ製造機

- PVCホースマシン

- ストロー製造機

- 二軸スクリュー押出機

- 二軸スクリュー押出機

- バッグマシン