How to Choose the Right Garbage Bag Manufacturing Machine to Boost Efficiency and Profitability?

If you're considering purchasing a garbage bag manufacturing machine, you're likely seeking equipment that enhances production efficiency, improves product quality, and ultimately boosts your profitability. Selecting the right machinery that meets your production needs is essential, and we are here to guide you through this process.

In this article, we will discuss various types of garbage bag machines available on the market, highlight their key features, and outline the practical business advantages they offer. By the end of this guide, you'll clearly understand how to choose the best equipment tailored to your production requirements and how to maximize your investment returns.

For those interested in broader bag production options, don’t miss our Comprehensive Guide to Plastic Shopping Bag Making Machine, which covers the specific details on plastic shopping bag production.

|

|

|

How Garbage Bag Making Machines Operate

In essence, garbage bag making machines are designed to streamline the manufacturing process. You begin by feeding plastic film rolls—typically made of polyethylene—into the machine. The machine melts the film into a continuous sheet, which is then cut to your desired specifications using heat-sealing technology to ensure strong seams. Whether you need handles, perforations, or drawstrings, these machines offer customization options to tailor your products. Once completed, the finished bags are either stacked or rolled, ready for packaging and distribution. If your focus is on producing garbage bag rolls or bin bags, these machines are built to handle high-volume production while maintaining consistency.

Types of Garbage Bag Making Machines

Here’s an overview of the most common types of garbage bag making machines:

-

Bottom Sealing Garbage Bag Making Machine: Perfect for creating flat, sturdy bags. This machine processes single or double layers of film and seals the bottom for added strength.

-

T-Shirt Bag Making Machine: These machines produce the popular t-shirt style garbage bags with handles, commonly used in grocery stores or for high-volume purposes.

-

Star Sealing Garbage Bag Making Machine: Known for creating star-sealed bags that distribute weight evenly, these are excellent for heavy-duty applications.

-

Perforated Roll Garbage Bag Making Machine: Produces perforated bags on rolls, perfect for easy dispensing. Think of the garbage bags you tear off in public bins or for household use—this machine handles that production seamlessly.

-

Drawstring Garbage Bag Making Machine: If you need bags with drawstrings, these machines are designed to produce them, offering convenience for consumers and suitability for both household and commercial applications.

For those focused on sustainability, a Biodegradable Garbage Bag Making Machine allows you to produce eco-friendly bags that meet the growing demand for sustainable products. Investing in a biodegradable garbage bag manufacturing machine will help you stay competitive in a market that values environmentally responsible solutions.

What to Look for in a Garbage Bag Making Machine

When buying a garbage bag manufacturing machine, here’s what matters most:

-

Production Speed: A faster machine means higher output. If you're in high-volume production, look for machines with adjustable speeds to keep things flexible.

-

Bag Width and Thickness Range: A versatile machine that can handle various bag sizes and thicknesses will meet different customer demands. Whether it’s trash bags, refuse bags, or standard garbage bags, this flexibility is key.

-

Energy Efficiency: Machines with energy-saving features can lower your operational costs, making a big difference in the long run.

-

Ease of Operation and Maintenance: You want a machine that’s easy to operate and maintain. Automated maintenance alerts or simple control panels can save you downtime and hassle.

Why Upgrading to a Modern Garbage Bag Machine Makes Sense

If you’re still using older equipment, upgrading to a modern garbage bag making machine brings clear benefits:

-

More Automation: Modern machines do more of the work for you. Less manual input means fewer errors, faster production, and lower labor costs.

-

Better Customization: You can control every detail, from bag size to sealing strength, ensuring each bag meets your customers' exact needs.

-

Cost Savings: The upfront garbage bag machine price might seem high, but with lower energy consumption and reduced maintenance, you’ll save money over time.

-

Durability: Today’s machines are built to last longer, reducing the need for constant repairs and replacements, protecting your investment.

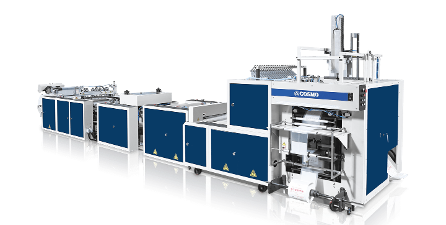

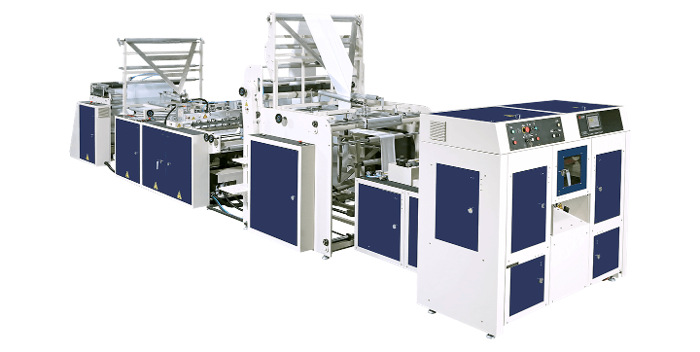

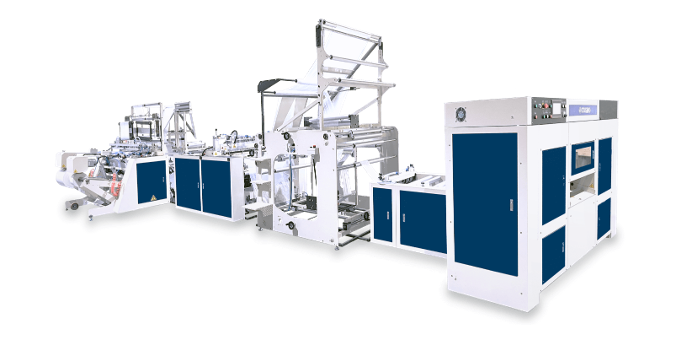

Cosmo Machinery’s Solutions for Your Garbage Bag Production

Finding the right machine to fit your production needs is crucial. Cosmo Machinery offers a variety of plastic garbage bag making machines designed to handle different sealing methods, production options, and automation levels. Here’s a look at some of our top machines:

This machine is all about precision and speed. With servo motor technology, it lets you produce S-shaped perforated coreless garbage bags with high accuracy, reducing labor costs and boosting output.

If adaptability is key for you, the Coreless Garbage Bags-On-Roll Making Machine features a 4-shaft rewinder system, making it perfect for switching between different bag sizes and thicknesses. High output, low hassle.

Looking to diversify your product line? The SBCR 750 OB produces various types of bags on rolls, with fast operation and consistent quality, ideal for trash bag making or refuse bag making.

This machine uses an innovative V-C-N shape folding system to create coreless garbage bags in sheet form. Great for food service or waste management industries.

Need a machine that can do both core and coreless bags? This versatile option is compact and efficient, making it perfect for facilities with limited space but high production demands.

Key Features of Cosmo's Bag-on-Roll Machines

Here’s what sets Cosmo Machinery’s Bag-on-Roll machines apart:

-

High-Speed Production: Machines like the SR-40/SR-50 High-Speed Coreless Star Seal Bag on Roll Machine can produce up to two lines at once, increasing your production speed exponentially.

-

Coreless and Core Bag Options: Reduce waste with coreless bags or use core bags for easy retail dispensing—our machines handle both.

-

Star Seal and Bottom Seal Capabilities: Whether you need strong star seals for heavy-duty applications or bottom seals for lightweight bags, Cosmo has the machine for you.

-

Automatic Perforation and Roll Changing: No more interruptions—automatic perforation and roll-changing features keep production flowing smoothly.

-

Multi-Layer Material Compatibility: Whether you’re working with HDPE, LDPE, or multi-layer films, Cosmo’s machines can handle it all.

Success Story: U.S. Client Launches New Manufacturing Facility in Vietnam

A U.S.-based plastic bag manufacturer, looking to boost its production capacity and broaden its sales reach, embarked on an exciting expansion by setting up a new manufacturing facility overseas. After carefully evaluating options, they decided to establish this new factory in Vietnam, driven by their solid trade relationships and favorable business environment within Vietnam's thriving plastics industry.

To ensure a seamless and efficient launch, the client required reliable, high-capacity plastic bag-making machines to support the factory’s early operations. Given the geographical proximity and ease of transportation between Taiwan and Vietnam, along with the ability to deliver swiftly and provide technical support, they chose COSMO for their initial order of plastic bag-making equipment.

COSMO stepped in and promptly fulfilled a substantial order, supplying the client with the necessary machines within a few months. Thanks to this collaboration, the U.S. client’s new overseas factory is now fully functional and operating at peak capacity, marking a successful start to their expansion efforts in Vietnam.

Why Choose Cosmo Machinery?

When selecting a garbage bag manufacturing machine, experience is key. With over 35 years in the industry, Cosmo Machinery provides dependable, high-performance equipment tailored to your unique requirements. Our emphasis on automation, efficiency, and customization ensures you remain competitive while upholding sustainability.

Key Benefits of Choosing Cosmo Machinery:

-

High-Speed Production: Equip your large-scale operations with machines like the SR-40/SR-50 High-Speed Coreless Star Seal Bag on Roll Machine, designed for maximum output and reliability.

-

Coreless and Core Bag Options: Select from coreless bags to minimize waste or core bags for convenient retail applications, offering flexibility based on your production needs.

-

Star Seal and Bottom Seal Capabilities: Whether you need star sealing for even weight distribution or bottom sealing for added strength, our machines accommodate all your sealing requirements.

-

Automatic Perforation and Roll Changing: Maintain uninterrupted production flow with our automatic roll-changing systems, enhancing efficiency and reducing downtime.

-

Customizable Settings: Easily adjust bag length, thickness, and sealing options to match your specific production specifications, ensuring your products meet exact standards.

Ready to elevate your manufacturing process? Contact Cosmo Machinery today to discover how our cutting-edge technology can enhance your production efficiency and drive your business forward.

|

|

|

Related Article: