Video Description

Did you know that?

Because of the low cost and material versatility, strand pelletizing is the most commonly used pelletizing system.

Description:

1. Heating & Cooling System: The material can keep the best temperature in the manufacturing by alternatively using hot water and cold water.

2. Stable Feeding System: The designed screw can avoid material stuck and causing uneven feeding. The feeding quantity can be adusted according to needs.

3. Side Feeder: Used for adding additives including powder, liquid, or pellet type, the side feeder can arrange an automatic system that supplements additives by itself.

4. Vacuum Unit: Purify the pellet by getting rid of exhaust gas or steam from materials.

5. Water Cooling Unit: The water tank cooled the strand plastic, and the organized water tank remains the proper temperature to make the plastic straight and unbroken.

6. Dryer: The dryer removes water from the strand plastic surface with strong wind, and the removed water will return to the water tank eventually.

7. Pelletizer: The pelletizer cut strand plastic into pellets, and the rotate speed can adjust freely, customers can also change other models for bigger productivity.

More product information please visit our website: https://www.cykf.com.tw/tw/product/Strand-Pelletizing-System.html

-

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

-

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

-

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

-

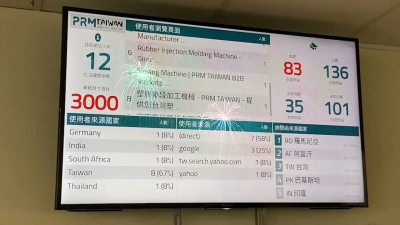

Thanks to 3000+ Members of PRM-TAIWAN B2B Platform

Thanks to 3000+ Members of PRM-TAIWAN B2B Platform

-

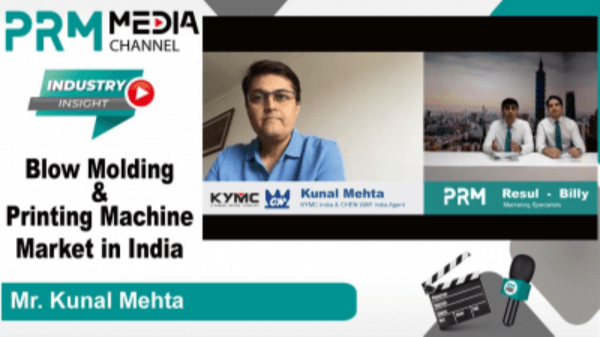

Industry Insight: Blow Molding Machine and Printing Machine Market India

Industry Insight: Blow Molding Machine and Printing Machine Market India