Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

ALL STYLES

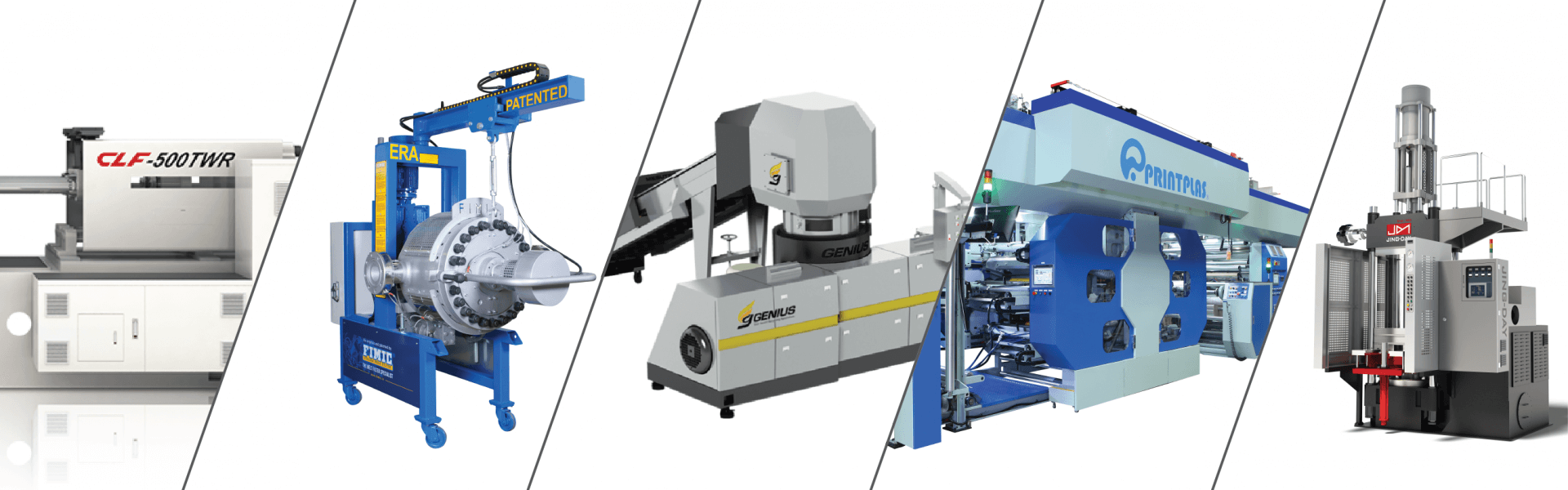

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine

00:00 Opening

00:08 Blown Film

00:28 Machine current speed

00:37 Cutting, Sealing & Punching

00:54 Sending finished bag to Carton Packaging Section

01:07 Take-up Tower & Printing

02:27 Carton Packaging Proccess

05:04 Ending

---

Website : www.jandis.com.tw & www.inflationmachine.com

Facebook : www.facebook.com/JANDIS.JIT

Email : [email protected]

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

SING SIANG MACHINERY CO., LTD

The machine is applied for solvent-based ink and direct printing method for woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min and “New Type” Auto. Roller Exchanging System for Un-winder & Re-winder.

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry.

*Contact Info:

Web: https://www.everplast.com.tw/

Facebook: https://reurl.cc/r1LZb

YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg

1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/

2.https://www.everplast.com.tw/product/machine-line/

3.https://reurl.cc/QeMrp0

Tel: +886-2-2289-7271 / +886-6-201-4846

Fax: +886-2-2289-7282 / +886-6-201-4290

Email: [email protected]

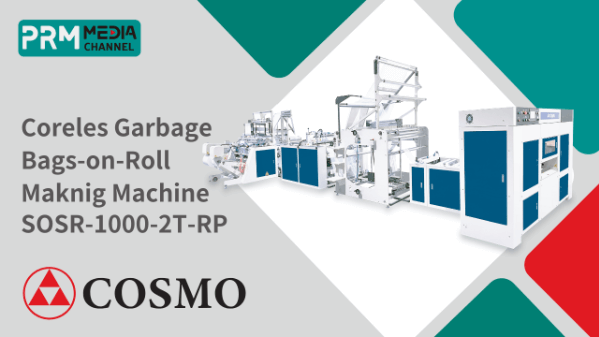

Flexible production with star sealing and bottom sealing.

Shuttle system & 4 shafts re-wind system for stability and high out put.

Servo driven system for high production capacity.

From film roll to finished bag roll, computer control over the entire process.

It's easy to adjust the bag length, film tension, and production speed on touch screen.

Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed.

Auto reel changing device and bag pull off device on re-winder.

Automatically stop on miss-color scanning / film breaking / running out of film.

MODEL

SR(2)MR(1)-1000-OS-2T-R4S

Bag Length

350 - 1500 mm

Finished Product

Ø150 x 600 mm (single line)

Ø150 x 250 mm (2 lines)

Film Thickness

0.008 - 0.060 mm / layer (bottom seal)

0.008 - 0.035 mm / layer (star seal)

Film Roll Size

Ø1000 x 900 mm (single roll for bottom sealing)

Ø1000 x 500 mm (2 rolls for star sealing)

Production Speed

150 meter / min / line (max)

Power

220V, 3Phases, 50/60HZ, 30KVA

Heater

6.2 KW

Required Air Compressor

6HP (not included)

Dimension

L10000 x W2600 x H2500 mm

* 規格如有變更改進,恕不另行通知。

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets.

This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system.

If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business.

Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making.

This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

PARKER PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine

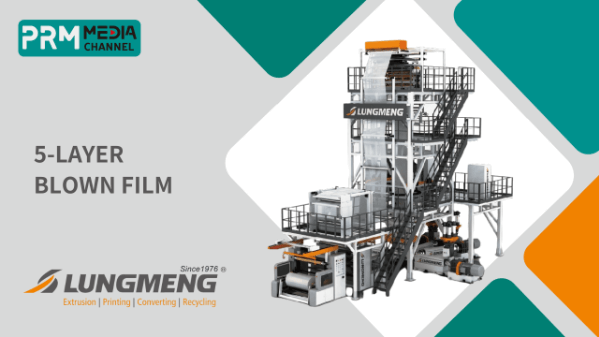

PIRANHA-45, Mini recycling machine | Lung Meng

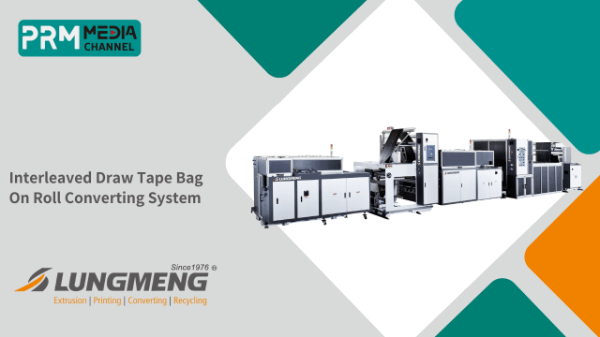

TA-IPD-XL-Q series. Public version, CE Version. Double sealing /Double perforation /Interleaved 2 in 1 rewinder. in-line labeling machine