Recent Fair Shows

Passionate for International Exhibitions? PMC takes you to another level to experience it. Stay tuned!

Hello everyone! It's been a long time since last CHINAPLAS Let one of partner from PRM—— Joey Show you all the fantastic things at CHINAPLAS Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

What! You don't know which manufacturers are participating CHINAPLAS? Hurry up and check out the CHINAPLAS on-site tour brought to you by PRM.

Let Alice show everyone the charm of the CHINAPLAS. Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

->PRM booth number: 7G01

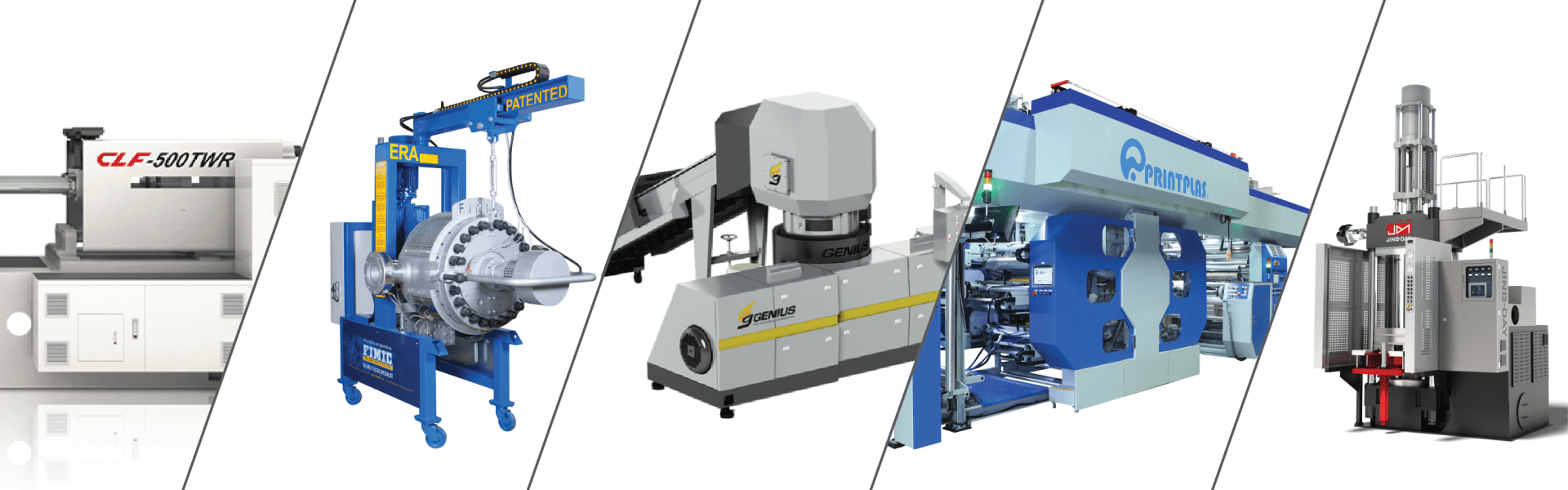

CHINAPLAS 2023 The 35th International Exhibition on Plastics and Rubber Industries

Date: 2023.4.17-20

Opening Hours: 09:30-17:00

Venue: Shenzhen World Exhibition & Convention Center (No.1 Zhancheng Road, Fuhai Street, Bao’an District, Shenzhen, Guangdong, PR China)

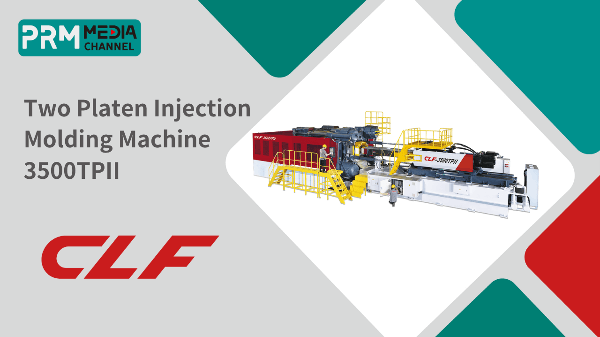

➡️ Maximum injection weight 34 KG.

➡️ High stability, High efficiency, High energy saving..

➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy.

➡️ Direct pressure clamping to make the mold evenly stressed.

➡️ Smooth, stable and powerful.

➡️ Uniform tension force on tie bars for dramatic increase of service life.

➡️ Simplified construction with no wearing problem on toggle clamp.

Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

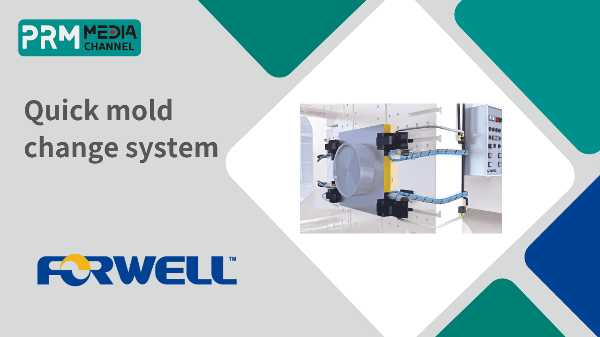

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety.

Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits.

Indirect Benefits

Die Standardization

Press Standardization

Increased Safety

Improved Working Environment

Increased Competitiveness

Direct Benefits

Reduction in Die Change Time

Efficient Small Batch Runs

Reduced Stock Handling

Higher Productivity and Quality

Reduction in Labor Costs