2023 IPF On-site Tour | PRM

IPF Bangladesh 2023 Bangladesh Exhibition covers "three main industries", including plastics, packaging and printing industries, creating opportunities for buyers and manufacturers to communicate with each other! Let PRM Alice show you the IPF Bangladesh 2023 exhibition!

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

CHINAPLAS 2021 | PRM What to Say EP1

PRM Media Channel is here with a brand new program: PRM What to Say. More Info: https://bit.ly/2RngTZM Due to the rapid transformation in many industries because of pandemic, including plastics and rubber industry, we all realized the power of social media and video marketing. Through PRM What to Say program hosted by PRM Media Channel, we aimed to bring current issues of plastics and rubber industry on the table, and discuss these topics with experts and listen the possible solutions. Let's take a look at our first episode about CHINAPLAS 2021 and let us know your opinions and questions in the comments section. Thank you for your support!~

2024 CHINAPLAS Interview | ABIMAQ SINDIMAQ

It’s our great honor to interview Mr. Marcelo Zimmaro, Machinery and Accessories Sectorial Chamber for the Plastic Industry from ABIMAQ SINDIMAQ Brazil. In this interview, Jason asked him about ABIMAQ's services and business scope, his views on the economic situation in Latin America in recent years, and his expectations for this exhibition in China. Mr. Marcelo Zimmaro stated that their mission at the exhibition is to assist the Brazilian machinery industry in import and export activities, and they hope to find more allies and friends at this exhibition. For more detailed interview content, please stay tuned for the upcoming PRM reports. PRM is committed to collaborating with global media to bring more information about the world's plastics and rubber industry to everyone.

Plastic Bags on Roll Making Machine Series | CHAO WEI

Introducing a full range of Plastic Bags On Roll Making Machine Series from CHAO WEI, which is a pioneer plastic bag making machine manufacturer in Taiwan with more than 35 years of experience in this field. 【SPECIALTIES OF CHAO WEI】 Bag on Roll Machines T-Shirt Bag Making Machine Side Sealing Machines Bottom Sealing Machines Whole Plant Equipment 【ABOUT CHAO WEI】 CHAO WEI Plastic Machinery Co., Ltd. is an advanced manufacturer of plastic bag making machines with more than 35 years of experience with ISO 9001 & CE certificate in Taiwan. CHAO WEI’s main goal is to enhance the value of machines and to create new performance capabilities that will meet the customers’ production efficiency and profitability.

PRM-TAIWAN @ CHINAPLAS 2021 | Exhibition Opening

PRM Media Channel is happily reporting from CHINAPLAS 2021! In recent years many exhibitions have been canceled or postponed. Despite the COVID-19 pandemic, by implementing strict safety regulations, CHINAPLAS opens its door today once again to assist many exhibitors and the visitor to cultivate plastics and rubber industry. There will be many on-site and online activities expected to take place concurrently. Stay tuned to PRM Media Channel and PRM-TAIWAN B2B platform to gather more insight into CHINAPLAS 2021 activities. We will be posting more content and news about the event.

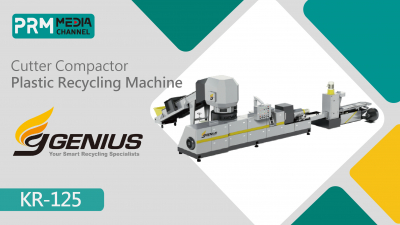

Cutter Compactor Plastic Recycling Machine - KRIEGER Series | GENIUS

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine [VIDEO HIGHLIGHTS] 0:00 Plastic Recycling Machine - KR-125 0:28 Belt Conveyor 0:41 Cutter Compactor 1:00 Main Extruder 1:11 User-Friendly Control Panel 1:26 Dual-Piston Filter 1:36 Die-Face Cutting Pelletizing [KEY FEATURES ] Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc. Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials. High torque precision gearbox. Low noise and steady operation. Die-face pelletizing is expected to reduce manpower costs. The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation. SAVE cost, energy, and time. The single extruder is suitable for clean materials such as injection leftovers and production waste. [COST SAVING] Saves energy cost up to 20% Reduces labor cost as only 1~2 operators are needed to operate the whole plant. [SUPERIOR FEATURES] /Compacting & feeding/ The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity. /Multiple Cooling/ Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. /Flexible Customization/ GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

2024 TaipeiPlas International Plastics & Rubber Industry Show| CHUAN LIH FA

At the TaipeiPlas, PRM-Taiwan interviews CHUAN LIH FA MACHINERY WORKS CO., LTD. In this exclusive feature, CHUAN LIH FA demonstrates their latest custom-designed injection molding machines, highlighting innovations that push the boundaries of technology in the plastic injection molding industry. In this video, you'll learn how their new machines offer significant space-saving designs, as well as the ability to handle multi-color production, making them a versatile solution for manufacturers. Discover how CHUAN LIH FA is not only advancing technology but also fostering talent and driving progress in this dynamic industry.

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

3 Layer Air Bubble Film Extrusion Line | CHI CHANG-

MACHINERY IN THE VIDEO: 3 Layer Air Bubble Film Extrusion Line from CHI CHANG MACHINERY APPLICATIONS: The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope.

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Food Processing Machine Solutions | HUNDRED MACHINERY

Since 1996, Hundred Machinery Co., Ltd. has been the professional automatic encrusting machine manufacturer in Taiwan. PRM Media Channel had an interview at the recent TAIPEI PACK and had a chance to introduces the companies automatic food processing machinery lines. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for similar videos!~ MAIN PRODUCTS/SERVICES OF HUNDRED MACHINERY:

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8 Nowadays, everything has been advanced to automation and connection to the Internet. Even in the Plastic and Rubber Industry, which we might consider as the traditional industry, it has been upgraded gradually through the industry 4.0 revolution. Let’s take a quick look to understand what are Industry 4.0 and IoT, and how does the Plastic and Rubber Industry apply it. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.

2024 CHINAPLAS Interview | HCI

We are here with Terence from HCI Converting Equipment at the CHINAPLAS. HCI is a specialist in the Converting Equipment and Slitter Rewinder machinery, able to provide from a single machine to whole plant equipment. We heard very valuable information from Terence, thank you so much!

High Speed Slitting Machine - S2A Series | YICHEEN

YICHEEN is a professional equipment supplier that specializes in soft-material cutting technology, including die cutting, sheet cutting, slitting and laminating. Since 1979 we have been supplying soft material cutting machinery. This has now transformed into state of the art high-precision customized cutting equipment, which meets worldwide standards and guidelines.

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.

Plastic Blow Molding Process Explained | PRM What to Say EP 13

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding. In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method. For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often. The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

Two Platen Injection Molding Machine 600TPIIR | CLF

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance. 【HIGHLIGHTS OF THE MACHINE】 Clamping Force 1800~4000 TONS Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature. Clamping force, mold opening stroke, and distance between tie bars are easy to customize. Quick and accurate mold adjustment makes the machine suitable for small lot flexible production. Uniform force distribution on mold ensures the high accuracy of the product. Uniform tension force on tie bars for the dramatic increase of service life. Simplified construction with no wearing problem on toggle clamp. Rigid machine structure, minimum deformation, and consistent product accuracy.