2024 NPE Orlando Interview | PARKER

We had the pleasure of meeting the passionate Mr. CT Teoh at the NPE show. Mr. Teoh gave us an insightful overview of the innovative PET blow molding machine he brought to the event. This cutting-edge machine features single material concept. Join us as we dive into the details and discover the big news Mr. Teoh has to share!

GMA 30th Anniversary - Extrusion Dies Empowered by Innovation | GMA

GMA Machinery Enterprise Co., Ltd. has manufactured extrusion-die and has focused on the technology of extrusion & coating dies for many years. In 2019, GMA welcomed its 30th year anniversary with abundant experience in this industry. GMA supports your business & creates wonderful life by the following values: - Excellent Product Performance - Quality Policy - Highly Precision Quality & Products 【Features】 - Complete Production Management - Precision Machine - In-house Chrome-plating Facility 【Industry Involved】 - Industrial Construction Material - Photoelectric Energy Saving - Aviation & Automotive - 3C Digital - Medicine Hygiene - Food Table Wares

2024 NPE Orlando Interview | GENOX USA

In this interview with Genox USA, we talk to Mr. O' Donnell about how Genox provides valuable machines and solutions for the plastic and metal recycling markets in America. He shares insights into the company's offerings and outlines their future plans for expansion in North America and Latin America.

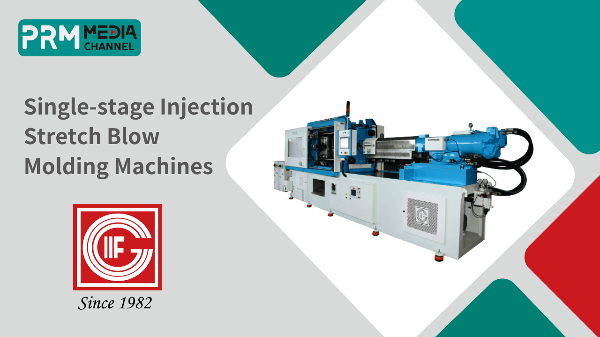

Single-stage Injection Stretch Blow Molding Machine | GOLFANG-

Golfang treasures what have been entrusted... customizing special machine with molds for each customer. Golfang specializes in the development and manufacture of " single-stage injection stretch blow molding machine". Provide customers with a whole set of production equipment which includes customized machine and mold. Strictly control the quality and reliability of all assembly parts. Do the test runs repeatedly including mold testing and material testing before delivery. Obtain the most stable molding parameters based on the molding characteristics of the plastic specified by the customer and the adjustment during the bottle production. Meet the customer’s quality and production capacity requirements. Finally, after the machine acceptance, transfer the molding technique to the equipment user and do the personnel training. The equipment ca be run in full-time production with durability, high-efficiency, and high-stability, which creates the best return on investment for the customer. It is also the first choice for producing high-end plastic packaging containers when small quantities, varieties, and high quality are required at an early development stage. The Golfang team has accumulated many years of experience in the field of plastic product: PPSU baby bottles, PC/PMMA lampshades (LED light bulbs), HIPS yogurt bottles, PP/PE/PET medicine bottles, TRITAN water bottles, PET/PETG cosmetic bottles, household product bottles, etc... exquisite packaging containers. Also cooperated with the customers in developing products for well-known brands, include Pigeon, AVENT, Nuby, Yakult, Unilever, LOREAL, AVON, SHISEIDO, Pfizer, etc. Mold development is nothing more than a solution to product market demand. In the field of injection blow molding, Golfang insists on research, design, and manufacture of exclusive molds, and never relies on others, because we know that molds are designed and developed in response to the equipment. When customers evaluate and launch new product according to the market trend, what they need is stable quality and the chance to get ahead of the game. Therefore, with Golfang’s established and mature molding technique, whether it is the mold’s durability (2 million cycles guaranteed) or the delivery time, Golfang is always the most reliable choice for the customer. The common design of mold bases and mold parts is able to save mold costs and improve competitiveness for the customers. It provides them with the most economical solution. Golfang would communicate on product sizes beforehand and suggest for minor alteration. In such a way, Golfang gains good recognition from the customers.

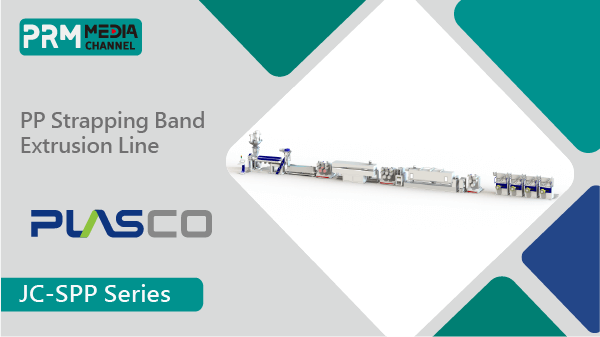

PP Strapping Band Extrusion Line (JC-SPP) | PLASCO

PLASCO's JC-SPP Series of extrusion lines are designed to produce PP strapping bands, which are commonly used for light- and medium-duty applications, such as for securing newspapers and magazines, carton boxes, and pallet freight shipments. 【Machine Spec】 Applicable Material: PP Screw Diameter (mm): 90 / 100 / 120 Strap Width (mm): 5-19 / 12-19 Extrusion Capacity (kg/hr): 180 / 250 / 380 Straps Produced: 4-2 / 8-4 / 8-6 【Application】 Newspaper strap Carton box strap 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Plastic Welding Machine at K 2022 | TAI YEN

By interviewing Mr. Tony, from Tai-Yen Industrial Co., at K 2022, we have a quick understanding or their solution and product series, such as High Frequency Plastic Welding Machine and Ultrasonic Plastic Welding Machine.

Product Enhancement Through In-mold labels & Heat Transfer Films | XIANG IN

Have you ever wondered that your products do not look good and attractive? There is a simple way to enhance your product outlook and increase the quality and profitability. Throughout the interview with Ms. Penny, General Manager from XIANG IN ENTERPRISE, we have discussed advantages by using in-mold labels and heat transfer films to level up your products. Moreover, both of these two techniques not only be used in plastic, but also apply on wood, glass, metal and some particular materials. XIANG IN has been dedicated to developing its technique and improving their inspection. Therefore, the competitiveness of their products could not be replaced due to their strength of expiration and accurate quality inspection.

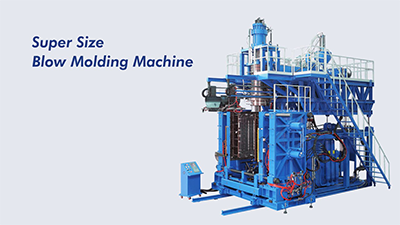

Blow Molding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. [Products List] + Small Blow Molding Machine + Medium Blow Molding Machine + Medium Co-extrusion Blow Molding Machine + Large Blow Molding Machine + Supersize Blow Molding Machine + Double L-Ring Drum Blow Molding Machine + Semi-auto Stretching Blow Molding Machine

Extrusion die and peripherals manufacturer | GMA

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the one of the best manufacturer in the world. Based on comprehensive processing equipment, GMA is able to exercise strict quality control throughout the whole in-house process from product design, manufacturing, assembling and inspection which, in turn, has earned customers’ continuous recognition and praise.

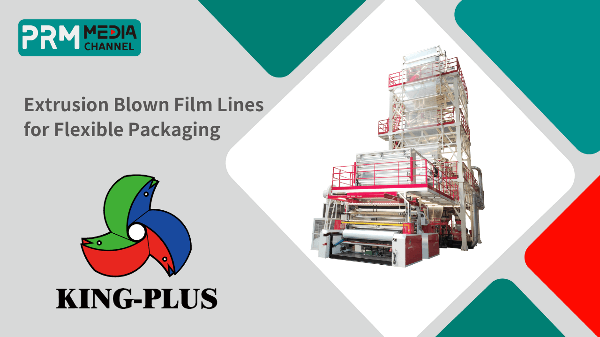

Extrusion Blown Film Lines for Flexible Packaging | KING PLUS

Three-layer blown film machine for lamination film Including: Auto air ring Gravimetric dosing system Internal bubble cooling system (IBC) In-line thickneess gauge Oscillating haul-off Back to back double winders Customized blown film machine to meet your need! Welcome to contact us!

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

PK-90CSV MHB Single Head Single Station View Stripe Blow Molding Machines | PARKER

Fully electric model machines are available.

PA/PET Monofilament Extrusion Line (JC-MNN) | PLASCO

PLASCO's JC-MNN series of extrusion lines utilize a dual-stage drawing/single-stage heating process to produce high quality PA6, PA66, PET or PP monofilament extrusion line. 【Product Spec】 Applicable Materials: PA/PET Screw Diameter (mm): 50 / 55 / 65 / 80 Filament Diameter (mm): 0.12-1.00 / 0.12-3.50 / 0.50-3.50 Extrusion Capacity (kg/hr): 35 / 50 / 75 / 120 【Application】 Rope Toothbrush Longline monofilament Fishing line Tennis strings Fishing net 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Campaign Video|EG-8002 Duplex Center Winding Slitter Rewinder|Nicely

Nicely is preparing to showcase our expertise globally. Our standout model is the EG-8002 Duplex Center Winding #slitterrewinder for #label #paper #processing. With advanced technology, superior tension control, and versatile #automation, it handles diverse #materials seamlessly. Nicely focuses on delivering tailored solutions, offering customized slitter rewinders, automation upgrades, and control system modernization. Each step of our process is carefully designed to address specific customer needs while aligning with the latest industry trends.

Plastic Injection Molding Innovations and Green Solutions | KING'S SOLUTION

Livestream time: November 20th at 19: 00 (GMT +8, Taipei) The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions. What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei) 【VIDEO OUTLINE】 00:00 Opening 00:59 KING'S SOLUTION CORPORATION 02:00 "Green Solution, Machine Soulmate" Slogan 03:04 Why to customize the machines? 05:00 Customized Machine Series 06:00 Market Challenges and Successful Cases 10:38 5 Gallon PET Preform Injection Molding Solutions 12:35 Advantages of KING’S in 5 Gallon PET Preforms 16:16 Trends in Injection Molding Market 18:40 LPM Application Examples 23:00 LPM Method vs Epoxy Method 26:00 After Sales Services and Customer Relations 28:55 Message to Current and Potential Customers Know PRM Media Channel more on: PRM Media Channel Website: https://bit.ly/3uqdubs PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Online Forum 《Packaging Trends and Future》| 2022 TAIPEI PACK

Event date: June 23rd, 2022 10:00-12:00

Gravimetric Technology at K 2022 | MAGUIRE

Founded in 1977, Maguire Products manufactures gravimetric blenders and feeders, volumetric feeders, ULTRA low energy dryers, conveying systems, extrusion control systems, loss in weight extrusion control, and related auxiliaries for Plastic & Rubber industry. It was a great honor for PRM-TAIWAN to invite Frank Kavanagh — Vice President Global Sales and Tony Tsai — Sales Manager (Taiwan) from Maguire. The conversation was mainly about the biggest challenge during the pandemic and how to integrate product innovation into application of Circular Economy, Digitalization, Climate Protection, which was the 3 main topics of K 2022. In the end, Mr. Kavanagh also talked about their main goal of the attendance. For more information, check the video!

Plastic Bag Making Machine | WorldSteel

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device. Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible. Suitable for already perforated and/or folded films. 【Company Introduction】 World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.

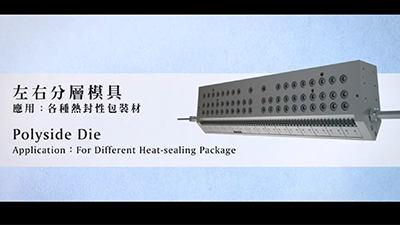

Feedblock | GMA

Feedblock - Polyside Die-GMA Two or triple manifold inlet design, plus feed block for multi structures, the width of stripe is adjustable, the adjusting range can be customized, flow adjusting design and adjustable lip can be applied on different thickness product. Application: 1. Heat-sealing food package box 2. Medicine package 3. Recycle material can be used on side to avoid waste Feature: 1. The stripe width is adjustable 2. Plus feed block, for more and different multi structures

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Digital Transformation for Packaging Industry | Taiwan Packaging Association

In this video, we interview the new Chairman of Taiwan Packaging Association, Mr. Benker Liao. Throughout this video Mr. Liao introduces the importance of participation in the international exhibitions for the Packaging Industry and how it was affected during the pandemic. The new Chairman has encouraged the players of Taiwan Packaging Industry to make a change in mindset, organizational and business transformation for Online Marketing.

Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Industry Insight: Blow Molding Machine and Printing Machine Market India

KYMC on PRM-TAIWAN B2B Platform: https://bit.ly/3l2uZdT CHEN WAY on PRM-TAIWAN B2B Platform: https://bit.ly/3l3cqGz It was a nice interview with Mr. Kunal Mehta, who is from KYMC India and also the agent of CHEN WAY in India. At this interview, Mr. Kunal willingly shared the advantages of having a local partner in India, suggestions to foreign manufacturers/companies who plan to enter the Indian market, and how manufacturers provide support to local dealers under pandemic circumstances. Moreover, we also discussed the pros and cons of physical and online exhibitions. Let's watch the interview video together and leave your comment in the comment section!