Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

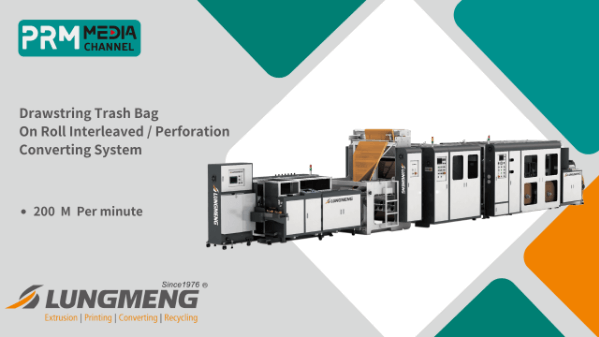

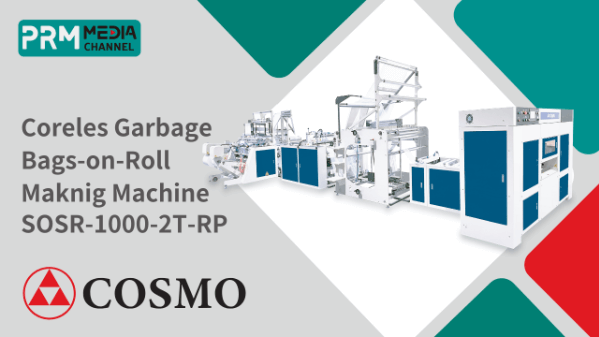

Coreles Garbage Bags-on-Roll Maknig Machine SOSR-1000-2T-RP | COSMO

Flexible production with star sealing and bottom sealing. Shuttle system & 4 shafts re-wind system for stability and high out put. Servo driven system for high production capacity. From film roll to finished bag roll, computer control over the entire process. It's easy to adjust the bag length, film tension, and production speed on touch screen. Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed. Auto reel changing device and bag pull off device on re-winder. Automatically stop on miss-color scanning / film breaking / running out of film. MODEL SR(2)MR(1)-1000-OS-2T-R4S Bag Length 350 - 1500 mm Finished Product Ø150 x 600 mm (single line) Ø150 x 250 mm (2 lines) Film Thickness 0.008 - 0.060 mm / layer (bottom seal) 0.008 - 0.035 mm / layer (star seal) Film Roll Size Ø1000 x 900 mm (single roll for bottom sealing) Ø1000 x 500 mm (2 rolls for star sealing) Production Speed 150 meter / min / line (max) Power 220V, 3Phases, 50/60HZ, 30KVA Heater 6.2 KW Required Air Compressor 6HP (not included) Dimension L10000 x W2600 x H2500 mm * 規格如有變更改進,恕不另行通知。

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6 Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event PRM Theme Pavilion, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry. Let's take a look at the PRM What to Say episode 6, where we are evaluating and introducing the next PRM Theme Pavilion which focuses on the Packaging industry. In the video, you will learn more about not only what this event is about, but also the benefit of the event for global visitors, how the event is planned and concentrated on a specific focus with the selected machine manufacturers and machinery lines that a packaging business all need.

Quick Mold Change - Clamping System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Seaming Machine | WEBCONTROL

Seaming Machine - Webcontrol Purpose of Machine : For Shrink sleeve. Features -Stable and heavy-duty frame for high speed operation of 300 m/min. -Adjustable forming plate creates efficient operation. -Auto solvent feeding control. -Auto tension control for unwind/rewind unit to maintain the optimun tension. -Accurate product width. -Cantilevered rewind/unwind shaft for fast roll changeover. -PLC with color touch screen control system. -Rewind oscillation control to produce high quality rolls.

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.

Packaging Industry Trends and Obstacles | PRM What to Say EP5

In the fifth episode of the PRM What to Say program we interview Ms. Wang, the Chairperson of Taiwan Packaging Association. Through the interview that our team member Sunny held, we touched several current topics related to the packaging industry, online and physical trade shows, food food safety, shelf life and modern packaging designs, the association’s support for the members and so on. Since the beginning of the outbreak many machinery industries are facing several common obstacles such as logistics, machinery installation and maintenance. For the many machinery categories, the demands are suspended. However, for the packaging industry, the situation is more specific. Due to the global lock downs, the housing economy has been revived and the needs for food packaging and cargo packaging boomed. On the other hand, the machine manufacturers are still facing the common obstacles of the pandemic to reach out to their customers.

High Speed Zipper Strip Hot Lamination Side Sealing Machine | MING JILEE

【Machine Features】 Taiwan-made and stable PLC controller The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan. Zipper Bag Side Sealing Machine is equipped mark sensor for printed material. For getting the best quality of zipper bag product, unwinding station is mount the auto tension control. The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. Ultrasonic welding is design by motor driven for highest speed production. The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. 【Company Intro】 Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

TAIPEIPACK 2023 On-site Tour| PRM-TAIWAN

TAIPEIPACK 2023 exhibition tour is coming! Follow Daniel to learn about Taiwanese packaging manufacturers And the first-hand industry information!

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry As PRM Media Channel, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! The Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the company’s profile and the current situation of COVID-19 in Mexico, the challenges they are having due to the pandemic, and their solutions to overcome those challenges.

5 Benefits of Flexo Printing Machines | PRM What to Say EP11

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable. Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface. So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

K 2022 ON-SITE TOUR | PRM

Can't attend K 2022 in person? PRM will show you the most interesting exhibition highlights on【K SHOW 2022 ON-SITE TOUR】 Taiwanese manufacturers are gathering at K 2022 and showcasing their new technique of plastic & rubber machinery. You can also feel the good vibe from the show. 【Video Outline】 0:00 Introduction 0:16 CHAO WEI PLASTIC MACHINERY | Plastic Converting Machines 0:37 YE I MACHINERY | Plastic Recycling & Material Processing Machinery 1:36 HO HSING PRECISION INDUSTRY | Parts and Components 2:06 HUARONG GROUP | Injection Molding Machines 2:50 SUNKIST CHEMICAL MACHINERY | Thermoforming Machines 3:17 MING JILEE ENTERPRISE| Extruders & Extrusion Lines 3:41 QUEEN’S MACHINERY | Extruders & Extrusion Lines 3:52 CHI CHANG MACHINERY | Extruders & Extrusion Lines 4:17 HSIN LONG | Molds & Dies 4:38 FORMAX | Auxiliary Equipment and Integrated Automation 4:46 YEN SHENG MACHINERY | Extruders & Extrusion Lines 5:01 BOTHEVEN MACHINERY | Auxiliary Equipment and Integrated Automation 5:20 GENIUS | Plastic Recycling & Material Processing Machinery 5:40 JUMBO STEEL | Extruders & Extrusion Lines 6:10 WORLDLY INDUSTRIAL | Printing Machinery 7:00 PRM TAIWAN

Plastic Recycling in Japanese Market at K 2022 | POLYSTAR

We were glad to have an interview with Mr. Kenji Murai, agent of POLSTAR in Japan, who shared his observation of plastic recycling in the Japanese market and his experience doing machinery business.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Blow Moulding Machine |FONG KEE

Blow Moulding Machine - High Speed Blow Moulding Machine-hba-ddgv-Fong Kee Specializes in Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Ultrasonic Metal Welding Machine-ULTRA6200-M-WT | MING JILEE

ULTRA6200-M-WT Ultrasonic Metal Welding Machine

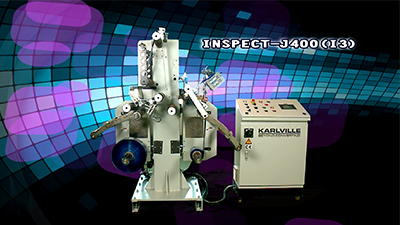

Inspection Machine | WEBCONTROL

Webcontrol Machinery Corp.- Manufacturer of inspection machine and more. More information about inspection machine: 1.Inspection Rewinding Machine- INSPECT-J300 2.Doctoring Rewinder Machine- INSPECT-H300/H400/H500 Webcontrol Machinery Corp has been specializing in manufacture of inspection machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our inspection machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast inspection machine service ensure our worldwide customers must be satisfied.

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

All-Servo Drive T Shirt Bag On Roll Bag Making Machine ft. Swing Type Feeding System | PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

3000 Ton Plastic Injection Moulding Machine | CLF

3000 Ton Plastic Injection Moulding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.