Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

New Brand Release | PRM-TAIWAN

Throwback to PRM-TAIWAN's New Year Resolution of 2019, the new brand image! PRM-TAIWAN(Plastic and Rubber Media Taiwan) is here to start 2019 with a BAM! Standing firmly as the number 1 platform for Taiwanese plastics and rubber manufacturers, our dreams does not stop here. Although already influential, our goal is to further penetrate global markets including but not limited to the Spanish, European, African and Russian markets. To show our resolve, PRM-TAIWANwill like to present to you our brand new look! The logo is a manifestation of PRM-TAIWAN. With the color representing our mindset, shape representing our physicality and missing pieces as our motivation. Now let us embrace 2019 and shine to the world! Read more: https://www.prm-taiwan.com/industry_i_2019011800001.html

PRM-TAIWAN @ CHINAPLAS 2021 | Exhibition Opening

PRM Media Channel is happily reporting from CHINAPLAS 2021! In recent years many exhibitions have been canceled or postponed. Despite the COVID-19 pandemic, by implementing strict safety regulations, CHINAPLAS opens its door today once again to assist many exhibitors and the visitor to cultivate plastics and rubber industry. There will be many on-site and online activities expected to take place concurrently. Stay tuned to PRM Media Channel and PRM-TAIWAN B2B platform to gather more insight into CHINAPLAS 2021 activities. We will be posting more content and news about the event.

Sheet Cutting Machine | YICHEEN

Description: Friendly interface, PLC computer touch-panel screen control system. Non-hydraulic design, no pollution, low noise, best for using in dustless room. Servo motor control feeding (for EVA sheet cutting tolerance +/-1mm). Modulating control for tension control, it keeps cutting stable. Anti-static PU roller drive for reducing scrape happened. Optional devices: Shaftless unwind stand (electrical left/right moving), EPC (Edge Position Controller), Slitter, Punching device (electrical left/right moving), Automatic stacker, Static eliminating device,

Proportional Pressure Regulator Valve | QKL-B2T+External Pressure Sensor | KAOLU

00:00 QKL-B2T Proportional Pressure Regulator Valve + External Feedback Pressure Sensor Product Introduction 00:21 QKL-B2T+External Feedback Pressure Sensor Description 00:29 Product Function: Boost Flow 00:40 Product Feature: Remotely controls cylinder pressure What is a Proportional Pressure Regulator Valve? In pneumatic world, a proportional pressure control valve is used to control downstream air pressure with an electronic signal. The input electronic signal is proportional to the span of the output pressure. For example, 0-10VDc of command signal corresponds to the output pressure span of 0 - 10 bar, with linear proportion relationship. Type of Proportional Pressure Regulator Valve? Kao Lu offers three types of electronic proportional pressure regulator: pressure ranges from vacuum -1~0bar, low pressure 0~2bar, 0~4bar, 0~8bar, medium pressure 0~16bar, 0~30bar, up to high pressure 0~70bar. In the high pressure control, the resolution can reach 0.5~0.6 bar. Proportional Pressure Regulator Valve Working Principle? Proportional Pressure Control Valve adopts a closed loop design and consists of two solenoid valves, an internal pressure sensor and an electronic control; according to an analog signal input, one solenoid valve is used to control the air intake and the other is used to control the pressure. Both valves work together to achieve a precise proportional pressure control. The proportional pressure regulator adopts two types of input signals: 0-10VDC or 4-20mA, and three types of monitor output signals: 1-5V, 0-10V or 4-20mA.

Innovative Technology in Plastic Recycling | BoReTech-

BoReTech is a leading company in the plastic recycling industry. With more than 30 years experience in the industry, BoRetech is introducing its brand new designed ES process.

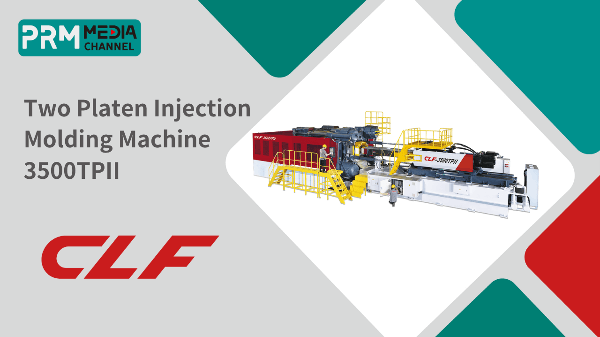

Two Platen Injection Molding Machine - 3500TPII | CLF-

➡️ Maximum injection weight 34 KG. ➡️ High stability, High efficiency, High energy saving.. ➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy. ➡️ Direct pressure clamping to make the mold evenly stressed. ➡️ Smooth, stable and powerful. ➡️ Uniform tension force on tie bars for dramatic increase of service life. ➡️ Simplified construction with no wearing problem on toggle clamp. Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor *Gripper bag transfer system, most advanced design *Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap *Union Special Sewing machine customized model available For more information, visit http://www.botheven.com.tw

2024 CHINAPLAS Interview | BoReTech

We are here with Mr.Alan Ou from ZHEJIANG BORETECH ENVIRONMENTAL ENGINEERING CO., LTD. at the CHINAPLAS. BoReTech is a leading company in the plastic recycling industry, that strives to solve plastic waste and give it a second life. With more than 30 years of experience in the industry, BoReTech can process different materials from different countries and gain know-how experience.

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

PRM 2021 Market Report through Data Analysis | PRM What to Say EP4

We already left the first half of 2021 behind, it still has been a tough period for many industries including plastics and rubber industry as well. Here, we bring a comprehensive market report through analyzing the data from PRM-TAIWAN B2B platform including global buyer inquiry data by categories. In the fourth episode of the PRM What to Say program Resul, the reporter of PRM Media Channel, invited two of our colleagues from PRM to share their observations of the global market. Daniel is responsible for PRM-TAIWAN B2B Platform which is a marketplace for plastics and rubber machinery, auxiliary and materials. Regarding the platform, Billy is responsible for matchmaking global buyers and Taiwanese suppliers. Through the data we have gathered from PRM-TAIWAN B2B Platform, Daniel and Billy are replying to many different questions that any player of the industry are asking currently. Such as how the situation of the market is, what sub industries are affected negatively and/or positively during the pandemic, what category of the machineries are demanding most for the purpose of what type of applications, and so on. VIDEO OUTLINE 0:00 Highlights in Episode 4 & Video Intro 0:23 Duty of PRM in Plastics and Rubber Industry 1:30 How PRM Market Data is reliable? 2:53 Buyer behavior on PRM-TAIWAN B2B Platform 4:18 Market Insight through PRM Inquiry Data 6:03 Market Demands in the First Half of 2021 7:54 Market Reflection on PRM During the Outbreak 9:50 Video closing Know us more on PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #PRMMediaChannel #PRMWhatToSay #Inquiry #Data #MarketReport #PRMTAIWAN #Plastics #Rubber #Industry #GlobalMarket #Machinery #B2Bplatform

Practical Solutions & Plastic Converting Equipment | HCI

【SPECIALTIES OF HCI】 Slitting Machines Rewinding / Inspection Machines Pouch Making Machines Medical Sterilization Pouch / Reel Making Machines Shrink Sleeve Seaming / Cutting / Doctoring Machines Embossing Machines 【ABOUT HCI】 Established in 1982, HCI Converting Equipment Co., Ltd. is a specialist in the design and manufacture of a full range of Roll-to-Roll and Roll-to-Sheet Converting Equipment and machinery for Flexible Packaging and Semi-Conductor, TFT-LCD, optoelectronics, Medical Industry (Sterilization Pouch/Reel Making Machine、Meltblown Fabric) and relative industries.

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com [email protected]

Solventless Lamination - Webcontrol

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.

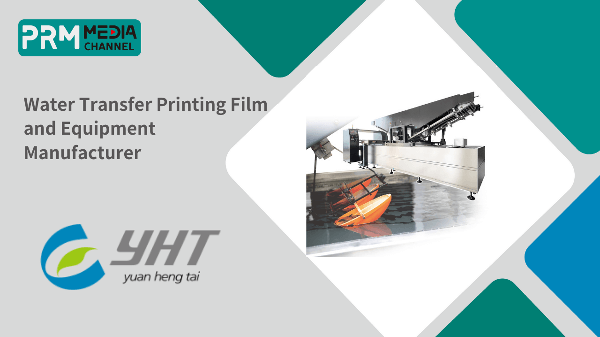

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw / Automatic Log Roll Cutting Machine Features / Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down. PLC control system Auto change cut size setting in the same shaft. Precise and smooth positioning. Multi-speed cutting rolls to improve operating efficiency and maintain high quality. The blade has different angle changes according to different materials, reducing the number of tool changes. / Advantages of Yicheen / Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions. / links of Yicheen / Contact us: https://bit.ly/3q8KLaK Subscribe us: https://bit.ly/3wGjjU3 Product Info: https://bit.ly/3tU2QdK

Double Lines T-Shirt Bags Making Machine:ST-88-G2 | COSMO

Fully Automatic High Speed Double Lines T-Shirt Bags Making Machine with Hot Slitting & Side Gusseting Device. Model : ST-88-G2 Machine Features: https://www.cosmo886.com.tw/en/products_i_High_Speed_T-Shirt_Bag_Making_Machine_with_hot_Slitting_and_Side_Gusseting_Unit_ST-88-G2.html ➤Contact Us COSMO MACHINERY CO., LTD. Web: https://www.cosmo886.com.tw

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

Crystallized Hopper Dryer(PET Crystallizer) - Engliish Subtitle | Yann Bang

The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time.

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

Crystallized Hopper Dryer(CHD) | YANN BANG

Our PET / PLA Crystallizer is a closed-loop heating system continuously to re-crystallize PET amorphous resin and covert it into crystalline state. FEATURES The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time. YANN BANG Crystallized Hopper Dryer is the best choice for PET users. 1. SAVE COST. With YANN BANG's patented drying technology,the crystallized hopper dryer mixes the resin evenly while drying and shortens the drying time. 2. PREVENT BRIDGE MAKING. When drying oily,sticky,abnormal shaped resin,it is easy to have the bridge making.To use the crystallized hopper dryer can prevent the bridge making effectively. 3. NUMEROUS MIXERS AVAILABLE. Different kinds of unique mixers to suit for your special needs.

High Speed PP/HDPE Raffia Tape Extrusion Plant | Raffia Tape Extrusion Line | HAO YU

【New generation high speed PP/HDPE raffia tape extrusion plant - GV series (Green Veloz)】 / Raffia Tape Extrusion Line/Plant Features - (HY7/SP-80GV) / ⚡️Suitable for making 100% recycle PP/HDPE materials ⚡️Finish products complies with the requirement of GRS(Global Recycled Standard). ⚡️Meet the requirements of companies interested in selling their products to ESG approved companies. ⚡️Rapid color changing.

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

Full Electric Co-EBM with visi strip (4 head double station) | CM-90.55FVH2D | Chia Ming

CM-FE90.55FVH2D Full Electric Co-Extrusion Blow Molding Machine - Continue extrusion with horizontal movement and toggle clamping. Fully automatic and highly efficient production. -------------------------------------------------- Why Go Full-Electric? ► Energy savings 20%~70% ► Precise and more efficiency ► No hydraulic, less noise, no oil leakage ► Easy maintenance -------------------------------------------------- / Key Features / ★ All-electrics (Fully servo motor driven) ★ Servo Drive Die Head Nodding System ★ Full Electric Parison Control System ★ Crank Type Servo Drive Carriage Movement ★ Visi Strip function ★ Auto deflashing device ★ Backhoff, Germany and Keyence, Japan control system -------------------------------------------------- / Other Features / ★ Equipped with robot arm (2D Gripper) ★ Post cooling ★ Auto loading system ★ Residue conveyor to crusher ★ Built by standard components, i.e. Beckhoff, Festo, SMC, Toshiba, Tokimec, Schneider, ABB, Omron, ensuring straightforward maintenance at lower cost and global spare parts availability -------------------------------------------------- / Optional equipment or function/ ????Support the “Industrial” internet of things. (More info, please contact.) -------------------------------------------------- / Application/ Jerrycan/ Food packaging/ drinks/ detergents/ reagents/ cosmetics/ medicines/ engine oil bottles/ lubricants/ jars/ home products/ car parts/ decoration parts...

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Plastic Wood Composite Profile Extruding Machine | CHEN YU

Plastic Wood Composite Profile Extruding Machine | CHEN YU CHEN YU PLASTIC MACHINE CO., LTD is a professional designer and manufacturer in Plastic Wood Composite Profile Extruding Machine.

Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!