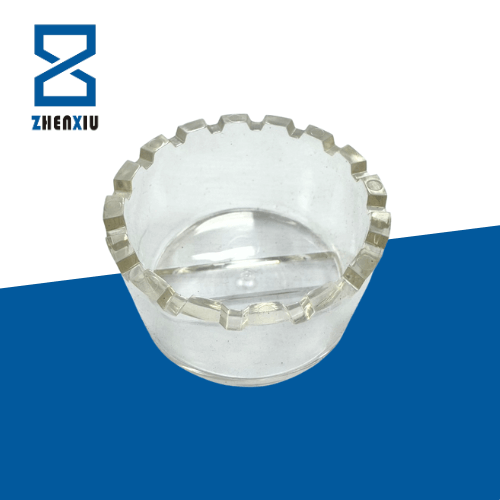

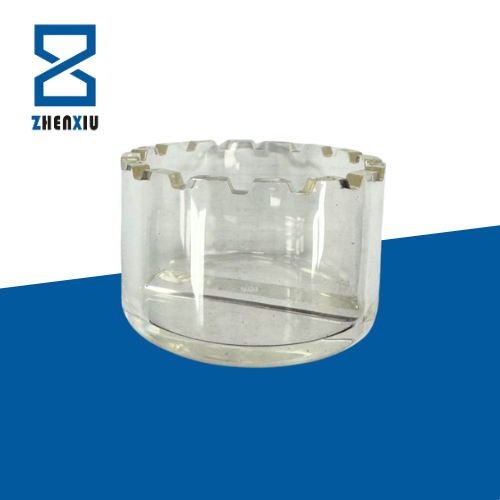

Optical Injection Molding Technology is a specialized process designed for high-precision and high-transparency plastic components, ensuring minimal internal stress, superior optical clarity, and defect-free production without bubbles, flow marks, or deformation. This technology is ideal for LED lenses, optical lenses, transparent instrument covers, medical device housings, and automotive light covers, where optical performance is critical.

This process commonly utilizes PMMA (Acrylic), PC (Polycarbonate), and COP (Cyclic Olefin Polymer), combined with high-precision polished molds and advanced injection parameter control to achieve superior optical performance and durability. Additionally, high mold temperature control technology is applied to eliminate internal stress and enhance product stability, ensuring optical-grade quality.

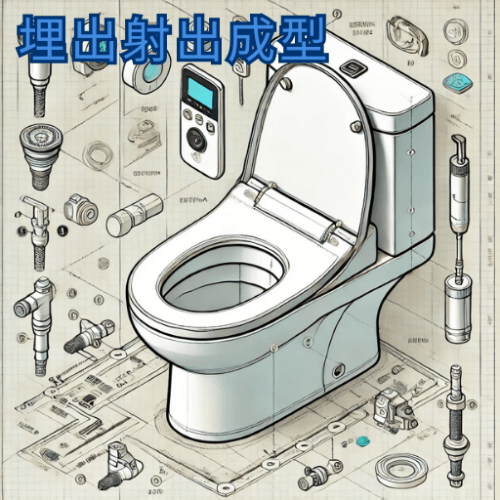

Industry Applications:

Optics & Lighting: LED lenses, diffusion sheets, light guide panels

Automotive & Electronics: Headlamp covers, display panels, transparent casings

Medical Devices: Optical-grade instrument covers, transparent medical components

Consumer Products: Transparent enclosures, precision optical parts

|

|