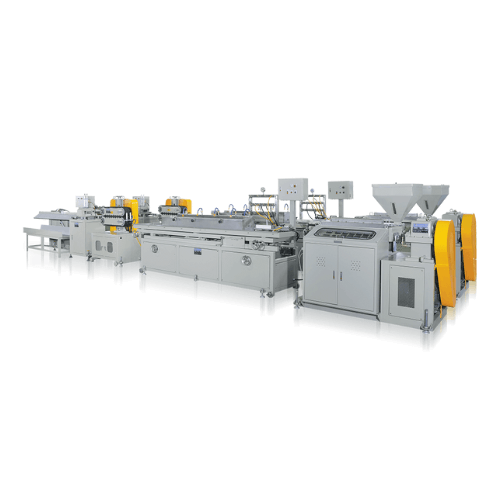

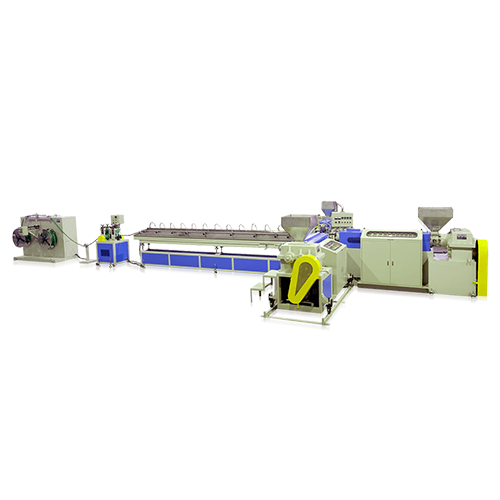

The WPC profile extrusion line is a set of machines used in the production of WPC boards.

Differences between WPC profile extrusion and general profile extrusion

WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products.

How does WPC profile extrusion line work?

The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it.

The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product.

Advantages of WPC profile extrusion line

- Efficient and consistent production of high-quality WPC profile products.

- The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties.

- Highly automated, reducing the risk of human error and increasing efficiency.

Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer

As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.

|

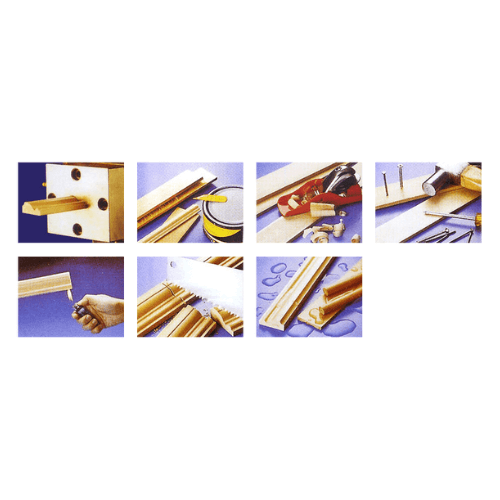

Wood-plastic Composite (WPC) Seat

Wood-plastic Composite (WPC) Floor

Wood-plastic Composite (WPC) Pillar

Wood-plastic Composite (WPC) Beam |

Wood-plastic Composite (WPC) Bookcase

Wood-plastic Composite (WPC) Room

Wood-plastic Composite (WPC) Ceiling

Wood-plastic Composite (WPC) Screen |

Wood-plastic Composite (WPC) Totem

Wood-plastic Composite (WPC) Table

Wood-plastic Composite (WPC) Window

Wood-plastic Composite (WPC) Door |

Wood-plastic Composite (WPC) Fence

Wood-plastic Composite (WPC) Wall

Wood-plastic Composite (WPC) Pavilion

Wood-plastic Composite (WPC) Decorate |

New Revolution Wood Plastic Composite Material

- The wood plastic composite process is a unique patented technology that can be injection and extrusion molded sandwich, finished products have a smooth surface and internal micro-bubbles nuclear characteristics can enhance product value-added.

- Product weight loss reached lightweight while reducing the cost of the raw materials used.

- Reduce the cooling time, and improve production efficiency.

- Reduce the product shrinkage and warpage problem.

- Do not use chemical blowing agents that will not produce the freon gas of the impact on the environment through the European Union in 2013 disabled 6 chemicals blowing agent restrictions.

- Can be used in the non-chemical blowing agents can be added to plastic materials.

- If didn't use physical foaming, the function of the general injection molding machine and extrusion line is the same original raw materials of chemical blowing agents, can continue using the machine.

- Lightweight the Product and Reduce the cost.

- Innovation and Huge Progress.

| Model | CY-50PW | CY-65PW | CY-70PW | CY-80PW | CY-100PW |

|---|---|---|---|---|---|

| EXTRUDING CAPACITY (KGS/HR) | 20 ~ 40 | 30 ~ 55 | 35 ~ 65 | 70 ~ 100 | 70 ~ 100 |

| SCREW DIAMETER (MM) | 50 m/m ø | 65 m/m ø | 70 m/m ø | 80 m/m ø | 100 m/m ø |

| PROPERTY | METHOD | TEST RESULT |

|---|---|---|

| SPECIFIC DENSITY | ASTM D648 | 700.00 kg/m³ |

| MOISTURE CONTENT | ASTM D648 | 1.70% |

| BENDING STRENGTH | ASTM D1037-93 | 27.74 N/mm² |

| COMPRESSION TEMPERTURE | ASTM D1037-93 | 11.6749 N/ mm² |

| SOFTENING TEMPERATURE | ASTM D648 | 83.0℃ |

| FIRE RETARDANT | UL 94 | V² |

| SCREW WITHDRAWAL | BS 6948:1989 | 91.85N |

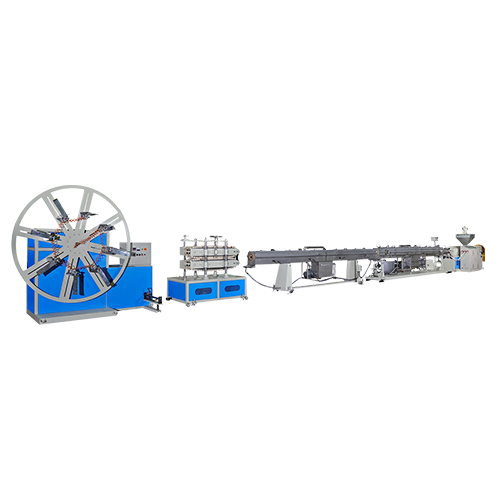

Video of Wood-plastic Composite (WPC) Profile Extrusion Line

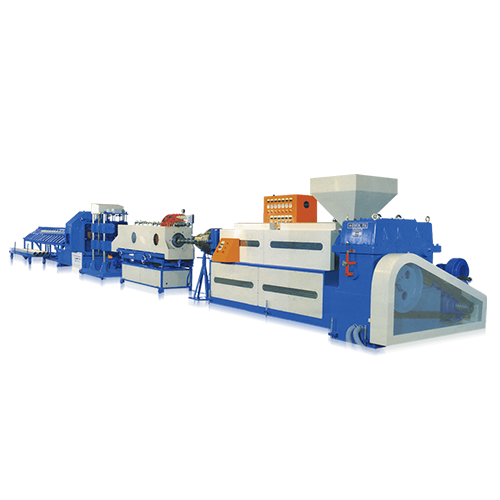

Video of PVC Profile Extrusion Line