OPP/BOPP Labeling Machine For Square & Round Bottle -Automatic High Speed

カテゴリー : ラベルプリンタ

1. Application for labeling round and square shape containers. 2. Fully automatic rotary operation for 330ml-4000ml bottles.(with certain change of parts). 3. Machine frame made of stainless steel 304. 4. PLC electronic control, touch screen monitor and electronic speed control(frequency inverter). 5. With a star-wheel carrying containers firmly while dispensing , provide stable dispensing performance under high-speed operation. 6. Use servo motor to synchronously tracks label supply, label cutting and use specially designed vacuum drum to ensure precise labeling. 7. Three-phase PLC and AC variable control with a synchronized tracking and control system to maintain label cutting accuracy in different running speed. 8. Centralized lubrication system for easy maintenance. 9. Detecting in feed situation with sensor, automatically adjust labeling speed according to feeding situation of production line, making production line coherent. 10. System safety device: when malfunctions such as irregular torques and abnormal feeding occur, machine will automatically stop for operation safety and machine durability. 11. Automatic label proofread system controller made in Germany. 12. Automatic speed self adjustment to contact other machine.

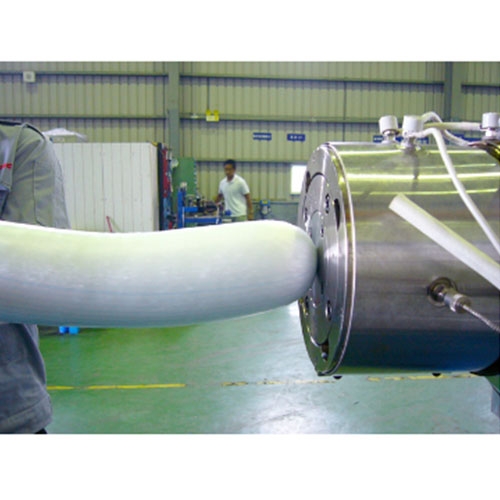

LDPE Foam Tube&Rod Extrusion line

カテゴリー : パイプおよびプロファイル用押出ライン

LDPE Foam Tube&Rod Extrusion line : With proper mixing of melted resin & blowing agent, provides most homogeneous mixing. Accurate blowing agent injecting quantity and temperature control to stabilize the foaming process. High level safety control, system will be shut down automatically when extruder motor failure or high pressure.

Inline Coating & Lamination Application-The coating & lamination with maximum efficiency

カテゴリー : 工業用ラミネート機械

Inline Coating & Lamination Application (The coating & lamination with maximum efficiency) The main concept of inline coating application is to simplify the complete production process by integrating the printing press with the coating and lamination application unit. The inline coating units can include Reverse Gravure or Direct Gravure / Flexo Coating or Semi-Flexo Coating / Waxer or Hotmelt (Coating/Lamination). It can save unnecessary wastage during the production and increase production efficiency. If you are looking for suitable inline coating or lamination integration, this is the unit for you to customize. KYMC

Euroflex-The Flagship Press

カテゴリー : プレスオフセット

The state of the art gearless flexo press and is one of the best valued gearless press on the market. As the flagship press is equipped with the highest automation, precision, stability, and cleaning technologies available. The press technologies along with its structural design allow for maximum press speed, working on the widest range of substrates. If you are looking for maximum efficiency and minimum human intervention, this is the press for you to customize. KYMC

ニードルパンチングセクション

カテゴリー : 油圧パンチングマシン

送りシステム、プレニードルパンチングマシン、フィニッシュニードルパンチングマシン、エッジカッターなどの周辺機器を含む完全なニードルパンチングセクション。テイラーは顧客のニーズに応じて完全なニードルパンチングラインを作り、生産の大きな柔軟性につながります。幅広い用途で、ジオテキスタイル、カーカーペット、ろ過、マットレスなどをカバーしています。