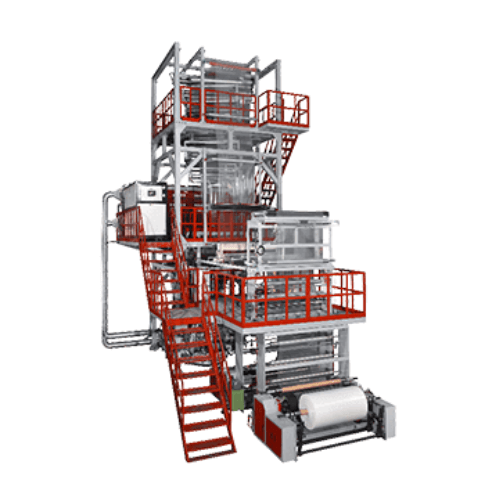

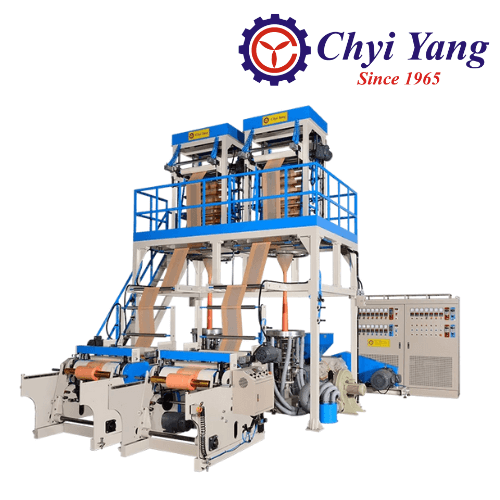

5-LAYER CO-EXTRUSION BLOWN FILM MACHINE

カテゴリー : 共押出ブロー成形機

CHYIYANG specializes in manufacturing 5-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

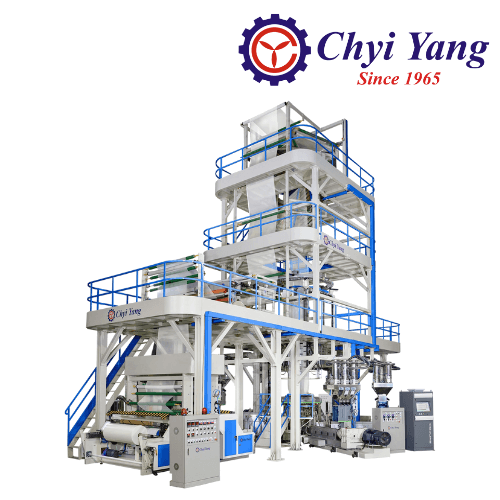

ABA 3-Layer Co-Extrusion

カテゴリー : 共押出ブロー成形機

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.

高速PPブローフィルムマシン

カテゴリー : ブローンフィルム押出機

MONO-LAYER-HDPE-LDPE-MLDPE-PP高速PPブローフィルムマシン特殊なスクリューミキシング設計により、優れた均一性と高出力が得られますダイとエアリングが大幅に改善され、フィルムの均一性、引張強度、安定性を提供します。ギアボックスは、高トルクと強制潤滑システムを使用して、機械のダウンタイムを最小限に抑えます

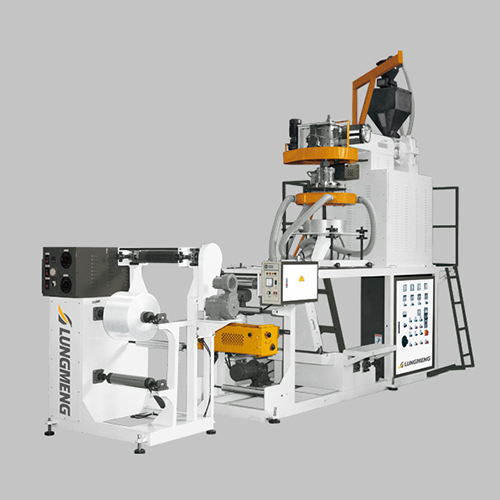

振動ホールオフユニットを備えたブローフィルムマシン

カテゴリー : ブローンフィルム押出機

単層HDPE / LDPE / MLDPE / PPブローフィルムマシン、振動ホールオフユニット押出機2層HDPE / LDPE / MLDPE / PP