Rigid Sheet Extrusion Line

カテゴリー : フィルム・シート用押出ライン

1. Extruder is driven by AC Inverter duty motor, with excellent efficiency and lowest power consumption. 2. Extruder hopper with low-level sensor work with auto-feeder will keep material in stable supply. 3. Hydraulic driven screen changer avoid any particle goes to melting pump & flat-die. 4. Melting pump with accurate rotation control, keeps the material flow stable. 5. Extruder & melting pump speed is working on pressure synchronized controlling system.

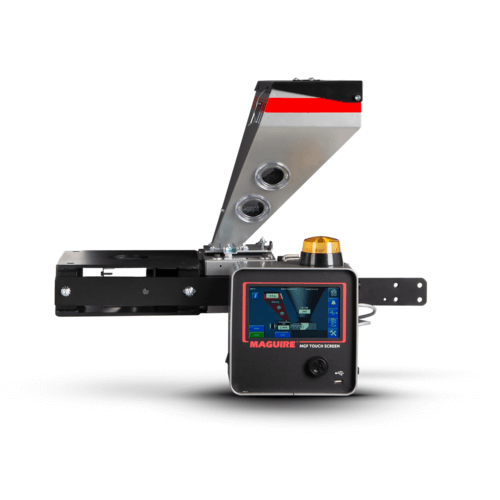

MGF Gravimetric Feeders

カテゴリー : 測定機器

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy. Unique twin load cell technology Dosing accuracy ± 0.2% on 1% setting Feeder ideal for all molding and extrusion processes

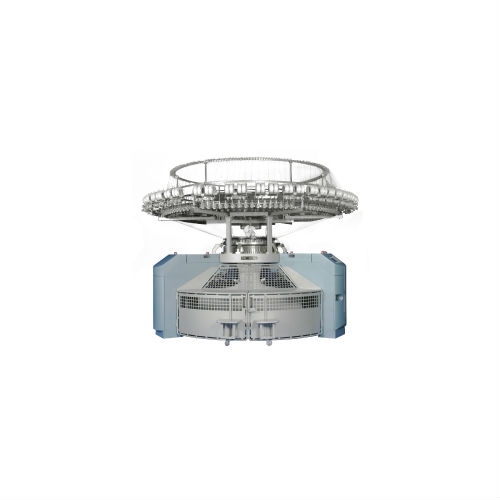

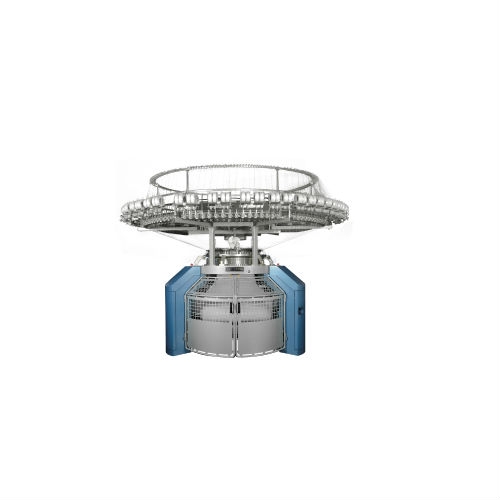

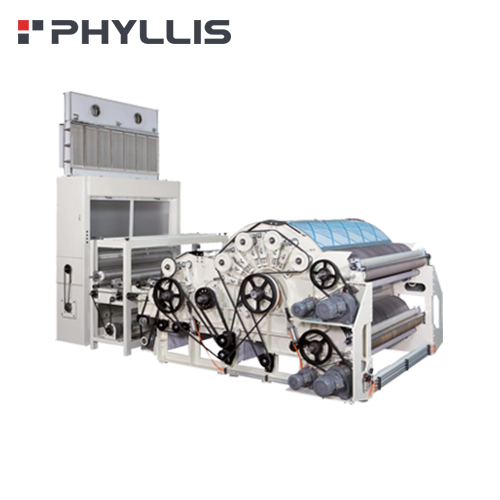

カーディングセクション

カテゴリー : 不織布生産ライン

ファイバープリオープナー、ブレンドビン、ファインオープナー、ホッパーフィーダー、ウェイトパン、カーディングマシン、クロスラッパーおよびその他の周辺機器を含む完全なカーディングセクション。テイラーは顧客のニーズに応じて完全なカーディングラインを作成し、生産の大きな柔軟性につながります

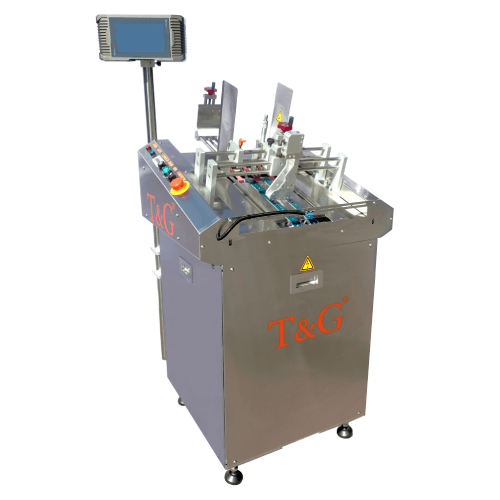

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS FLUSHING

カテゴリー : 中空包装機

Automatic Tray Sealer with Vacuum and Gas Flushing from Jaw Feng Machinery Co., Ltd. is made of stainless steel. Outdoor security vacuum cover. When electrical box is opened, it will shut down immediately. Can use multiple die sets and easy to change over, Multi-lingual PLC touch screen with a movable arm. Operate 360°. Every functions on the screen are presented in narrative, simple to understand. Vacuum / nitrogen, vacuum / skin pack, and sealed packaging. Offering lots of models to meet different sizes of trays. Able to work with date injecting, date thermal printing, labeling, aligner feeder, etc.

自動給餌および分割機AFC-700

カテゴリー : カッティングマシン

Special feeder mechanism will not cause scrape or daamge to materials, to ensure 100% productivity of stisfactory products. Feed length and feed speed can be programmed to suit different properties of materials, so it has high flexibility in production. Simple and easy operation interface with touch-control monitor to expedite personnel training. Automatic recoiling mechanism, with the design of electronic control, to enable one-man one-machine operation. Feeder with servo control to ensure accurate feeding dimensions, and take precise control of material costs.