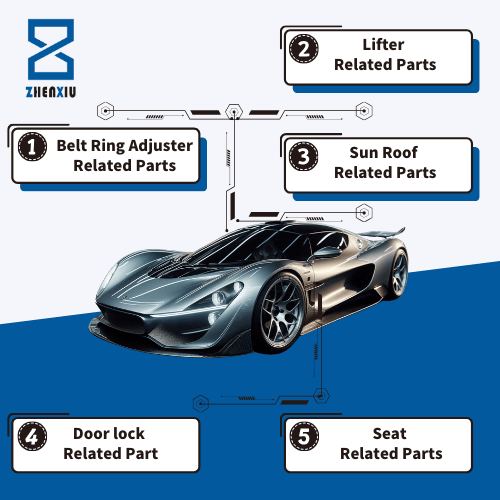

Door lock Related Part

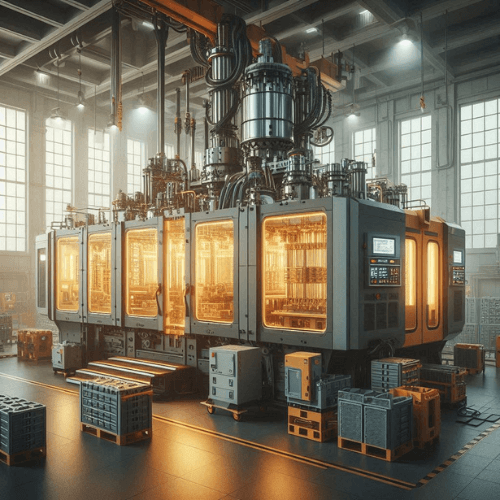

This product is made of PP+GF (Glass Fiber Reinforced Polypropylene), offering high strength, impact resistance, heat resistance, and low deformation rate, ensuring the stability and durability of large panels and main boards in high-load environments. It is designed for applications in structural support, industrial equipment, and automotive interior and exterior components, delivering excellent mechanical performance and long-term stability. Manufactured using a 1600-ton large injection molding machine, this product enables the production of large-sized, high-precision plastic components, ensuring superior structural rigidity and consistency to meet various large-component requirements. Additionally, compared to metal parts, PP+GF provides both high strength and lightweight advantages, effectively reducing product weight.

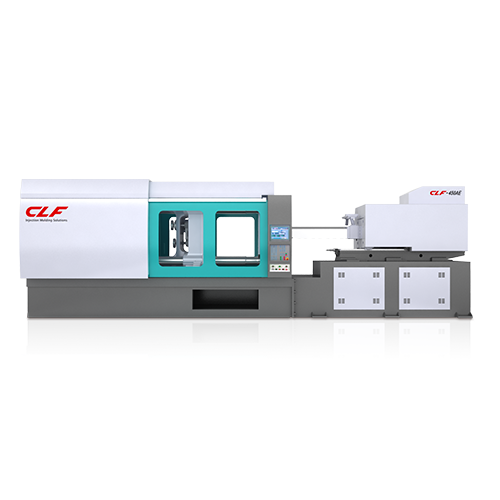

AEシリーズ - 全電動プラスチック射出成形機

カテゴリー : 電動射出成形機

長年にわたり日本とODMの協力が成功し、高速、正確、省エネ機能を備えた、全電動射出成形機の新世代を開発し、OEM / CLF会社、蓄積された無数の技術を経験して守ります。ドイツのシーメンスの制御システム、他のシステムに勝る利点...

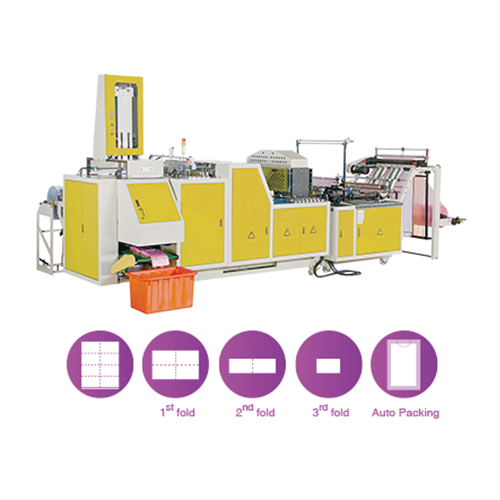

ツインライン高速Tシャツ製袋機(ホットカット方式)+自動包装システムTPFA-V + AP

カテゴリー : 用途別製袋機

自動梱包ソリューション - 自動梱包ソリューションにより、収集の労力をさらに節約できます。完成したパイルは、印刷された外袋によって個別に自動包装されます。利用可能なカスタマイズされたソリューション 高速ホットカットシステム - プリントTシャツバッグ用。フォトセルとサーボが正確な印刷位置を登録します。 200/250/300rpmの高速ホットカットシステム。 ツインサーボシステム - 印刷見当付きの2つのラインを正確に制御する2つのサーボ。

全自動高速カッティング&シーリング、3折り、パッキングマシン

カテゴリー : シーリング機械

サーボモーター制御による全自動高速カッティング&シーリング、3折り、パッキングマシン。 ‧シールと切断、3つの折りたたみ、自動梱包。 ‧コンピューター化されたヒューマンタッチスクリーンコントロール、簡単な操作。

85-150 ton injection molding machine product

カテゴリー : 射出成形製品

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

Manufacture of automobile parts and accessories

カテゴリー : 射出成形製品

ZHEN XIU Plastic Enterprise Co., LTD specializes in manufacturing injection-molded components for electronics, home appliances, automotive, and motorcycle parts. With a 600-ping production facility and 17 injection molding machines of varying tonnage, the company has been a trusted OEM partner for major automotive and motorcycle component manufacturers since 1986. Its products have successfully entered markets in Asia and the Americas, backed by ISO 9001:2015 certification for quality management.

DESIGN AND DEVELOPMENT PARTNER

カテゴリー : 射出成形用金型

JDM / ODM SERVICES When bringing a new product to market or re-launching an existing product with new features, key success metrics are quality and timing t o market. Either or both may be negatively impacted if the design proves difficult to manufacture especially if there is a rapid demand for increased volume. A design partner who is well integrated with a full service manufacturing system knows how to minimize risk. Our design teams have executed numerous design-build projects for customers across a variety of industries on a global scale. We incorporate manufacturability, assembly and test principles into the EDI-early design stages involved of a product to assure seamless production. JDM/ODM services include : To use the PLM system to monitor the product life cycle management. Concept Development Mechanical Drawing Layout Documentation Verification Material Management & Sourcing Rapid Prototyping & Soft Tooling Initial Pilot Builds & DFM αTest /βTest/ Burn-in Tooling & molding in house Final Assembly Following the design phase of your product, we build prototypes to test the DFM manufacturablity and any industry compliances. Prototyping may occur multiple times at various points in the design and planning stages for a project. Once all the design and manufacturing issues are worked out, we can rapidly transition into full-scale production. Please visit our Contract Assembly page to learn more about our assembly facilities. OEM Our Original Equipment Manufacturer (OEM) service is responsible for designing and building a product according to a customer’s own specifications. Our service also includes & DFM,EDI,3D printer rapid prototype global distribution and returned product factory repair, which can greatly reduce customer’s overall production costs.

プラスチック頭部基(逆止弁)

カテゴリー : バルブ

最も重要な部分の一つを形成するプラスチック製ヘッドショットグループ、我々はプラスチック製のプラスチック製のヘッド・グループのすべての種類を提供します。開発や製品のさまざまな形態に合わせたプラスチックによって。噴霧、スプレーまたはPVDコーティングの製品と他の人が非常に完全なパッケージを持っているかどうか。