NAN YUN: Professional in Design and Manufacture of Large Screws and Barrels

Established in 1993, NAN YUN Industrial Co., Ltd. specializes in the design and manufacture of full series of screws and barrels. NAN YUN has an engineer's design team with outstanding theoretical background and practical experience, hence they are able to design high-output and high-performance products as required by customers, and also use Computer Numerical Control (CNC) equipment to manufacture products that satisfy customers.

Why to Use Recycled Plastic Pellets for Injection Molding instead of Regrinds?

Using recycled plastic pellets for injection molding brings several benefits to businesses as well as to the environment. These can be listed as reducing waste, conserving resources, saving material costs, improving sustainability, and creating positive public relations. Recycling injection molding manufacturing wastes is one of the fastest ways of generating recycled plastic for injection molding. On the other hand, using recycled plastics in injection molding in pellets form is also found superior to regrind form by many injection molding manufacturers.

HCI: How to Rewind an Ellipse Shaped Product - Dare to Try Automated Process Solutions - Ellipse Shaped Reel Rewinder

A reputed professional filter manufacturer in Taiwan contacted HCI. They specialize in the production of corrugated axial air filters, and have obtained many patents in Taiwan, China, Japan, Germany and the USA. However, it encountered great difficulties in the rewinding process, because the finish product is an ellipse shaped reel. That's right, it is an [ellipse] rather than a round product that we are familiar with. At present, customers can only rely on manual equipment for several stages of production. Not only the production capacity is low, and not able to improve the yield rate.

Cosmo: A professional manufacturer of plastic bag making machines

COSMO MACHINERY CO., LTD. has been founded in 2001 in Taiwan. Based on more than 20 years of designing and manufacturing experience, with ISO 9001 and CE standard, COSMO has been well-known as a professional manufacturer of plastic bag making machines from Taiwan. Up to now, we have extensively exported 3000 machines to 100 countries spreading all over the world.

PRM-TAIWAN Wishes Happy Republic Day to Our Indian Friends!

PRM wishes Happy 74th Republic Day to our valued platform users from India in advance. PRM would like to thank all our Indian friends for all your love and support ever since our platform was established.

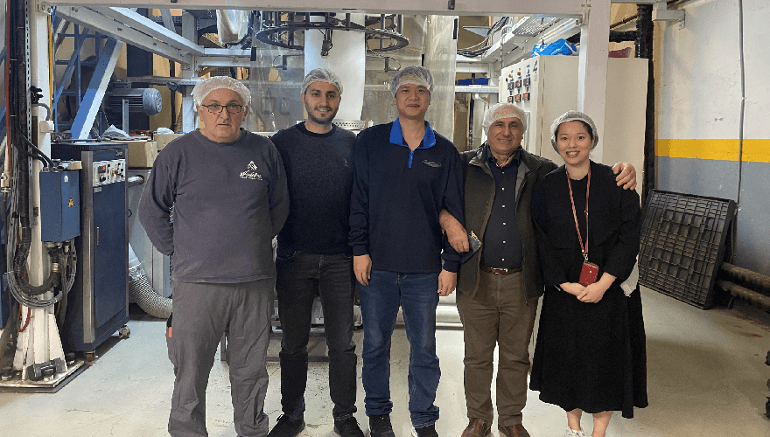

JANDI’S: The Strength of JANDI’S with Successful Case Sharing

Mr. Samet AYDOGAN is the Export Director of AYDOĞAN Plastik which is based in Turkey. AYDOĞAN has been in the flexible packaging sector since 1988. They are a tailor-made producer who is addressing almost all sectors, starting from food, personal & home cares to textile and many others. As a tailor-made producer, they have to make all the choices available for their clients, and that is why they chose JANDI’S, we make their requirements come true!

How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, and, most importantly, invest in a reliable plastic recycling machine.

CHAO WEI: Fully Automatic Perforating Draw Tape Bag On Roll Making Machine

CW-1200PDR-SV series are coreless bags on roll making machine, mainly produce side sealed perforating draw tape bags on roll or bottom sealed bags on roll with 2 times folding by triangle folders. Machine is equipped with servo motors for stable and precise production, touch screens making bag length and speed settings simple and easy operation, German made photocell for bags with printing, German made E.P.C guiding system and servo controlled web auto tension for very smooth production.

A New Product From The FCS Multi-Component Injection Molding Machine Line Has Been Released: The Debuts Of The X-Type Parallel Quartet-Injection Molding Machine!

The multi-component molding technology solution of FCS Group (FCS) has embraced a new product: The X-type parallel quartet-injection molding machine. This technology has been introduced to the FCS large multi-component injection molding machine line. The first GW-1600R large two-platen multi-component injection molding machine (quartet-injection molding machine) has been delivered to a well-known Chinese automotive lamp supplier for mass production.

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.

BoReTech: How to Make Recycling Waste PET Bottles Easier and Produce High-Quality rPET?

The global brands announced they would give up using virgin plastics in their products, which means more recycled plastics and rPET is required in markets. More than 60 brands and retailers have set corresponding reduction targets on the use of virgin plastic. The new commitment proposes that by 2025, the absolute benefit of virgin plastic will be reduced by nearly 20% compared with 2018.

HSIN LONG: Leading Innovations in Multi-Layer Extrusion Dies to Achieve Sustainable Development Goals

K Trade Fair as the biggest and the most influential worldwide exhibition in the Plastics & Rubber Industry has been hotly held from 19 to 26 October. There is no doubt that everyone has already been waiting too long for this extravaganza especially after the effects of the COVID-19. HSIN LONG is no exception, bringing their newly innovated Multi-Layer Blown Film Extrusion Die...

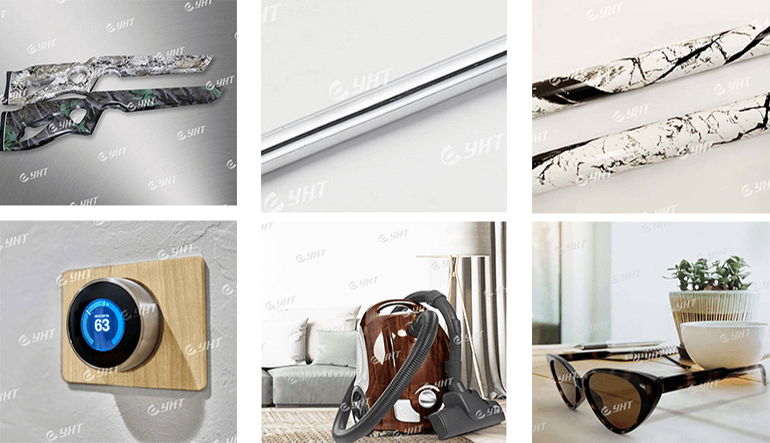

Yuan Heng Tai: New Technologies for Surface Decoration

Cubic Printing is a relatively recent Surface Decoration Technology. It is also known as hydro dipping or water transfer printing, and it is a method of applying a customized design to different materials such as glass, ceramic, metal, and plastic. They involve immersing an object with a print design in water.

5 Tips to Increase Efficiency in Plastic Recycling Process

In parallel with the increase in the consumption of plastics, driven by economic development and population growth, global plastic waste is projected to triple by 2060 based on OECD reports. Increasing plastic recycling efficiency is one of the major keys to returning more plastic waste to production lines as a valuable recycled polymer. Here we have listed 5 tips to increase efficiency in the plastic recycling process.

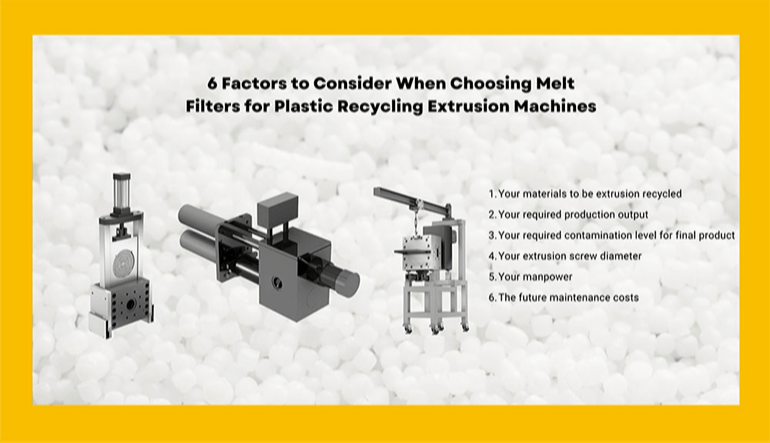

GENIUS: What to Consider When Choosing Melt Filters for Plastic Recycling Machines?

Melt Filter is an important component of Plastic Recycling Extrusion Machine. It helps to improve the end product's quality while also increasing production. However, as you are aware, not all melt filters for recycling and filtering post-consumer and post-industrial plastics are the same. They differ in terms of performance and price. If you want to buy an optimal melt filter for your plastic recycling extrusion machine, you should think about various variables before making your final decision. In this article, we will discuss 6 critical aspects that will assist you...

TwinScrew’s Bioplastic Solutions Enhance the Carbon Emission-lowering Efficiency

The plastics industry is undergoing critical transformation to achieve the goal of net zero defined in UNFCCC. It is generally accepted that increase in reuse, reduction and recycling are essential actions. However, the latest annual recycling rate is 9% and only 40% of the recycled plastic wastes went to the products though the European area leads the world in awareness of environmental sustainability and recycling infrastructures.

K Show 2022 -Recycling for Post-consumer and Post-industrial Plastics on the Rise

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste.

Yuan Heng Tai: How to Treat Different Materials for Hydro Dipping? Point to Take into Consideration.

Can I do water transfer printing on my own clothing? My car interior? Or exterior? My shoes? My nails? Pet’s food plate? Beverage plastic bottles? Cosmetic box? No doubt we can list thousands of materials or products, however, some of them cannot be decorated or not properly decorated by water transfer printing. So, you may ask, how can I know what products or materials can be dipped, and what cannot be dipped?

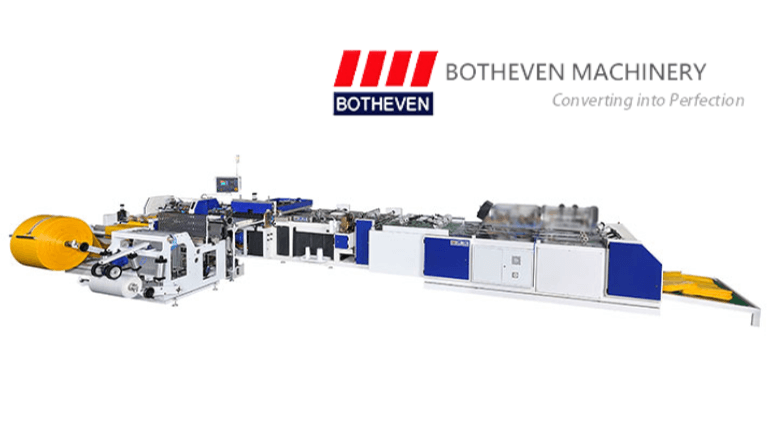

Botheven, Ready to Showcase Innovation and New Developments During K 2022

After 3 years of forth and coming due pandemic full of new challenges, the biggest exhibition in the plastics and rubber industry is just around the corner. Many manufacturers are presenting the hard work they have put into new technologies during these 3 years, always have better performance and quality options for customers around the world.

WEBCONTROL: The Most Advanced Seaming Machine - K2 Plus

Webcontrol innovates the new generation of seaming machine, PLUS series, the most advanced seamer in the industry. This new design offers friendly operations, facilitating training with the most automated machine on the market. K2 Plus is an entry model for shrink sleeve converting. Fastest set-up with the lowest waste is a great point for easy operation.

TAIWAN KINKI: All Electric Vertical Injection Molding Machine, Fits Topics of K 2022

K as one of the biggest Plastics and Rubber international exhibitions which is held every three years, kicked off from 19 to 26 October 2022. K has announced this year’s topics: Circular Economy, Digitalisation and Climate Protection, which are recent global hot topics which every industry is working hard on.

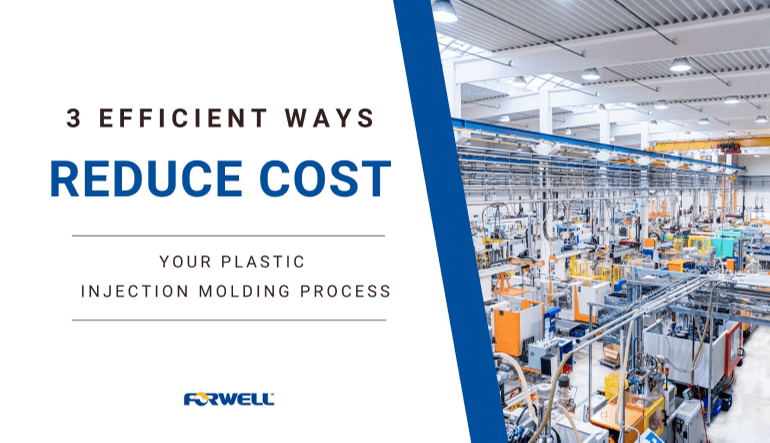

3 Efficient Ways to Reduce Injection Molding Cost

There are many things that you can do to cut costs in the plastic injection molding process. The truth is that reducing cost is a complicated process and requires a lot of time and effort to reduce a large number of your costs. Many companies handle cost cutting in different ways. Below, we have listed 3 of the most efficient ways to reduce cost in your plastic injection molding process and we will also be your guide to outline just how your choice of quick-mold change system could result in differentiating your project cost.

KANG CHYAU: New Generation, New Prospect in Plastic Converting Industry

Kang Chyau has always been a leader in the field of Blown Film Machinery, not to mention how satisfying it is in terms of customization. The times are progressing and technology is innovating. This company with about 35 years of technology and experience has never neglected its pace. At the K-show exhibition this year, Kang Chyau is promoting the 3-layer blown film model: KMTL-55-65-55 E3.

SHINI: Advantages of Central Conveying System

In the 21st century, modernization and scientific and technological development push forward the plastics industry chain's growth, and a systematic centralized conveying system has been widely deployed in injection moulding workshops of various products. It can realize the centralized processing materials and meet various unique demands such as conveying, dehumidifying...