Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

UHS Turret Slitter Rewinder - UHS-TR | WEBCONTROL

UHS Turret slitter rewinder The UHS-TR model is a proven fully automatic slitter rewinder, offered with many options to fulfill even the most demanding applications: - Cutting-edge slitting systems - Reliable auto cut and transfer - Advanced tension control - Combined with progressive differential winding technology - Precision and capacity at an affordable cost. - UHS-TR a must addition to any plant requiring quality Automatic knife positioning down to 25 mm slit width, double turret unwind, automated finished roll unloading systems are some of the available options to increase productivity, quality and decreasing operator influenced down time. Materials to be processed: Plastic film, paper and laminates Thickness range: -Rigid films: 10 – 200 micron -Soft films: 12 – 300 micron Machine Specification - SLIT UHS TURRET: -Web width:1300 / 1600 mm max -Unwind roll diameter: 1000 mm -Unwind roll weight: 1500 kg -Unwind roll cores: 3” and 6” I.D. -Finished roll diameter: 610 mm max -Finished roll cores: 3” and 6” I.D. -Slit width: 50 mm and up -Machine speed max: 600 m/min (depending on material type/quality) -Winding tension: 0.5 pli to 2.5 pli (11 - 45 kg) standard

SIAF 2021 Guangzhou Exhibition Opens Door | PRM-TAIWAN

【 PRM-TAIWAN on SIAF Guangzhou 2021 Exhibition 】 Info: Great news for PRM-TAIWAN, Taiwanese Suppliers, and all the buyers who have put their trust in us! Despite COVID-19, we are glad to announce that thanks to our branch office in China, PRM has come back to the international exhibition ground to do what we do best - Provide professional services to international buyers! PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/377P7Vv To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our Social Media Channels: PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

Quick Mold Change | FORWELL

Quick Mold Change - Quick Mold Change System-forwell-qmcs-en-Forwell Features • Decreased mold change time • Fully customizable to fit a wide range of machines • Safer operations • Reduced labor costs • Easy changeover for small batch runs System Introduction : Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

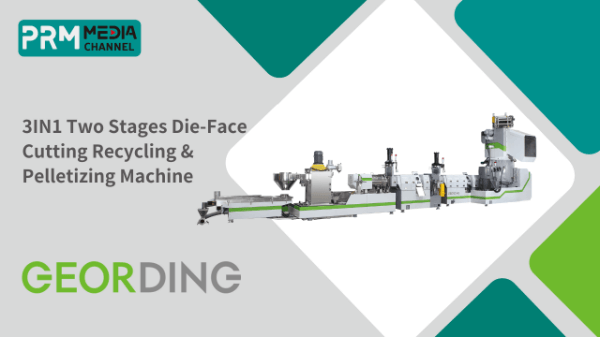

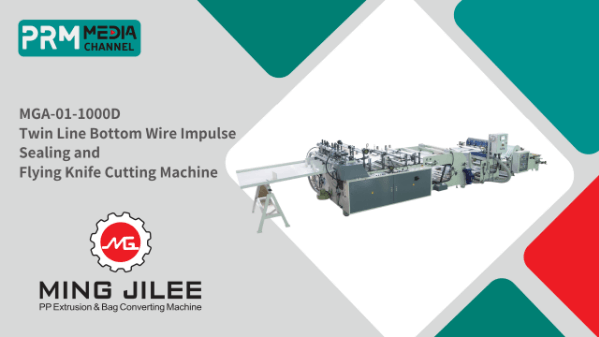

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

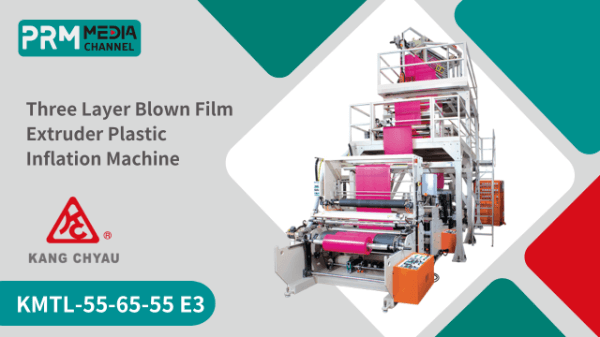

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap. Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3 Film Width: 500-1800 mm Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

Packaging Industry Trends and Obstacles | PRM What to Say EP5

In the fifth episode of the PRM What to Say program we interview Ms. Wang, the Chairperson of Taiwan Packaging Association. Through the interview that our team member Sunny held, we touched several current topics related to the packaging industry, online and physical trade shows, food food safety, shelf life and modern packaging designs, the association’s support for the members and so on. Since the beginning of the outbreak many machinery industries are facing several common obstacles such as logistics, machinery installation and maintenance. For the many machinery categories, the demands are suspended. However, for the packaging industry, the situation is more specific. Due to the global lock downs, the housing economy has been revived and the needs for food packaging and cargo packaging boomed. On the other hand, the machine manufacturers are still facing the common obstacles of the pandemic to reach out to their customers.

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

Exploring the Future of Plastics Industry with Juan Eduardo Zarate | 2025 PLASTIMAGEN Interview

What’s next for the plastics industry? At 2025 PLASTIMAGEN, PRM-Taiwan interviews Juan Eduardo Zarate to uncover key insights into this year’s exhibition! Interview Highlights: How big is PLASTIMAGEN 2025? Discover the scale and number of exhibitors at this leading plastics event. Celebrating 25 Years: Special activities marking the 25th anniversary of PLASTIMAGEN! ESG & Sustainability: Plastics remain essential—how can we improve recycling and promote sustainability? ???? Subscribe to PRM-Taiwan for exclusive industry insights!

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.