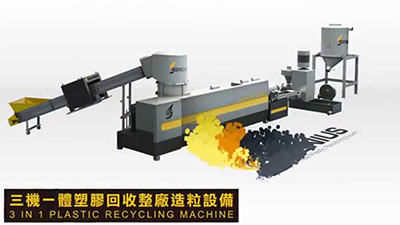

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

ChenHsong CFO Dave:Technology Innovations and Market Insights in Turkey | PlastEurasia Istanbul 2024

At PlastEurasia Istanbul 2024, ChenHsong CFO Dave discusses the company’s long-standing presence in the Turkish market and their latest technological innovations. Dave shares insights on the newest machines domestrate at the event and offers expert views on market direction and industry trends, particularly in the Turkish and regional plastics markets. Watch to learn about ChenHsong's cutting-edge technology and the future of the industry. Like, share, and subscribe for more industry insights!

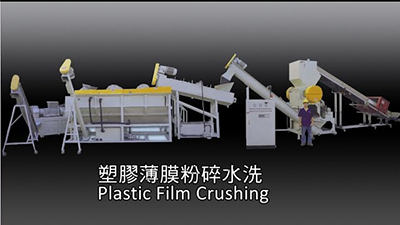

Plastic Washing Machine | GEORDING

Plastic Washing Machine - Plastic Film Crushing Washing and 3IN1 Pelletizing Line - Waste Plastic Crushing & Washing Line 1000kg - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of Plastic Washing Machine. The main businesses include: Plastic Washing Machine and planning of entire plant’s equipment. While the demand for output and quality in Plastic Washing Machine worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Plastic Washing Machine products and services to higher standards.

Bag Making Automation Solutions at K 2022 | PLAS ALLIANCE

It's such a great honor to interview Eugene Chiu, the Sales Manager from PLAS ALLIANCE LTD. In the interview, he mentioned influences by the pandemic. In the end, he also talked about the trending topics in recent years, for instance, Circular Economy. PLAS ALLIANCE LTD. also has excellent customization ability. They provide customized machinery, especially when their customers are searching for Biodegradable Materials applications.

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Multi-layers Die Head Manufacturer at K 2022 | HSIN LONG

Hsin Long Thread Rolling Machine Co., Ltd. is knowing for high-quality products, such as blown film machine, extrusion die and extruder filter, and their post-sale service. By interviewing Ms. Sandy Chen, Production Manager, we gained the information about how Hsin Long apply digitalization in their equipment.

2024 CHINAPLAS Interview | ANIPAC

It’s our great honor to interview Mr. Aldimir Torres Arenas from ANIPAC He shared his insight for the China and Mexico market. Check our video for more information!

2022 Intelligent Asia - Automation Intelligence and Robot | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be amazed how automation intelligence and robots applied in machinery to improve the efficiency and production. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

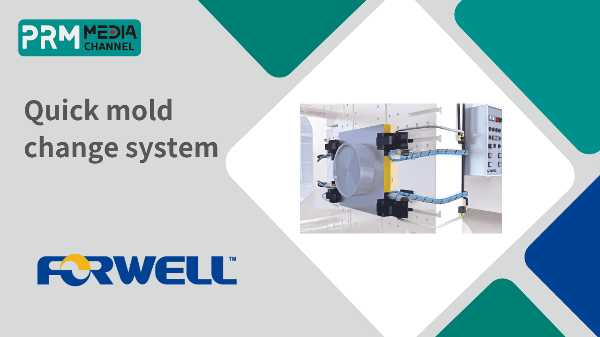

Quick mold change system|QMCS|for Injection molding|Sistemas de cambio rápido del molde|FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations. When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits. Indirect Benefits Die Standardization Press Standardization Increased Safety Improved Working Environment Increased Competitiveness Direct Benefits Reduction in Die Change Time Efficient Small Batch Runs Reduced Stock Handling Higher Productivity and Quality Reduction in Labor Costs

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6 Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event PRM Theme Pavilion, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry. Let's take a look at the PRM What to Say episode 6, where we are evaluating and introducing the next PRM Theme Pavilion which focuses on the Packaging industry. In the video, you will learn more about not only what this event is about, but also the benefit of the event for global visitors, how the event is planned and concentrated on a specific focus with the selected machine manufacturers and machinery lines that a packaging business all need.

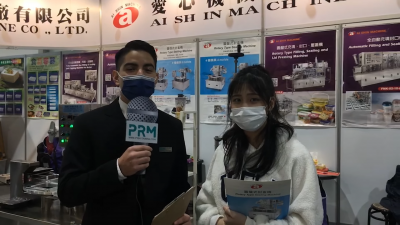

Food Packaging Solutions | AI SHIN Interview

At the recent TAIPEI PACK exhibition, PRM Media Channel had an interview with AI SHIN MACHINE CO., LTD. to discuss about the current situations in the packaging industry, upgrade in the service of the company due to current pandemic, also the machinery showcased. AI SHIN is famous for its Automatic Filling & Sealing Packing Machines. The company specialized in manufacturing high speed packing machines for food, filling and sealing liquid cups such as yogurt, juice and water cups. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for the similar videos!~ MAIN PRODUCTS/SERVICES OF AI SHIN: Automatic Filling Machine, Automatic Sealing Machine, Rotary Type Filling Machine, Filling & Sealing Machine, Bag Sealing Machines, Sealing & Packing Machines, Semi-automatic Sealer, Rotary Type Sealing Machine, Fully Automatic Box Filing & Sealing Machine for Butter, Capping Machine for Butter, Yogurt Packaging Machine, Pudding Filling & Sealing Machine, Frozen Food Filling & Sealing Machine, Cup/Bowl Instant Noodle Packing Machine, Packing Machinery, Cap Sealing Machine, Jam Cap Sealing Machine, Butter Filling/Sealing Machine, Cup Filling Sealing Machine ***