Interleaved Draw Tape Bag On Roll Converting System ft. Labeling Device | LUNGMENG

【Feature】 High-speed servo-driven system Special sealing system, keeping the production speed steady regardless of the film thickness and length Convenient sealing knife system, with easy changeovers of sealing knives, making production more flexible Unique perforating knife system for various film materials Intellectual rotary interleaved winder with the 2-in-1 system applicable to bags on roll and interleaved bags User friendly touch screen control system Reliable & multi-functional system, capable of producing star sealed bags, wave type bags, table covers and many more through modular system changes 【Company Introduction】 Lung Meng Machinery also known as Dragon Plastic Machinery was established in 1976 as a professional plastics converting machinery manufacturer. In 1983 Dragon Plastic developed “All In Line System”, which allows blown film extruders, printers and bag machines to work together in-line. Lung Meng Machinery's wide range of innovative machines are the very solution to exceed customer's expectation at a satisfactory price. After 46 years of continuous research and development, Dragon Plastic has become the only company that can integrate all three kinds of machines together in an in-line process.

2024 NPE Interview | NPE The Plastics Show

We at NPE invited PLASTICS Marketing Director Damaris to be interviewed by us. Sharing the latest news at the 2024NPE exhibition, there were 50,000 visitors on the third day of the exhibition. This is something very happy about.

Plastic Blow Molding Process Explained | PRM What to Say EP 13

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding. In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method. For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often. The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

Crystallized Hopper Dryer(PET Crystallizer) - Engliish Subtitle | Yann Bang

The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time.

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

PRM Buyer Guide | PRM-TAIWAN

We have over 200 of the biggest and many of the small and medium-sized Taiwanese machinery manufacturers on our site and contacts with many more. Whether you are looking for full lines such as recycling machines extruders, blow molding machines, injection molding machines and printing machines, or auxiliary equipment and parts such as gearboxes, barrels, screws, molds, dies, control systems, and virtually anything related to the plastic and rubber industries including packaging. If it’s made in Taiwan, we will find it for you!

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

Screws / Barrels for Extrusion and Injection Molding | NAN YUN

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

MOLD TEMPERATURE CONTROLLER, YANN BANG

YANN BANG, Patented Mold Temperature Controller, Temperature Controlled Unit Our temperature control unit can use water/oil heating system to secure the high quality of plastic production made by injection, extrusion and blow molding machines. Learn more: https://www.yannbang.com/mold-tempera...

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

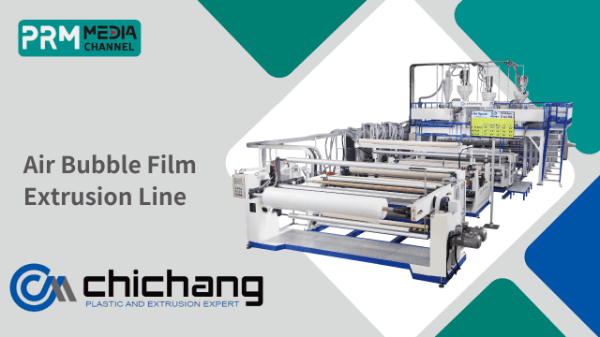

3 Layer Air Bubble Film Extrusion Line | CHI CHANG MACHINERY

【Applications】 The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope. 【Compnay Introduction】 Since our founding in 1972 CHI CHANG MACHINERY ENTERPRISE CO., LTD has been on a never-ending quest for breakthroughs and innovations in technology. CCM ensures that wherever our customers are in the world, all of our extrusion equipment and services reach outstanding levels of performance. Adhering to our motto of Integrity, Innovative technology and Sustainable services, CCM is dedicated to the design and fabrication of plastic extrusion machinery.

TaipeiPLAS 2022 Live | PRM x KAOLU x PIDC

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 9/30(Fri.) 15:00 (GMT+8) 【KaoLu Enterprise】 Kao Lu Enterprises Co. Ltd., established in 1980, has been dedicated to manufacturing and supplying premium quality pneumatic components such as valves, cylinders, and ancillary accessories. 【Plastics Industry Development Center | PIDC】 What's the key role that PIDC plays in Taiwan society and how they provide services to plastics manufacturers. By interviewing General Manager of Dr. Hsiao, he would share the insight of SDGs, 2050 Net Zero programme, and also provide advice to Taiwanese enterprises.

Quick Mold Change System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

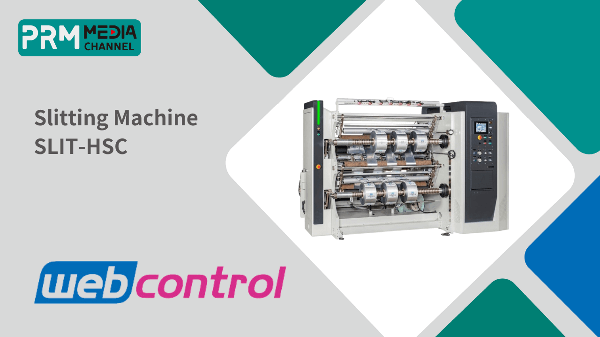

Slitting Machine SLIT-HSI 1600 | WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023! Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

2024 CHINAPLAS Interview | CHINAPLAS

We are here with Ms. Ada from the CHINAPLAS. She also shared very useful information about the forthcoming CHINAPLAS 2024 including the focus of the exhibition.

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

3000 Ton Plastic Injection Moulding Machine | CLF

3000 Ton Plastic Injection Moulding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

Slitting Machine (HS-Compact) | WEBCONTROL

The SLIT-HSC series slitter is new compact type to save the working space. From the unwind side, the web is guided middle to the main machine, easy access to the slitting section and eliminates dust collection/hazarded steps. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MNI touch screen. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

T-Shirt Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines T-shirt bag on roll making machine High production efficiency to save men power and time Computer control over the entire process From film roll to final bag, once process flow Servo motor, as standard attachment, makes it easy to adjust the bag length and production speed Automatic film feeding, coordination free from tension adjustment Oscillation film feeding system for stability and high out put Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses Automatically core changing system Punch system on magnetic roller 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Inspection Rewinding Machine| WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-WEBCONTROL Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

Plastic Recycling in Japanese Market at K 2022 | POLYSTAR

We were glad to have an interview with Mr. Kenji Murai, agent of POLSTAR in Japan, who shared his observation of plastic recycling in the Japanese market and his experience doing machinery business.

PRM at SINO PACK 2021 | Packaging Machinery & Materials Exhibition

Last week we attended our 2nd International Exhibition of 2021 and all thanks to our Marketing Team of PRM Shenzhen Branch!! Sino-Pack 2021 Exhibition on its 27th Edition, which was held by ADSALE, the same organizer of CHINAPLAS. The exhibition included: + Plastic packaging manufacturing machinery + Automated smart packaging machinery + And related machinery. To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our B2B Platform & Social Media Channels: PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/3cdtMfF PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

Air Bubble Film Extrusion Line - CHI CHANG

Air Bubble Film Extrusion Line - 2.5M Wide 3-layer Air Bubble Sheet Extrusion Line The 2.5M Wide, 3-layer Air Bubble Sheet Extrusion Line produced by Chi Chang Machinery Enterprise Co.,LTD has excellent quality and an outstanding reputation. The Air Bubble Film Extrusion Line includes Take-off unit & winder, In-line lamination, T-Die & laminating unit and EPS/EPE reclaim system.

Thermoforming Systems at K 2022 | ILLIG

It was a great honor for PRM to interview the Sales Director — Adam Liang from ILLIG. ILLIG showcased their newest Thermoforming Machine at K 2022. Integrated Sustainability and Digitalization into product applications, including recyclable and biodegradable PP flakes. Mr. Liang also shared his insights for the future in the Plastic & Rubber industry.

Temperature Control & Cooling Units at K 2022 | TOOL-TEMP

It's PRM's honor to interview Jasmine Koller, CEO of Tool-Temp AG, and Allen Tsai, General Manager (Taiwan), which gave us insightful sharing about their products and perception of K 2022 and of the post-pandemic era.

Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

Solventless Lamination - Webcontrol

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.

Plastics Industry Innovation Forum 2023 | PIIF

【主題論壇】 高值前瞻永續 產業創新應用 -塑膠材料躍升高值醫材的寶貴經驗、挑戰與未來展望 -塑膠材料跨入前瞻航太並前進外太空產業的實踐歷程與未來展望 -塑膠材料落實低碳排放及循環再生的永續生活應用 主持人:塑膠中心 蕭耀貴 總經理 與談人: 普瑞博生技(股)公司 陳彥文 董事長 漢翔航空工業(股)公司 莊秀美 副總經理 益材科技(股)公司 翁冠群 董事長 金元福包裝企業(股)公司 郭哲宏 總經理

Analysis of the impact of Low VOC anti-corrosion coatings on emission reduction | PIIF

Low VOC防蝕塗料於減排之影響分析 講者:漢翔航空工業(股)公司 工程處結構分析組 謝福湧 組長

Complete Set of Mixing Metering & Conveying Equipment | CHIAO WEI

【Machine Features】 A mixing system is a process of mixing raw plastic materials in particles or powders to manufacture piping and tubing structures. It is a part of the plastic extrusion process. It involves the pre-mixing of multiple additives, which is performed in an efficient manner. Mixing System is commonly used in manufacturing water pipes, plastic floors, wall panels, plastic floor tiles, wires, cables, plastic steel doors, windows, to name a few. Suitable for filling small amounts of additive. A semi-automatic operation system that saves labor and times, lowers production costs while upgrading throughput by 20%. With material storing function. No powder leakage during delivery. A mixing and delivery system that meets environmental protection requirements. The flow guide plate is a special design, featuring uniform mixing, high speed, superior dispersion and energy saving. Exclusively designed material outlet port can be set according to customer's material types. Another benefit is its fast material outfeed with residuals.(Patented design). The tank invertor is a stainless steel construction, polished to upgrade material missing efficiency and reduce electricity consumption. The steel base is a one-piece fabrication and equipped with anti-vibration pads, providing smooth and stable running. 【Company Intro】 "CHIAO WEI MECHANIC CO., LTD" founded in 1987 and a professional manufacturer of Hi-speed mixer, Blending machine & those ancillary equipments etc. Although we have established about twenty years, our staffs were continued and guided by principle of innovating, persuing the excellence & hard-working etc., Especially, the scientic-technology will be upgraded gradually as well as human life be diversified day by day. Since, our company has focused on new products R/D and manufactured hi-eff, automation, low noise & low pollution products. And we have contributed trivial efforts to make capability advances for professional.