- The output is 50%~80% higher (depends on the structure of fabric) than tradition model (SR series).

- SRC series could work with complete round(mono) yarn, flat yarn or fabric in mixed of both yarn.

- Adopt inverters or servo motors for machine control.

- The quality production and flexible application.

- Stable production speed.

- Simple operating and maintenance.

- Agriculture net, like Shade net, Anti hail net, Anti bird etc.

- Construction net, Building net, Barrier net.

- Packing net : Pallet net

- Fruit / Vegetable bag (L sewing type).

- Fencing net, Wind breaker.

| Model | SRC | ||

|---|---|---|---|

| Working Width | 170” | 210” | 252” |

| Gauge of Needle Bed | 6, 9, 12G/1” | ||

| Drive Bar (Total) | 2 ~ 8 | ||

| Yarn Feeding Roller | 2 ~ 4 units | ||

| Beam Feeding Bar | 2 ~ 6 | ||

| Main Motor W/Inverter | 7.5 HP | 10 HP | 10 HP |

| Power Consumption | 7.3 KW | 9.3 KW | 9.3 KW |

| Yarn Let Off System | Beam, Slitting & Extension Machine or Creel | ||

| Dimension L x W x H (mm) | 6,260 x 1,700 x 2,664 | 7,220 x 1,700 x 2,664 | 8,520 x 1,700 x 2,664 |

Remarks:

1.Special specifications are also available.

2.Manufacturer reserves the right to change the specifications without notice.

SRC series is single needle bed knitting machine which equips with compound needle system.

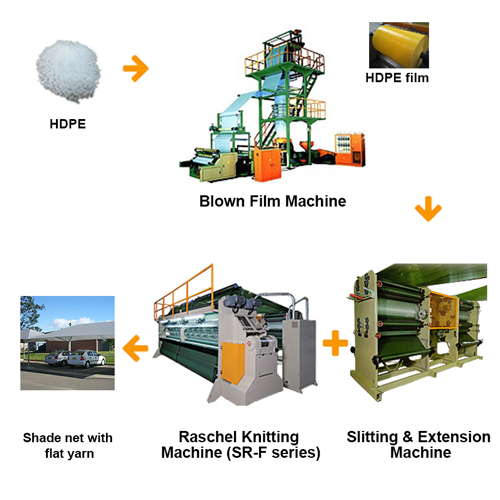

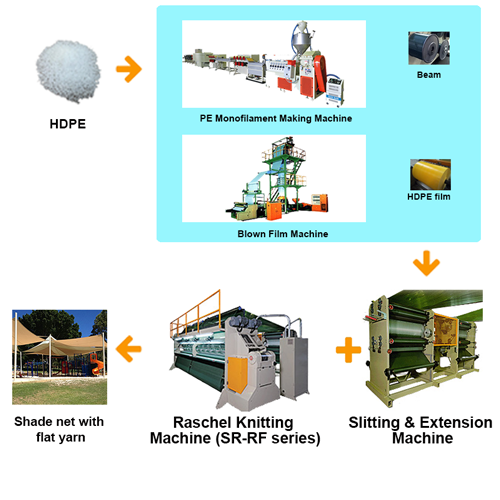

The output is 50%~80% higher (depends on the structure of fabric) than SR series. SRC series could have same yarn feeding system as SR series, which is able to work with beam or slitting and extension machine, so it could make the fabric with complete round(mono) yarn, flat yarn or mixed of both yarn.

The efficiency of knitting machine will be more than 10% if it matches slitting & extension machine compare with creel. Because of its steady yarn feeding, the machine can raise the quality of fabric also the waste rate is just half of creel type. But if customer had flat yarn or monofilament making machine already, we would offer creel system to work with machine.