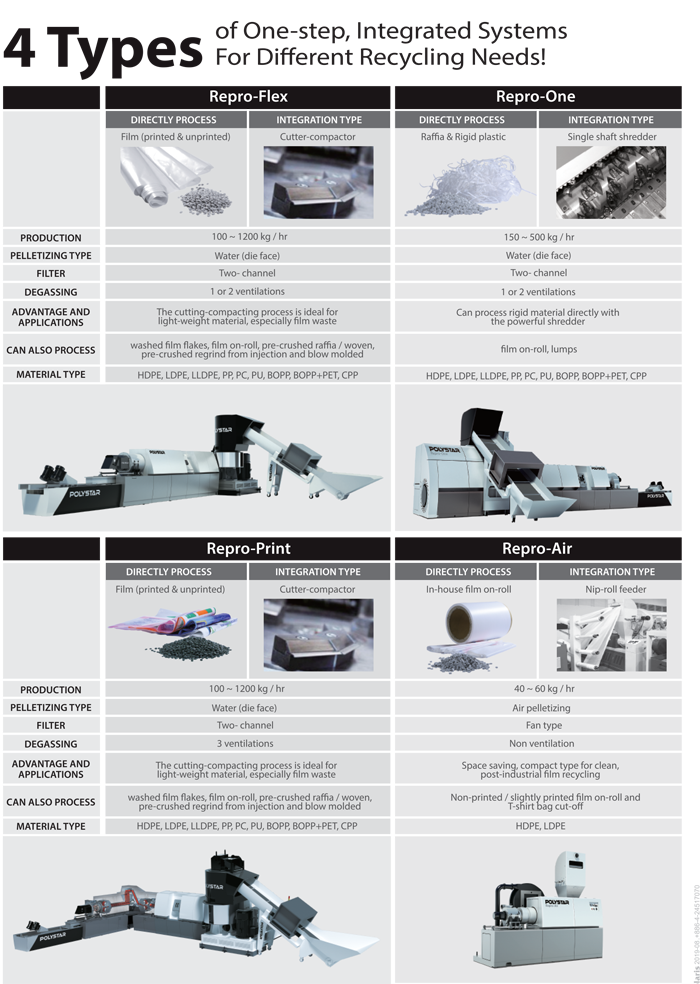

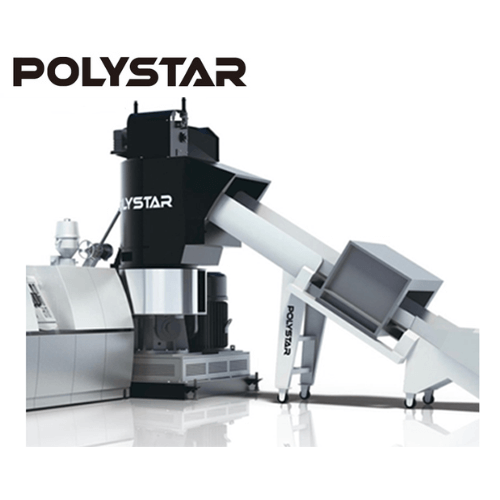

● ラフィアとフィルムの両方の廃棄物に最適

● 硬質廃プラスチックのリサイクルに適しています

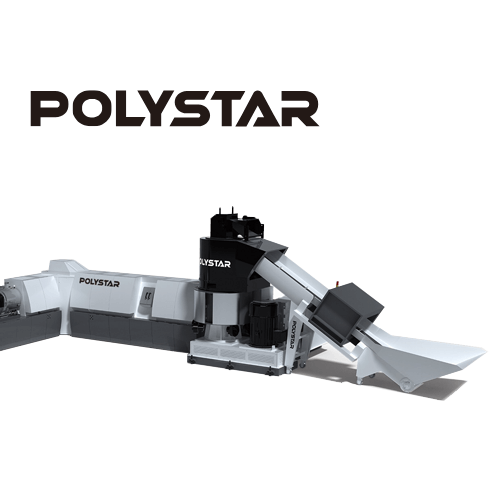

● シュレッダー統合された固体破砕済みリサイクルソリューション

● 環境保護のため真空ポンプに接続された高効率脱気

● ノンストップデュアルチャンネルピストン濾過システム

● 均一なペレット製造のための自動化ダイフェースペレタイジング技術

● インテリジェントな圧力検出および警報制御システム

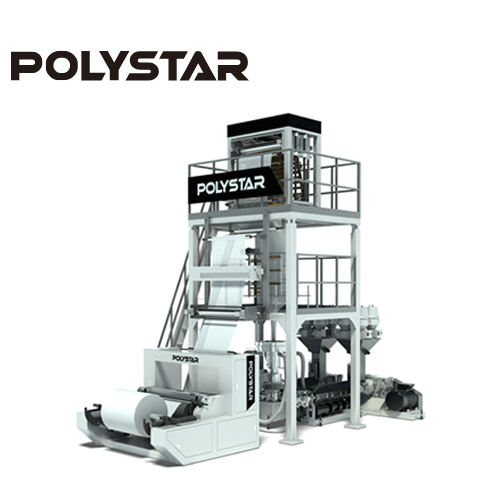

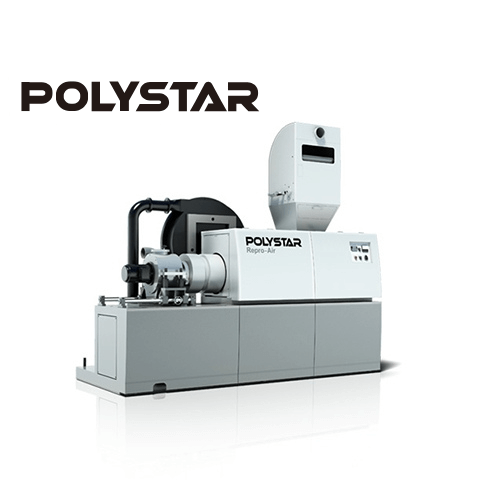

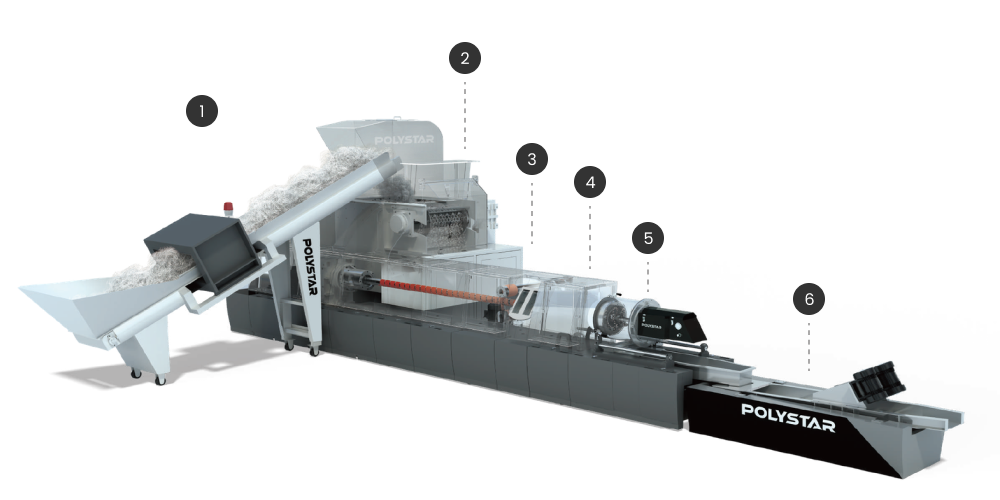

1. Feeding System

Feeding of scraps (raffia, film, lumps) is simple by a conveyor.

2. Shredding

Shredder integrated & Direct feeding to extruder: Powerful yet gentle shredder, efficient size reduction with minimal material degradation. Fast and stable feeding from the shredder into the extruder.

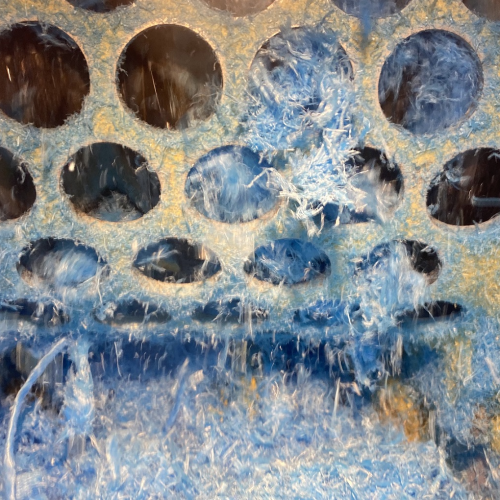

3. Filtration

Screen change with dual channel system: For non-stop operation and prevents material from leaking.

4. Degassing

Two-zone degassing (double-vented degasification): Able to process films with larger printed area and some water content.

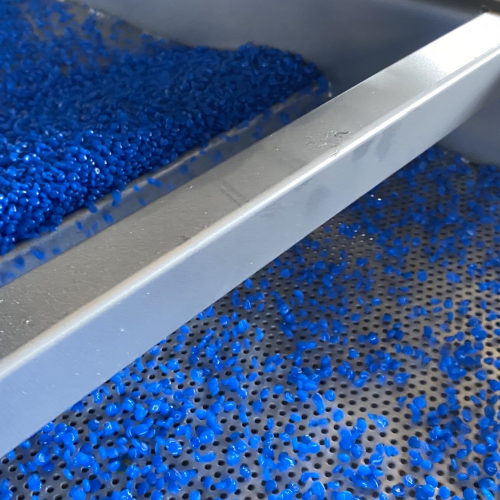

5. Pelletization

Hot die face pelletizer: Produces high-quality plastic pellets for reprocessing.

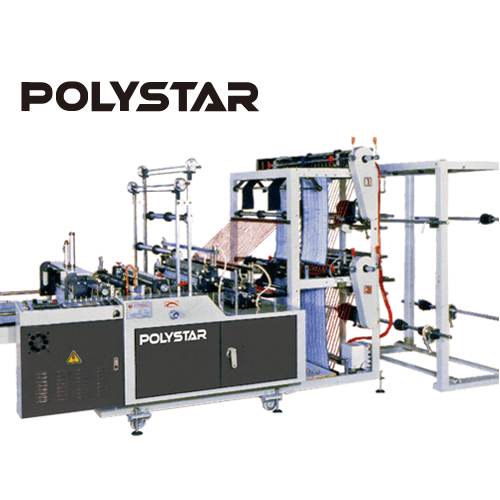

6. Recycled Pellets

The plastic pellets can be put directly back into the production line such as blown film extrusion and pipe extrusion.

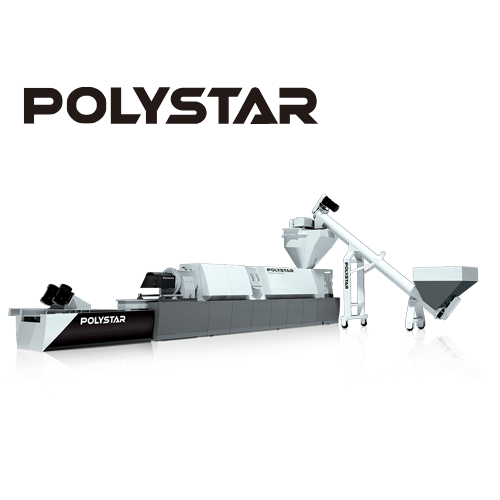

| モデル名 | リプロワン |

| 最終的な製品 | プラスチックペレット/顆粒 |

| 機械部品 | コンベヤーベルト、単軸シュレッダー、押出機、造粒装置、水冷却装置、乾燥装置、サイロタンク |

| リサイクル素材 | HDPE、LDPE、LLDPE、PP、BOPP、CPP、OPP、PA、PC、PS、PU、EPS |

| 出力レンジ | 150〜500キログラム/時間 |

| 給餌 | コンベアベルト |

| ネジ径 | 85〜120ミリメートル(カスタマイズしました) |

| スクリューL / D | 30 / 1,32 / 1,34 / 1,36 / 1(カスタマイズ) |

| ねじ材質 | SACM-465またはバイメタル |

| 脱気 | シングルまたは非印刷フィルムの未換気、通気ガス抜きダブル(カスタマイズしました) |

| カッティングタイプ | ホットダイフェースペレット化(水リングペレタイザー) |

| 冷却 | 水冷却 |

| 電圧 | 要求に基づいてカスタマイズされた(例:USA 480V 60Hzの、メキシコ440V / 220Vの60Hzの、サウジアラビア380V 60Hzの、ナイジェリア415V 50Hzの...) |

| オプション装置 | 金属検出器(S + S)、マスターバッチ用添加フィーダ、乾燥のための遠心乾燥機 |

| 納期 | 90カスタマイズされたマシンの〜150日。利用可能在庫のマシンで |

| 保証 | 1年間の |

| 技術支援 | 海外サービス機械に利用できる技術者 |

| モデル | リプロ-One85 | リプロ-One100 | リプロ-One120 |

| 出力 | 150〜250キログラム/時 | 300-400キログラム/時 | 400〜500キログラム/時 |

| 6トン/日 | 9.6トン/日 | 12トン/日 | |

| 180トン/月 | 288トン/月 | 360トン/月 | |

| ネジ径 | 85ミリメートル | 100ミリメートル | 120ミリメートル |

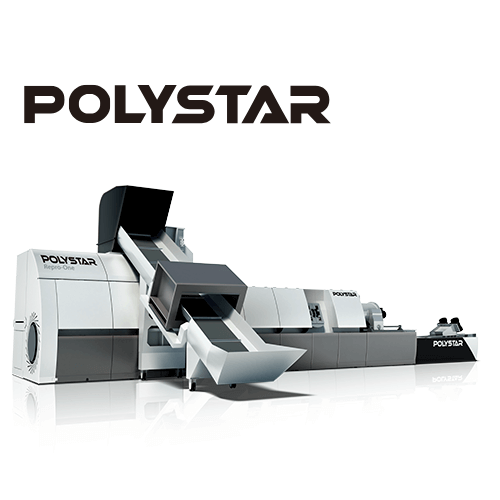

Plast India an unprecedented Success

The heavy duty single shaft shredder integrated machine generated great interest among visitors from India and other parts of the world at the fair. From day to the last day of the exhibition, Polystar carried our live demonstration of the machine processing different types of material, including PP raffia scrap, purging (lumps), PP FIBC process scrap – bags, webbing, fabric, HDPE, LLDPE film scrap, both printed and unprinted. Visiting customers were able to take a much closer look at the machine performance and the quality of the pellets produced.

The Repro One machine was sold to a PP raffia/PP non-woven manufacturer who will process their in-house process waste and reuse the high quality pellets again in their production process. This manufacturer is one of the recognized producers of PP woven and non-woven fabric and bags in India.

7 sets of Polystar’s recycling machines have been sold at the exhibition along with many more pending projects which are likely to be finalized by mid 2015. Thousands of interested visitors in India registered themselves in Polystar’s stand in 6 days.

The one step recycling machine Repro One has an integration of a heavy duty shredder which eliminates the need of pre-cutting/pre-shredding even hard plastic waste, feeding the waste directly from the shredder into the extruder at a very fast and constant rate without over heating the material. Equipped with double degassing and die face pelletizing, the line is the ideal equipment for processing all types of plastic scrap including PP raffia and woven waste, film scrap, purging, etc.

Apart from Indian clients, the machine also drew great attention from visitors from Middle East and Africa. Some new projects were finalized during the fair for various countries in Africa including Nigeria, Kenya, Morocco, Ethiopia and Tanzania.

With a remarkable success in Plast India, Polystar will again be showing its recycling machines in multiple exhibitions including NPE (Orlando) in March 2015 and K show in 2016 among other prominent exhibitions around the world.

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication

Fast online trouble shooting