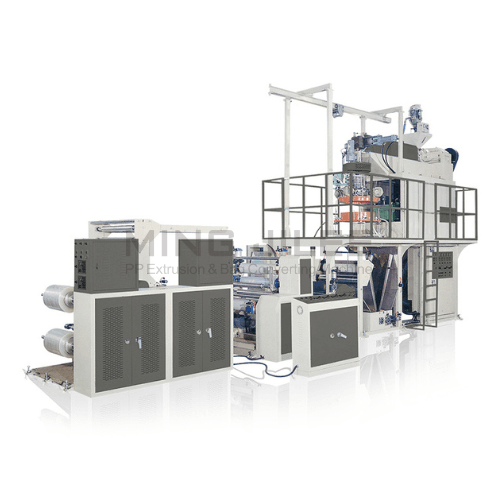

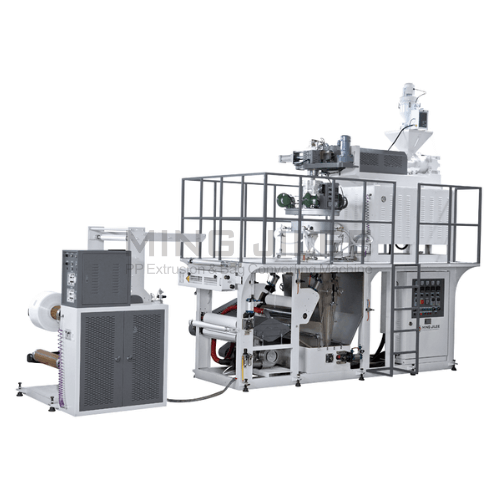

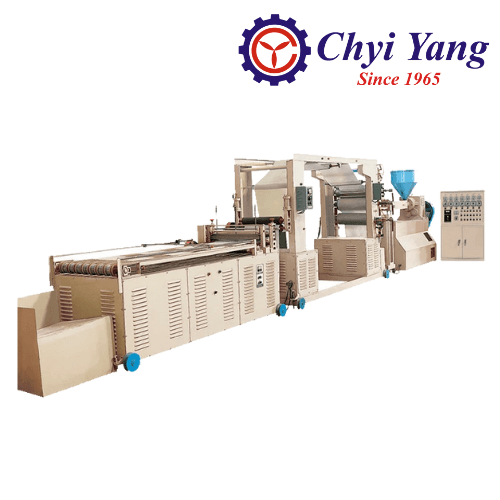

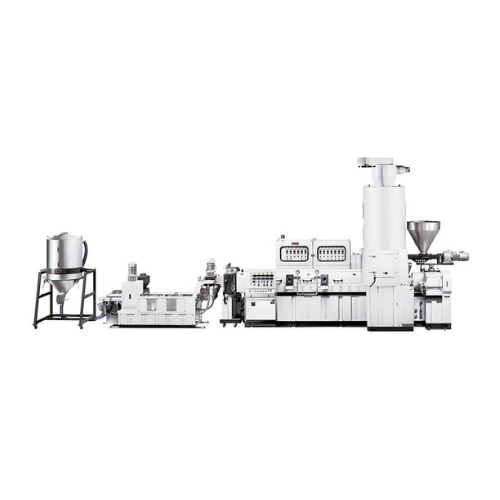

PE Foam & PE/PP Sheet Extrusion Line

カテゴリー : 発泡押出機

T-Die Extruder machine is equipped with cutter or winder to produce PP/PE sheets PP sheet is available in file cover, stationary etc. Film thickness 0.5~2.5 mm For different machines’ structure, can produce PE, PP sheet & PE foam sheet. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

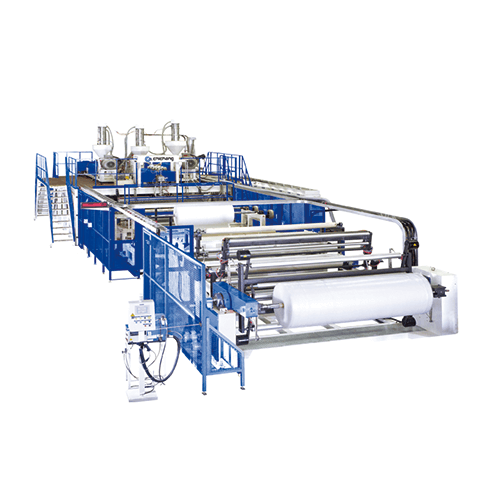

3層気泡フィルム押出ライン

カテゴリー : 気泡フィルム/シート押出機

気泡シートの主な用途は次のとおりです。帯電防止添加剤を使用した電子材料の包装。抗UV添加剤を使用した農業部門(グリーンハウス)。抗UV添加剤を使用したプールのカバー。 -研磨および帯電防止機能。封筒を作るために紙、PE織りおよびアルミホイルでラミネートされています。

(クリンパ2を有する)が2.5メートル、三層バブルフィルム押出

カテゴリー : 気泡フィルム/シート押出機

ニーズに合わせた各種モデル。シート幅は1,200MMから2,500MM、2層から10層。オーダーメイドの機械をご用意しています。

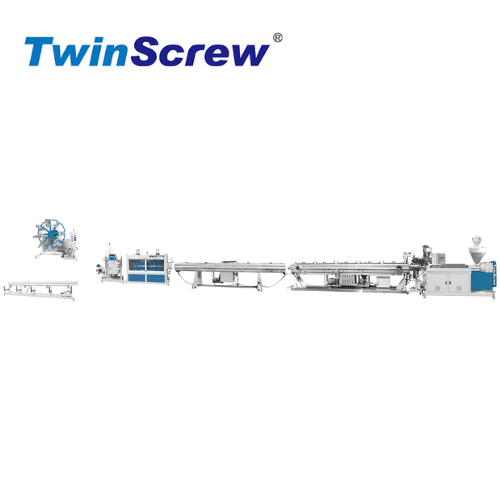

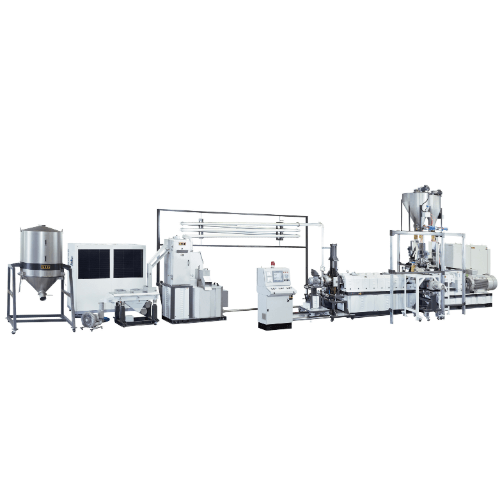

Side Force Feeder Type Recycling Pelletizing Extrusion Line | CK-SF

カテゴリー : 造粒機

CK-SF series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films.

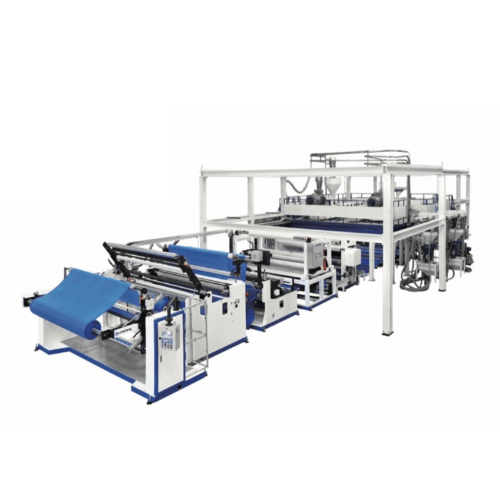

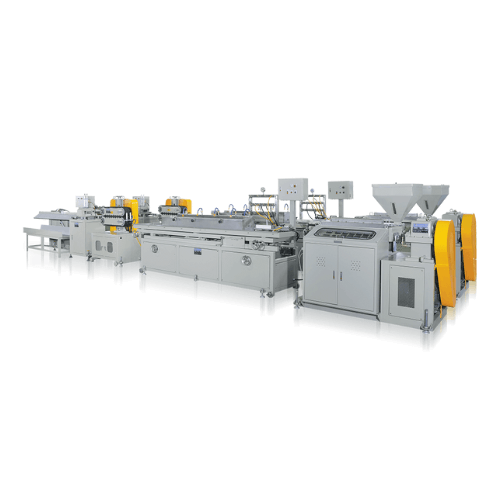

WPC PROFILE EXTRUSION LINE - PE/PP/PS/TPE/PVC

カテゴリー : パイプおよびプロファイル用押出ライン

The WPC profile extrusion line is a set of machines used in the production of WPC boards. Differences between WPC profile extrusion and general profile extrusion WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products. How does WPC profile extrusion line work? The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product. Advantages of WPC profile extrusion line Efficient and consistent production of high-quality WPC profile products. The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties. Highly automated, reducing the risk of human error and increasing efficiency. Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.

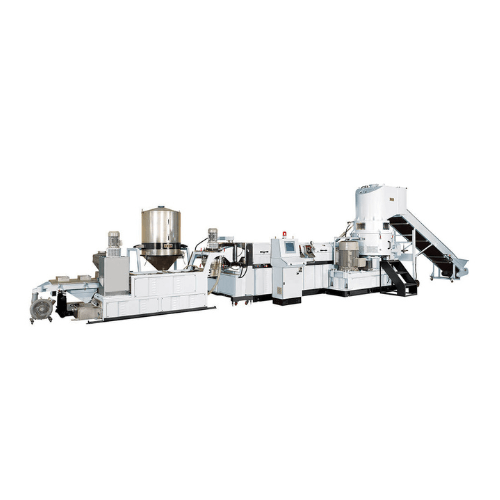

Side Shredding Type Recycling Pelletizing Extrusion Line | CK-SC

カテゴリー : 造粒機

CK-SC series Side Shredding Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic film, fiber, carpet, fabric, jumbo bag, etc. Possible materials : PP, HDPE, LDPE, PET, PC film, Nylon fiber, PP carpet, Jumbo bag, EPE, EPP, EPS, etc.

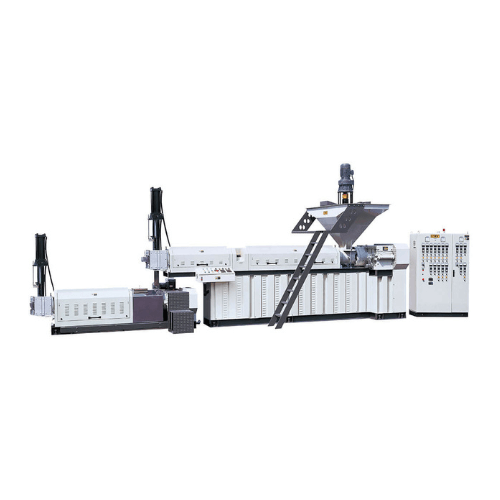

Double Section Recycling Pelletizing Extrusion Line | CK-HSD

カテゴリー : 造粒機

CK-HSD series Double Section Plastic Recycling Pelletizing Line is ideal for recycling dirty plastic flakes. Possible materials : PP, PE, ABS, PS, POM, PC, PA, PMMA, PBT, PET, etc.

Co-rotating Twin Screw Underwater Pelletizing Compounding Line | CK-HT

カテゴリー : 二軸押出機

CK-HT series Co-rotating Twin Screw Underwater Pelletizing Compounding Extrusion Line is designed especially for compounding materials with high viscosity, low MI, or difficulty to be shaped. The extrusion line can be applied to a wide range of materials and applications. Possible materials: TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.