LATEST UPDATE 購読

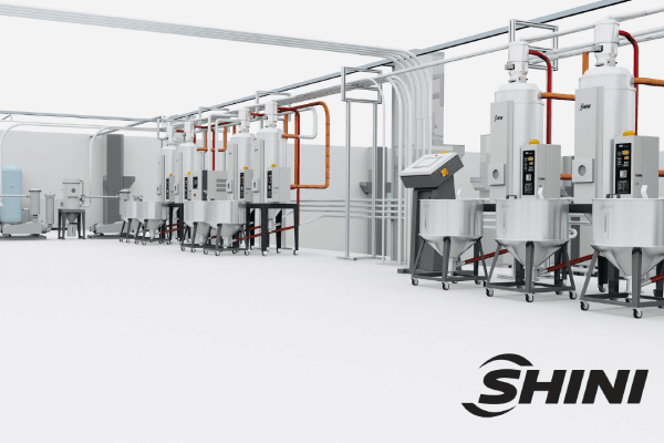

SHINI: Advantages of Central Conveying System

In the 21st century, modernization and scientific and technological development push forward the plastics industry chain's growth, and a systematic centralized conveying system has been widely deployed in injection moulding workshops of various products. It can realize the centralized processing materials and meet various unique demands such as conveying, dehumidifying...

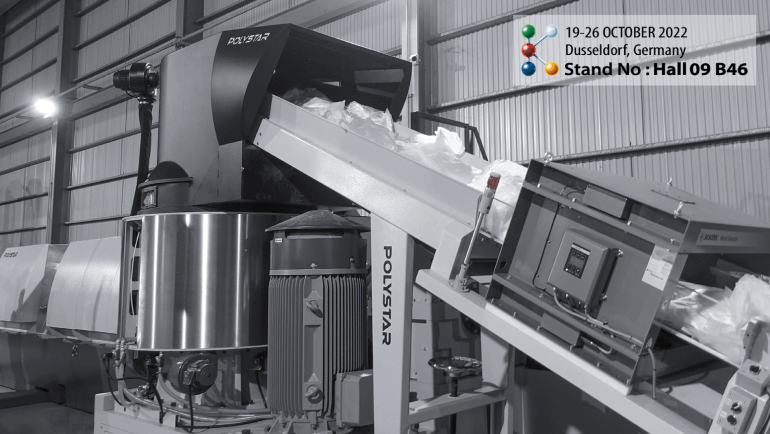

Recycling for Post-consumer and Post-industrial Plastics on the Rise

It may be good for everyone to be in the plastic recycling business whether you are a recycler or a producer. New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste. With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding.

ROTOFLEXO: High Quality Flexographic Printing Machines, Satisfying Customer Around the World

With over 30 years of experience in the gravure and flexographic printing industry, we continue to provide our clients with the best printing solutions in commercial packaging. As our business continues to grow and expand, we are in search of new technologies to help us become more environmentally friendly to build a better world for future generations. At Rotoflexo, we focus on providing the best flexographic printing solutions for small and large businesses needs...

PLASCO Demonstrates its Innovative Strength and Unveils its Latest Monofilament Extrusion Technology at K2022 Düsseldorf Germany

PLASCO is an industrial leader in design, manufactures, and distributes extrusion machinery worldwide for the production of Monofilament, Strapping Tape, Fibrillated tape, Blown Film and Melt Blown extrusion lines. At K2022, PLASCO will unveils progressive extrusion technology to international specialists under the motto “Engineered for Perfection”, demonstrate its technological innovation the field of monofilament extrusion. Visit us at K2022 in Hall 15 Stand C61...

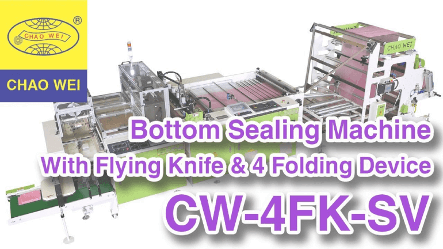

CHAO WEI: Bottom Sealing Bag Making Machine With Flying Knife System and In-Line 4 Folding Device

We hereby introduce you our Fully Automatic High Speed Bottom Sealing Bag Making Machine With Flying Knife System & In-Line 4 Folding Device By Servo Motors Control. Meanwhile, Chao Wei is happy to announce you that we are going to attend K SHOW 2022 from 19-26th October, and hope to see you at our booth Hall 12 / F14-02.

CLF: Customized Injection Molding Machine for Automotive Parts and Components

In view of the fact that CLF has clients all over the world and cooperations with Injection Molding Machinery businesses in more than 80 countries/regions, they have actively participated in exhibitions from Southeast Asia, China and Germany. Although CLF will not be able to attend exhibitions this year due to the pandemic, this challenging situation did not prevent CLF to keep on providing solutions and support to its current and potential clients.

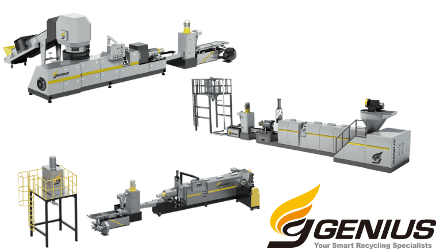

GENIUS: 5 Minutes to Understand Plastic Pelletizing Machine

Pelletizing plastics is the process that includes melting and cutting polymers into easy-to-handle plastic pellets. Understanding pelletizing system and feeding system will help you select the right plastic pelletizing machine! Pelletizers are the essential parts of plastic pelletizing machines. There are several types of pelletizing methods. Die face cutting system, also known as hot die cutting pelletizing system is the most popular used system among the other options.

HSIN LONG: Your Best Consultant of Multi-Layers Blown Film Extrusion Die Head in K 2022

Multi-Layers Blown Films market is expected to increase in the next few years. First, let’s give a brief talk about the Blown Film Extrusion Die Head. Mention about the Blown Film Extrusion Die Head, the types of die head will base on the final products. The Multi-layers Blown Film Extrusion Machine is available using different materials to produce the plastic films with various functions and well performance.

Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.

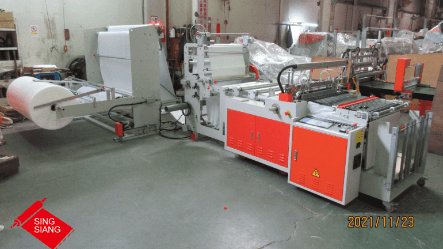

SING SIANG: EPE Bag Making Machine SHSS-30EPE

Sing Siang Machinery Co., Ltd. (SSM) is established in 1975 in Taiwan, specialized in all kinds of bag making machines and always provides customers with the most comprehensive technological service. Based on more than 40 years of design and manufacturing experience, SSM is capable of designing machines with practical performance for customers, at a reasonable and competitive price.

CHUMPOWER: Providing A Sustainable Injection Stretch Blow Molding Solution in rPET

PET is widely used packaging material for water, beverage, and food industry. It is also highly recycled. Major brands in beverage industry such as Pepsi and Coca-Cola are also planning to increase the rPET percentage within their product packaging. Many countries around the globe have launched environmental strategies such ESG...

Your Innovative Extrusioneers from PLASCO

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our speciality knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years. Our advantages • With 2 manufacturing factories in Taiwan including test center. • More than 3600 PLASCO extrusion lines all over the world • Installed the extrusion lines in more than 80 countries worldwide • Focus on innovation and quality: independent R&D dep. and electrical engineer • Customized and top quality to satisfy customers • Convenient to find spare parts all over the world: we use the well-known global components for machines Work with PLASCO • Customized design & auxiliary equipment provided • Efficiency & exact lead-time • Service & support: installation, operation training, and technical knowledge support • CE certificate of compliance With its high level of reliability, efficiency, energy saving concept, and top quality finish product, PLASCO plastic extrusion line ensures the modest investment compared with its high productivities to facilitate the ever-demand requirement of all market sectors.