LATEST UPDATE 購読

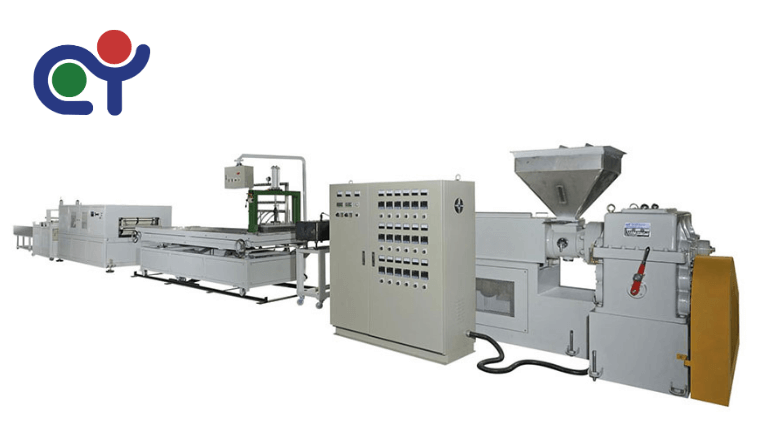

WPC PROFILE EXTRUSION MACHINES - 6 KEY FACTORS

Investing in WPC profile extrusion machines is a crucial decision that can significantly impact your production capabilities. However, with so many options available in the market, selecting the right machine that fits your business needs can be a daunting task. To help you make an informed decision, we have put together a comprehensive guide outlining 6 key factors that you need to consider when selecting WPC profile extrusion machines. In this guide, we will cover everything from material compatibility to output requirements, giving you a clear understanding of what to look for in a machine. By the end of this guide, you will have all the necessary information to choose a machine that maximizes your production efficiency, quality, and profitability. So, keep reading to learn more and make an informed decision that will benefit your business.

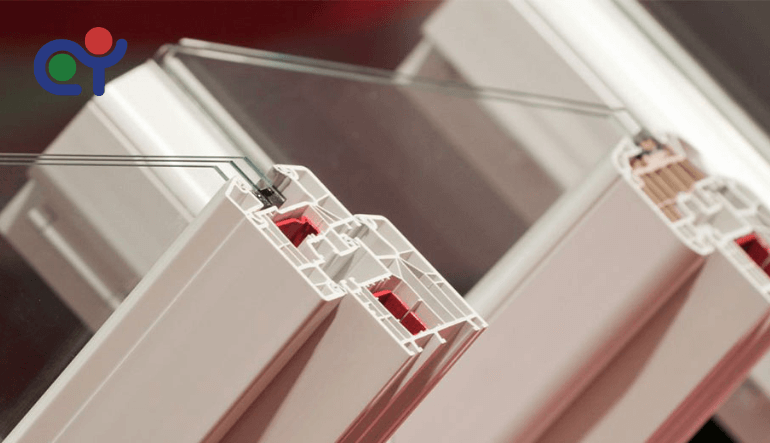

UNDERSTANDING WPC PROFILE MACHINES IN 5 MINUTES

WPC profiles have become increasingly popular due to their natural look and feel of wood combined with the durability and low-maintenance benefits of plastic. WPC profiles are widely used in the construction industry for outdoor decking, fencing, window, door frames and railing, as well as in automotive and furniture industries. WPC profile extrusion machines play a critical role in producing high-quality WPC profiles efficiently. In this article, we will explain the basics of WPC profile extrusion machines and how they work.

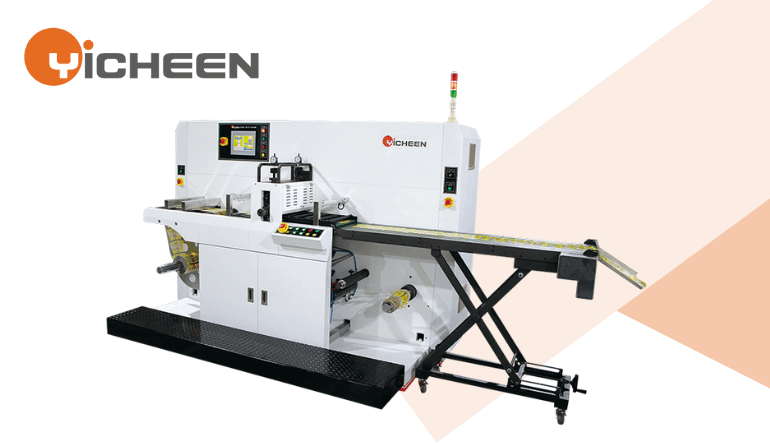

YICHEEN: The Importance of Label Die Cutting Machines

If you want to make the most out of your label converting machines, it is important that you understand how it works. There are two main types of label die-cutting machines for label converting : rotary and flatbed. The best way to learn more about label converting is by talking with experts who have experience designing specific applications. YICHEEN is one of the leading label die cutting machine manufacturers.

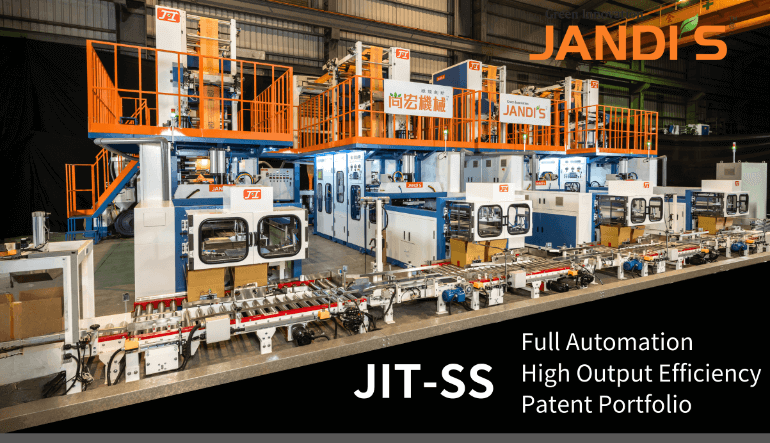

JANDI'S: JIT now available with full auto carton package line

JANDI'S JIT introduces a fully automated T-shirt bag production line with carton packaging. This system integrates blown film, printing, bag-making, and recycling, ensuring swift and precise operation. Capable of producing over 25,000 T-shirt ji3bags per hour, it auto-packages in carton boxes, requiring only three operators. JANDI'S JIT combines efficiency, high output, and cost-effectiveness, making it ideal for optimal T-shirt bag production.

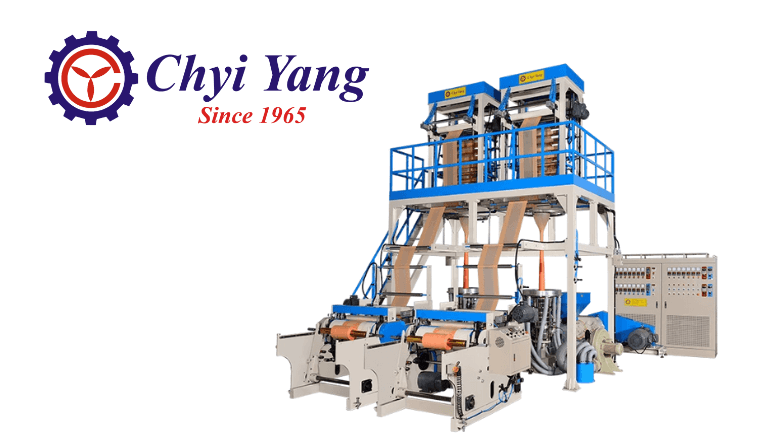

CHYI YANG: The Features of HDPE Bags & Film

High Density Polyethylene Resin, briefly, HDPE film grade resin mainly designed for producing shopping bags, T-shirt bags, grocery bags, garbage bags, food packaging and many so on.

CACO3 & Recycling Material Revolution in HDPE Bags

Nowadays, for HDPE shopping bags, T-shirt bags & food packaging bags, it’s very popular to blend recycled material & calcium carbonate (CACO3). Especially CACO3, it can cut down your resin cost, increase capacity & make your film products heavier. Although CACO3 provides so many advantages, it changes the feature of HDPE film. HDPE film will be reduced in tensile strength after blending CACO3, so that HDPE film won’t pack heavy subjects. Besides, CACO3 will make HDPE film feels dusty.

40th Techmation: Digital Low Carbon Dual Wheel Drive, Intelligent Manufacturing in the Future

2024 marks the 40th anniversary of Techmation. Over the past 40 years, Techmation has taken the first Chinese screen injection molding machine controller in Asia as the starting point, vertically breaking through technological barriers, horizontally expanding product applications, and steadily drawing an industrial application map with Techmation control system as the core.

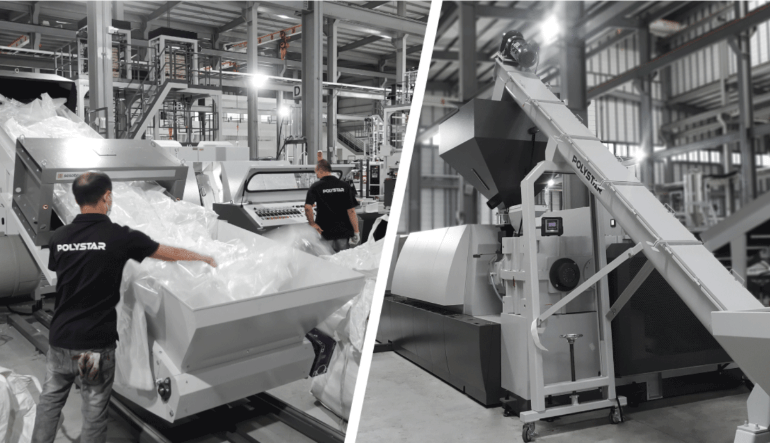

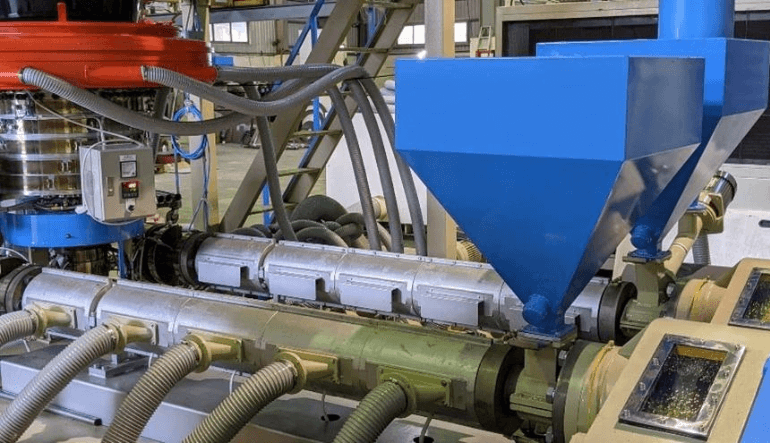

POLYSTAR Pelletizers for Soft and Rigid Plastic Wastes - Which Granulating System Can Fit Your Demands Best?

Different plastic materials have their unique properties and are manufactured into many categories of products such as plastic films, food packaging, flexible plastic packaging, medical device components, etc. While recycling the plastic waste from particular materials, the plastic pelletizers chosen must be capable of processing your main waste stream, as well as flexible enough to process your side plastic waste.

Guide to Blown Film Extrusion Machines

The process to produce the film is similar to blowing bubbles. The blown film machine virtually replicates the blowing process on its tower-like production line except it uses polymers (plastic materials) to replace soap water and nip the continuously blown bubble into an extremely thin film. The tower structure ranges several stages high. After the film is formed, it is wound into rolls and later distributed for final applications. As one of the leading blown film extrusion machine manufacturers with over 50-year-experience in Taiwan, now CHYI YANG is going to break down the process into details and discuss how blown film extrusion works.

GMA Machinery's Evolution from Extrusion die Craftsmanship to Slot Die and Coating Equipment - A Journey of Unwavering Excellence

For over 30 years, GMA Machinery, with its rich experience in extrusion die design and manufacturing, has caught the attention of global extrusion machine market. What prompted GMA Machinery to smooth transition from specialized extrusion die design and manufacturing to enter the slot die and coating equipment and equipment sector? How did it swiftly emerge as the new choice for slot die and coating equipment in the optoelectronics and precision manufacturing industries?

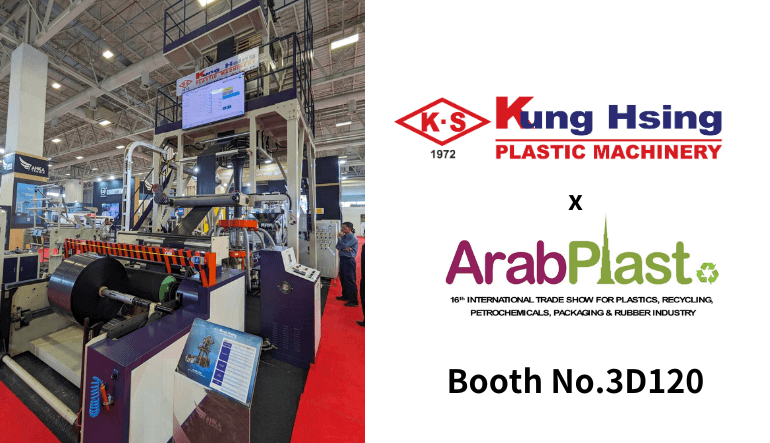

Kung Hsing's Sustainable Solutions: Revolutionizing the Plastic Industry for a Greener Future

Sustainability is about our next generations, and it is what we give them when we leave the world. The resources on our planet are limited, and it would be exhausted one day. Plastic Industry is commonly associated with a destructive factor to the environment. However, people should be aware that not all plastic is disposable, and most of them could be reuse and recyclable. More and more countries had different policy on the plastic, in order to reduce the plastic consumption volume.

Recycling Materials with POLYSTAR for New End Product Possibilities

With consumers increasingly pushing for less raw material usage, the last few years have exhibited an increase in recycled plastics as basic materials for production, helping repurpose products that otherwise would be considered waste. But what type of plastic materials can be recycled? How can plastics be recycled? And what end products can be made using recycled materials?