LATEST UPDATE 購読

Scientific Molding Thinking: Molding is a Science not an Art

Injection molding is the process of converting plastic materials into flowable molten plastic materials by an injection molding machine, and injecting them into a mold cavity where they are cooled and solidified to form the final product. Plastic materials are less expensive to obtain compared with other materials such as metal, wood, and ceramics. In addition, it is easy to produce complex geometric products in large quantities with plastic materials, so people constantly extend the application of plastic products to various types of products. However, the complex flow behavior of plastics due to their viscoelastic property has led to many specious and erroneous experiences in injection molding, which may easily mislead the direction of problem solving.

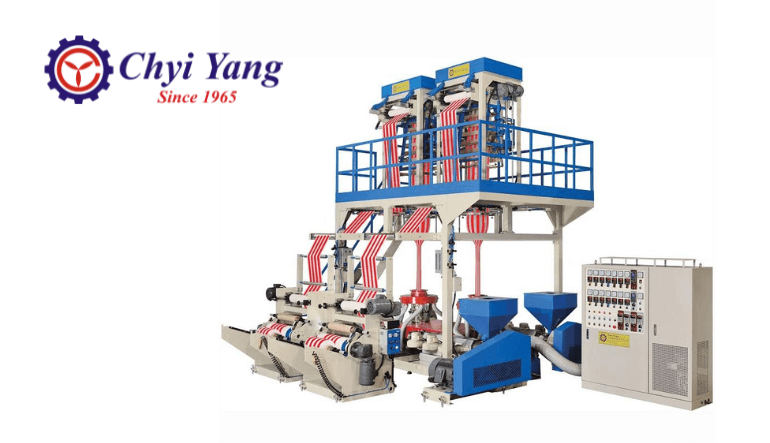

The Fastest Rewinding Machine Made In Taiwan

Chyi Yang developed a new PE Stretch Film Rewinder Machine. The Rewinder machine mainly is used in rewinding stretch film & cling film. This machine is fully automatic, it can feed the paper core, rewind film, cut film and change paper core, glue & label automatically. Chyi Yang is expert in developing PE stretch film whole equipment for more than 50 years.

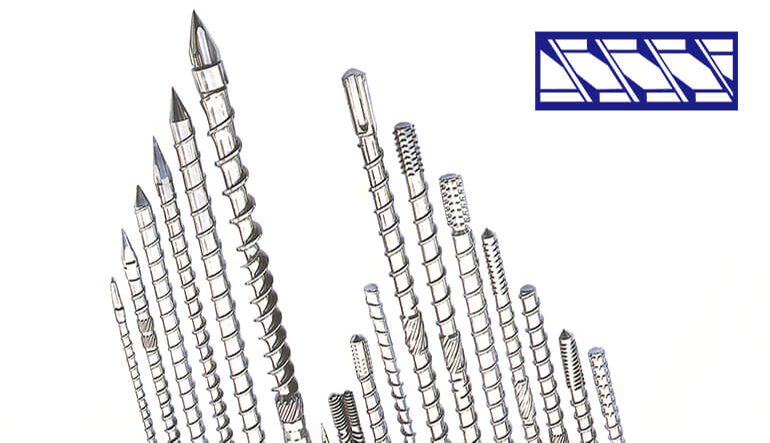

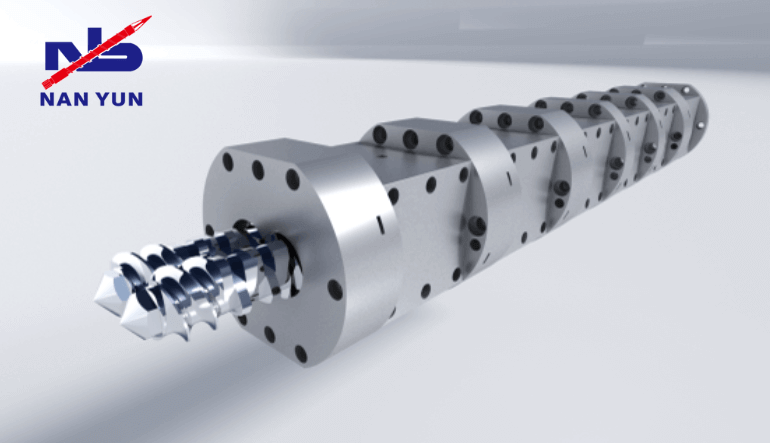

Customized Perfection: How LUNG CHANG Meets Clients’ Needs with Precision Screws and Barrels

During the pandemic, one of the biggest challenges for the plastic machinery industry is the travel and logistics limitations. No matter after sales services of the manufacturers are good, once it comes to the maintenance and parts requirements, current transportation and logistics obstacles might cause the manufacturers delay in their business. Therefore, many plastic machine manufacturers prefer to use the parts, such as screws and barrels, that are high quality and meet customers' requirements precisely in their machines. In this case LUNG CHANG is one step ahead in the industry with its reliable extruder screws and barrels as well as injection molding machine screws and barrels.

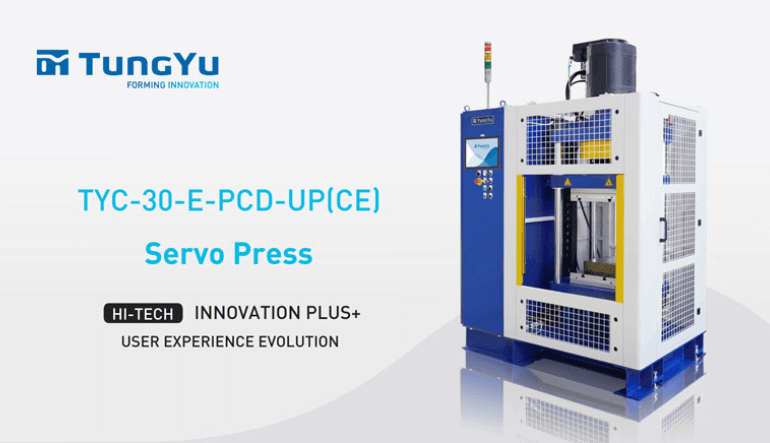

TungYu Servo Press: Revolutionizing Manufacturing with Sustainable Power

Are you looking to enhance your manufacturing processes while minimizing environmental impact? TungYu's advanced all-electric servo press offers a sustainable and efficient solution. By replacing traditional hydraulic systems with high-performance servo motors, our servo press achieves significant energy savings and a reduced carbon footprint.

THE LATEST GENERATION OF PET BOTTLE WASHING LINE—ES PROCESS

In response to the PET industry’s quest to increase recycled content by producing high-quality rPET flakes for high-end applications, BoReTech has leveraged its 30 years of experience in recycled polyester industry and developed a total solution for plastic recycling, endeavoring to be a global pioneer in plastic recycling ingenuity.

PE Cling Film Produced By CHYI YANG’s Machine Owns 80% of China Market Share

Nowadays, Stretch/Cling film are very common used in daily life, for industrial packing for foods or general goods, and even at home to protect and storage prepared food. There are several materials formulated for its production, being Polyethylene the most convenience for easy processing, because it is suitable for food contact and for easy recycling.

JingDay: A Pioneer in Rubber and Silicone Molding Technology, Forty Years of Expertise Yielding Diverse Applications

Rubber and silicone are no longer unfamiliar materials to most people. With their excellent elasticity, insulation, heat resistance, cold resistance, and outstanding electrical properties, it's easy to spot applications of silicone rubber in daily life. Since its establishment in 1983, JingDay Machinery, with its 40 years of knowledge and technology in rubber and silicone molding, has not only developed various specialized machinery for customers but also covered application fields such as automotive, motorcycles, 3C products, medical, sports products, and golf products.

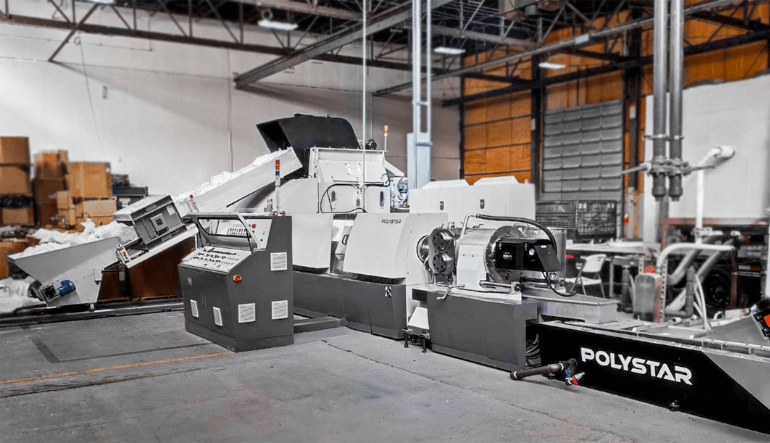

BDB Recycling Leads the Way with POLYSTAR's Innovative Solutions

POLYSTAR is dedicated to creating innovative pelletizing machines that empower businesses to contribute to a more sustainable future. We'd like to highlight one of our valued customers, BDB Recycling, located in Ohio. BDB Recycling shows how our pelletizing machines can revolutionize LDPE/HDPE recycling operations, not only boosting their business but also paving the way for a more circular plastics economy across the US.

Studying Hard at Night School Turns Poor Students into Corporate Directors

Guo Mingyi, chairman of CHYIYANG Industry, has five companies in Taiwan and the mainland. The plastic wrap machinery products are sold in 60 countries in Southeast Asia, mainland China, Central and South America, and Europe.

CHYI YANG Has Sold Over 500 Sets of Blown Film Machines to Latin-America

Chyi Yang showed one set “Two Stripes & Two dies Co-Extrusion Blown Film Machine” in Colombiaplast 2016 exhibition. This machine is equipped with two dies & two extruders to produce two stripes T-shirt bags for market using. This series is very popular because of mainly for following reasons.

Sustainable Innovation in Extrusion Technology: NAN YUN’s Co-rotating Twin-Screws

Established in 1993, NAN YUN Industrial Co., Ltd. is a leading supplier of essential components for injection molding machines, extruders, and related machinery in the plastic and rubber industry. Our dedicated engineering design team combines exceptional theoretical knowledge with practical expertise, specializing in the meticulous design and production of a wide range of screws and barrels.

Transition to a Bio-Based Economy: Worley Takes on FEED for Avantium’s New Plant

Worley has been awarded the front-end engineering design (FEED) contract to develop Avantium’s flagship plant, supporting the transition to a bio-based economy for plastics. This plant will produce 100% plant-based FDCA (furandicarboxylic acid), a crucial component for various chemicals and plastics.