Tung Yu: Your One-Stop Service for Hydraulic Presses and Conveyor Belt Production Lines, Ranging from 5 Tons to 13,000 Tons.

Since 1983, Tung Yu has been a seasoned expert in hydraulic machinery, holding ISO 9001 approval and CE certification. We offer a diverse range of products, spanning from 5-tons hydraulic presses to 13,000-tons conveyor belt production lines. Our services extend to comprehensive One-Stop Shopping for our customers. Our product lineup encompasses Compression Molding Machines, Rubber and Liquid Silicon Injection Molding Machines, Conveyor Belt Vulcanizing Machines, Tire Molding Machines, and Retreading and Solid Tire Molding Machines.

Tung Yu specializes in manufacturing steel cord conveyor belt vulcanizing machines, offering capacities of up to 13,000 tons based on market demands. Our multi-station setup ensures convenient and safe production processes. Addressing diverse customer needs, we provide tailor-made services. Our curing presses can be designed with main cylinders on the top or bottom to accommodate factory layouts. Automation guiding mechanisms on both sides ensure the precise alignment of material belts. With extensive expertise in mechanical design, program development, machine installation, turn-key facility setup, safety protocols, and productivity optimization, Tung Yu serves as a comprehensive solution provider. Our primary goal is to consistently deliver the utmost value to our customers.

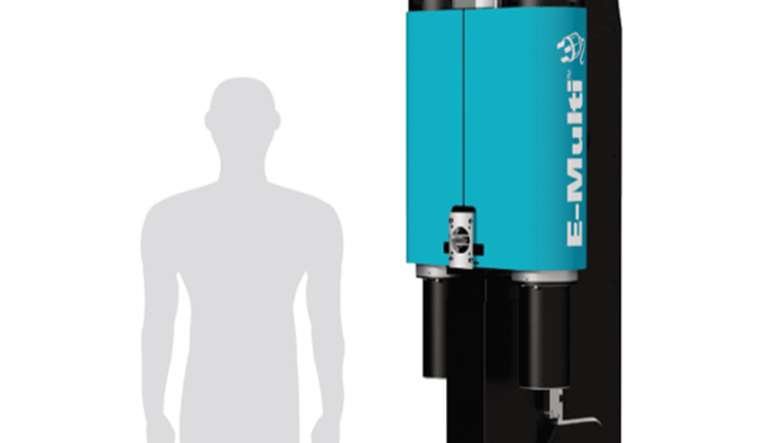

Steel Cord Conveyor Belt Vulcanizing Machine (Down Stroke)

Mechanical feature at a glance

- Central control system by PLC and touch screen.

- Equipped with cooling system on the bottom of cylinders to prevent oil temperature increase and maintain performance.

- The bottom of cylinders is contacted to platen with full pressing area to have even pressure and better product quality.

- The seal of cylinders is located far from platen to have longer life cycle.

- Top cap of cylinders is designed with oil return hole to prevent product polluted from leaking.

- Heating platen size customized design is available.

ROTOCURE machine can supply continued curing and compressing for special required product. Mechanism strength is based on CAE and FEA analysis to ensure enough safety factor. Utilizing Sweden-made SANDVIK steel belt for stable and even working pressure (option: Berndorf or other brands). Otherwise, steel belt position is adjusted by automatic photoelectric tracking device. Once belt position offset, alarm message will be active for safety purpose. Individually radiation auxiliary heating system is optional temperature control for curing process. Operation is quite accuracy and facility. Depends on each customized need, ROTOCURE also provides different let-off and wind-up station and other auxiliary equipment to guarantee product quality. For automatically process and higher production capacity, TungYu ROTOCURE will be most functional equipment.

Mechanical feature at a glance

- Continuous vulcanizing process provides high production efficiency and stable quality.

- Auto latching chuck for safety and promptly loading/unloading material shaft.

- Control system by PLC and HMI to easily and precisly set up temperature, pressure,speed and other production parameters .

- Auxiliary equipment such as let-off and wind-up device, steel belt quick exchanging mechanism and tension side spacer is available.

- Customized design for CE and OSHA conformity machine.

Composites Compression Forming Machine (Down Stroke)

Mechanical features at a glance

- Shuttle mold by sliding cart with smooth and precise movement.

- Down stroke design with lower working height.

- Special tilt angle for different mold design.

- With separate operational boxes to secure safety.

- Multiple forming modes as to special process requirements.

- PLC control is compatible with materials pumping process.

Fiberglass Products Forming Machine

Mechanical features at a glance

- Down stroke design with lower working height.

- Double stations with the sliding carts increase the productivity.

- Sliding carts with position pins to secure working safety.

- All heating wiring, vacuum line, air hose, and electrical cable are protected by track during mold sliding process.

- Mechanical structure depends on products size and production.