Plastic Bags on Roll Making Machine Series | CHAO WEI

Introducing a full range of Plastic Bags On Roll Making Machine Series from CHAO WEI, which is a pioneer plastic bag making machine manufacturer in Taiwan with more than 35 years of experience in this field. 【SPECIALTIES OF CHAO WEI】 Bag on Roll Machines T-Shirt Bag Making Machine Side Sealing Machines Bottom Sealing Machines Whole Plant Equipment 【ABOUT CHAO WEI】 CHAO WEI Plastic Machinery Co., Ltd. is an advanced manufacturer of plastic bag making machines with more than 35 years of experience with ISO 9001 & CE certificate in Taiwan. CHAO WEI’s main goal is to enhance the value of machines and to create new performance capabilities that will meet the customers’ production efficiency and profitability.

Plastic Wood Composite Profile Extruding Machine | CHEN YU

Plastic Wood Composite Profile Extruding Machine | CHEN YU CHEN YU PLASTIC MACHINE CO., LTD is a professional designer and manufacturer in Plastic Wood Composite Profile Extruding Machine.

Turkish Plastic Market Evaluation | PDA GLOBAL Interview (POLYSTAR Agent)

PRM Media Channel continues to share with you the most current industry insight into local markets around the world. This time our guest of PRM Industry Insight program is Mr. Emrah Cakir from PDA GLOBAL company, as well as the agent of POLYSTAR in Turkey. We have touched on many current topics of the plastics machinery industry including the shipping obstacles, current plastic packaging machinery demand of the Turkish market due to emerging needs, advantages of having a local agent in the Turkish market, the fluctuation in the foreign currency in the Turkish market, and so on. Let's take a look at the video and hear more from Mr. Cakir about his solution suggestions to the current issues in the market. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

Plastic Recycling Machine -Genius- Plastic film squeezing machine Specializes in plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. The latest solutions for film washing line If you would like to produce the high quality and validity of pellets, you beware "Squeezing process must be prior to pelletizing process". After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers’ needs. Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders. Speed-changing gearbox We adopt a self-made gear box with high technology precision. Our single screw squeezer is equipped with a gearbox with two-speed derailleurs. According to characteristics of the materials you feed, you can choose which speed you want. You don’t need to buy another squeezer when you feed another kind of materials. It makes the whole washing line more efficient and saves much space. High Productivity Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps . The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~960kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don’t need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity. Always your best choice Our single screw squeezer can help you SAVE cost, SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. It is definite your best choice! You NEVER miss it.

2024 InterPlas Thailand Interview | SHINI

In this video, we have the pleasure of interviewing Siwakorn Tachapanich (Bank), the Sales Executive of Shini's local agent in Thailand. Shini boasts an exceptional sales and engineering team in Thailand, always ready to provide top-notch service whenever needed. Watch as we delve into their operations, commitment to customer satisfaction, and the unique advantages they bring to the market.

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

Twin Screw PVC Pelletizing Line | TWIN SCREW

We are a pioneer of twin screw extruder. Description: TWIN SCREW EXTRUDER ⚫With two parallel counter-rotating screws for the palletizing. ⚫Reduction and torque-distribution unit with hardened, ground shafts and gear. ⚫Long service life for the processing units due to lower specific drive energy. ⚫Increased process reliability due to modern control technology. ⚫Easy maintenance and service. DIE FACE CUTTING ⚫Hinge flange type. ⚫High speed rotation of the knives. ⚫Continuous production of granulate. VIBRATION COOLER ⚫Up & Down two vibrating bed. SILO TANK ⚫Stainless steel. Our Service: Technology innovation, perfect service, and internationalization are always our core values, with this mission we have become the pioneer of twin screw extrusion in the global market and a reliable partner of our customers. TwinScrew will never stop progressing in the field of PVC extrusion and twin screw extrusion; we will no doubt lead the twin screw technology into an ultimate and great attainment.

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

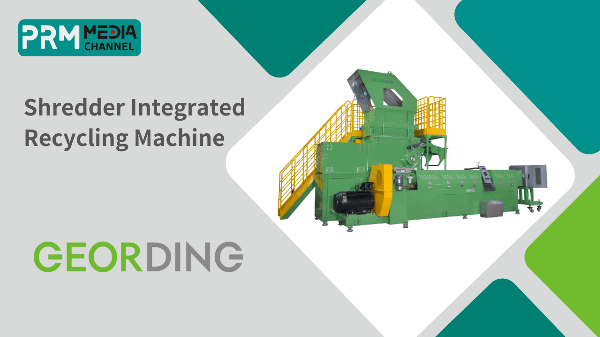

Shredder Integrated Recycling Machine | GEOR-DING-

Shredder Integrated recycling machine Features: -Can handle large heavy materials or thin-film materials 0:50 -Automatic backfllush screen changer,Reduce the screen changing labor cost 1:03 -Side Feeding Twin Screw design

Contribution to Circular Economy & ESG Implementation | GEORDING

In recent years, many manufacturers in the plastics industry have been aware of the environmental issues to reduce waste and protect our environment. GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well. Through the interview with the sales manager, Jessica Liu, she expressed the implementation of Reuse, Reduce and Recycle are core concepts to GEORDING. With the Refuse Derived Fuel production line, they could share the idea and provide assistance to lower greenhouse gas emissions. Supporting their customers is the priority of after-sale service. Even though the pandemic has been affecting the world, GEORDING still maintains an excellent relationship with customers by arranging video meetings and providing the service of remote tests. Therefore, they have been awarding the OEM cooperation with a long-term partner in Japan. One of GEORDING’s customers in Japan uses their RDF (Refuse Derived Fuel) to plant vegetables by using their equipment. As a result, we could tell that more and more manufacturers value the sustainability of ESG. 【Video Outline】 00:00 - Introduction 00:39 - Contribution to the circular economy 02:03 - RDF production line for ESG 03:06 - After-sales service for installation & maintenance 04:01 - OEM cooperation 04:39 - R&D developments 06:20 - Customer success stories 07:40 - Closing

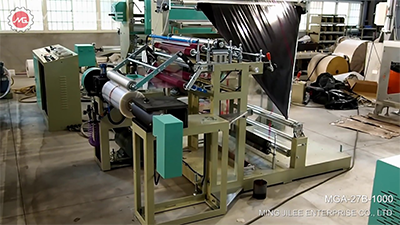

Triangle Folding Machine & 1 Color Rotogravure Printing Machine | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES OF THE MACHINE: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.