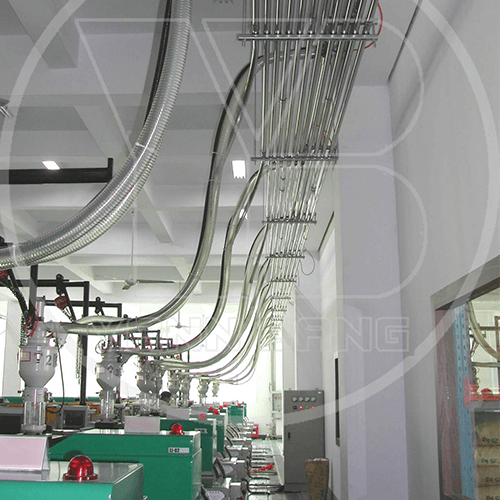

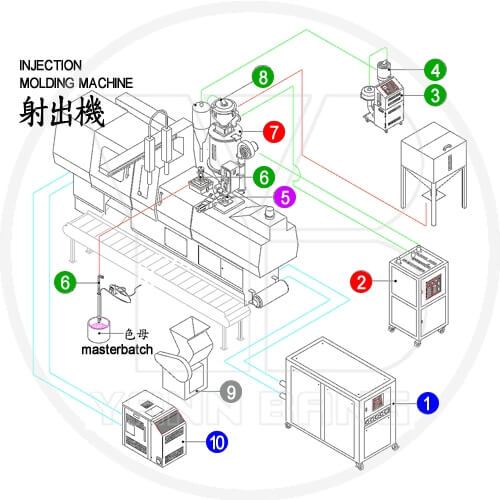

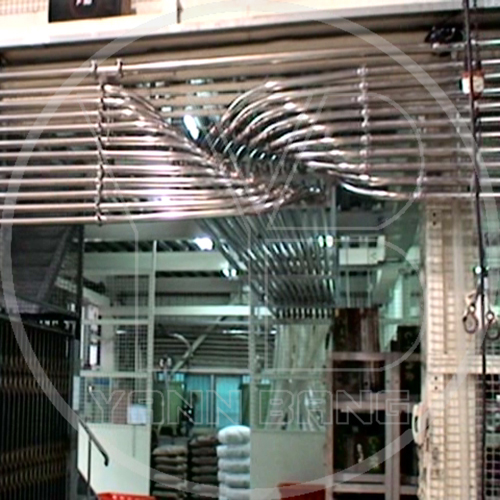

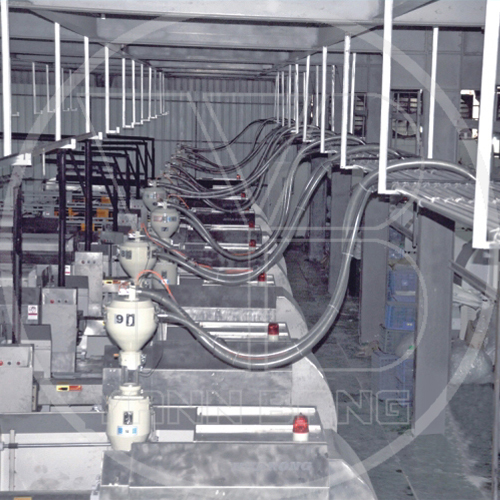

集中型空気圧供給システムとも呼ばれる当社の中央真空搬送システム。 プラスチック加工に合わせて完全にカスタマイズして、ダウンタイムのない連続運転の目標を完全に満たすことができます。

1つの中央搬送システムで30セットの成形機を同時に制御し、2〜3年で投資を回収できます。

-

より良い会社イメージ

-

生産性の向上

-

より低いコストで

-

より良いエネルギー効率

-

運搬プロセス中の材料の無駄と汚染が少ない

-

より良い職場環境

-

ブロワーを作業場所から分離することによるノイズの低減

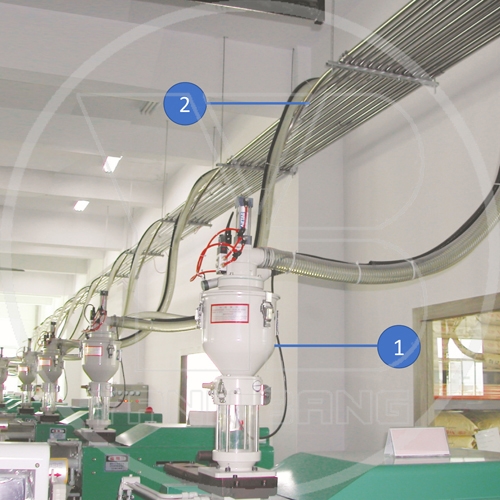

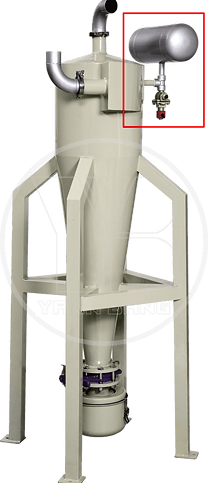

Suction Hopper

-

Standard Series (HS)

By negative pressure principle, convey the raw material into the hopper controlled by the limited switch.

-

Glass series (GS)

Fitted with a proximity switch to make the accurate control and the material supply easily observed. It can be mounted directly onto the molding machine and gives the operator a clear view of the loading through the sight glass.

-

Stainless Series for Optics (HS-S/GS-S)

The stainless suction hopper which is internal buffed is dust-free and best choice for optics industry.

-

Booster Series (HS-E)

Flexible Hopper design to increase or decrease your hourly capacity is economic and user-friendly.

-

Dust-Free Filter Hopper for optics (HDF)

During conveying, dust and resin are separated. To compare with other air filter, it can increase 300% efficiency to de-dust. Stainless design with transparent tempered glass gives a clear view of the loading, and it is perfect for optics need of dust-free.

-

Powder Series (HSP)

Working with a floor-type auto loader (TAE series) .It is the best choice for powder user. Available for powder, pellet or flake resin. Both new and recycled material are no problem. Special design to prevent dust and keep workshop clean. No longer worry about the powder jam at the bottom.

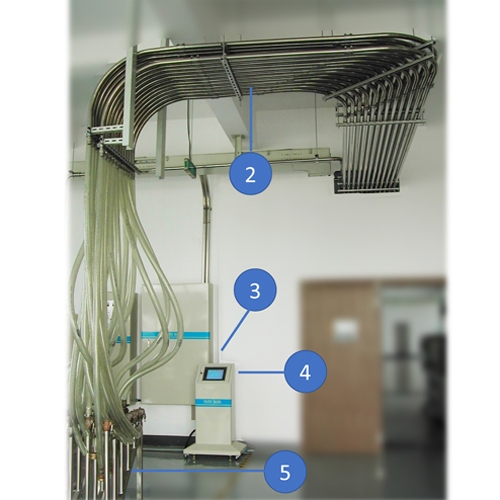

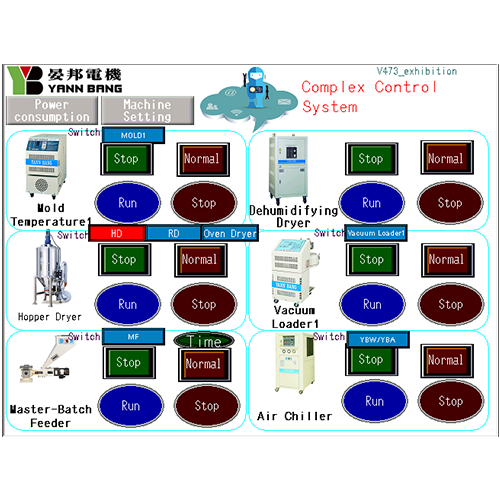

CMS Central Controller

1. One-of-kind design of integrating the monitoring panel and the control panel.

2. User-friendly interface and accurate control.

3. Operating and monitoring by a single personnel and can be linked with computer remote maintenance program to reach the most efficiency controlling mode.

4. Conveying time, material types, and pipe cleaning time of each station are adjusted by the control station.

5. Displaying panel shows you how each station, dryer, and storage silo work, such as on / off, full or lack of material, and material type of each station.

6. Extensive interface allows easy expansions up to 40 stations for future demands.

7. Compact and durable design.

Microprocessor Touchpad Controller

‧ Operating status : Display the operating status of units

‧ Set-up status : Display the set up status, such as working stations, material types, material conveying time, and pipe cleaning time.

‧ Abnormal : Display abnormal units and material types.

オプション:自動洗浄装置

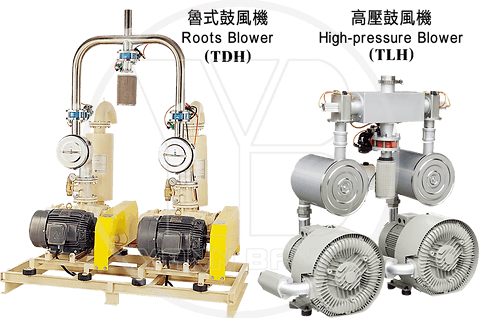

高圧ブロワー:短距離

ルーツブロワー:長距離