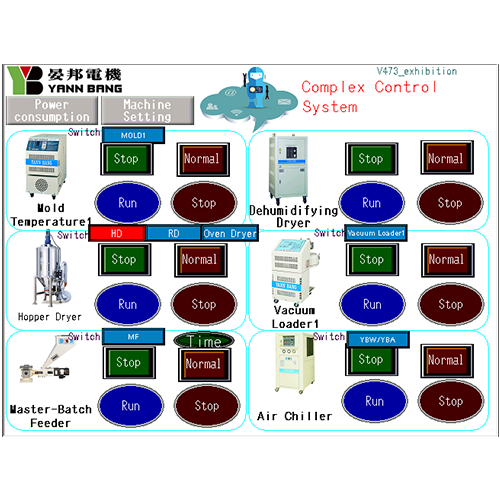

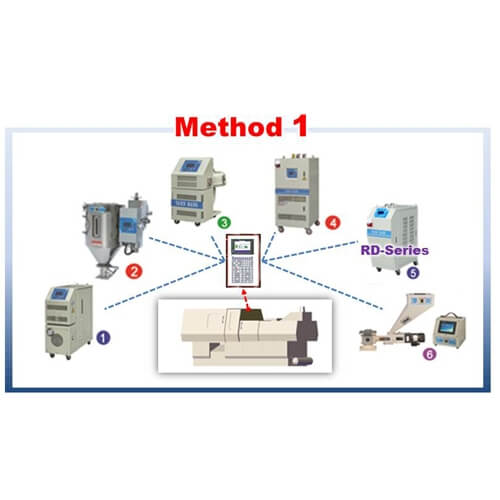

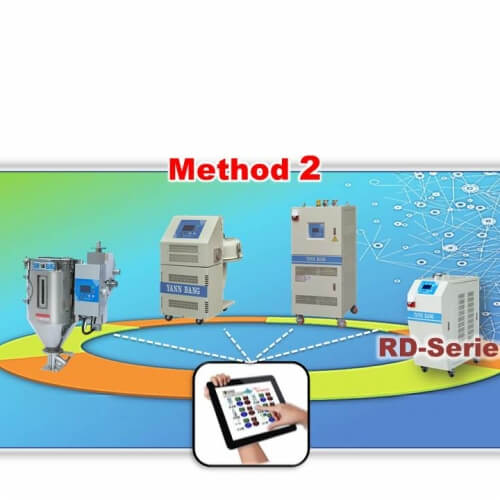

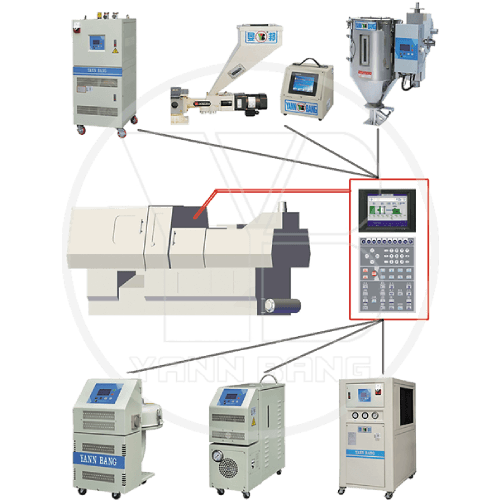

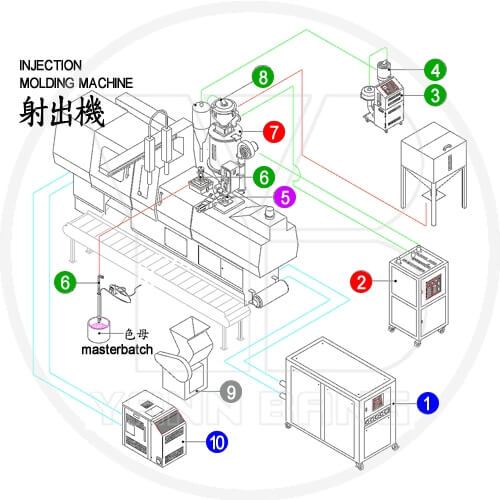

WT(Wise-Transit) Net 4.0

The automatic plastics processing can be controlled by the method of Industry 4.0, Modbus Protocol and RS-485, supplied by Yann Bang, professional experienced programming design and related compatible equipment, to offer you a best solution to a smart factory.

-

Provide the complete production resume for tracking and analyzing.

-

Record the best parameter setting and the experience can be inherited.

-

Machine maintenance can be reffered to and reminded.

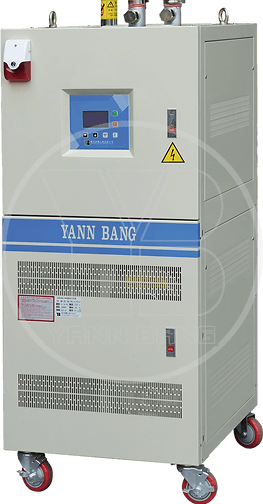

Mold Temperature Controller (YBMI/YBMD)

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc....

P.I.D temperature controllers are used for accurate control of temperature within±1℃.

Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently.

-

YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above.

-

YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

独自の断熱ホッパーは、高温で繰り返し加熱に耐えることができます。 高いセキュリティと十分な除湿。 軽量で成形機に直接取り付けが簡単です。 ステンレスとポリッシュの1つのユニット設計は、ほこりや汚れがありません。

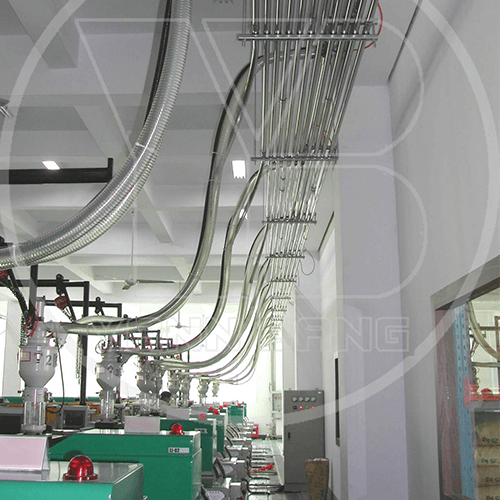

強力な馬力を備えたブロワーとサクションホッパーの分離設計は、長距離輸送に適しています。 それはあなたの樹脂を汚染から遠ざけ、将来の必要性のために吸引ポイントを簡単に拡張します。

1.セラミックファイバーのハニカムをインポートし、乾燥空気の-40°C未満で露点を超えます

2.インテリジェントマイクロプロセッサ制御とプレミアム過熱保護装置。

3.正確なPID温度コントローラー。

4.適切に設計されたソリッドステートリレー(SSR)と保護デバイス。

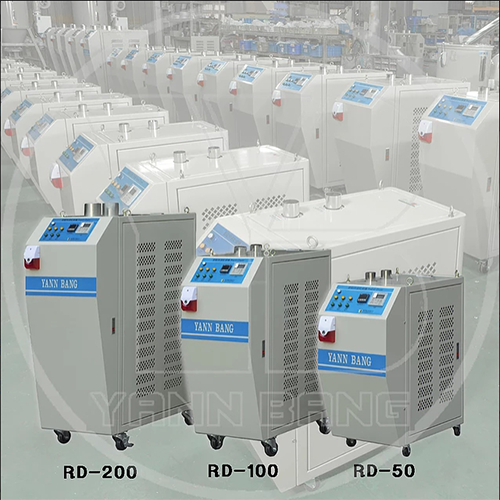

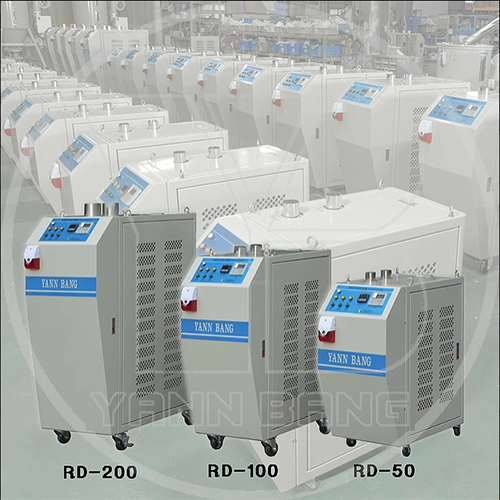

Rapid Dryer (RD)

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently.

1. Wide application. Suit to numerous material such as PC, PMMA, PA46, PPS, NYLON and some PET/PETG.

2. Save time and energy. Patented technology significantly shortens the drying time. Normally NYLON takes four hours to dry. Work with Yann Bang’s rapid dryer (RD), it only takes two hours to dry completely and ready to use. RD can decrease 50% of drying hours and save 50% of energy for you.

3. Upgrade energy save. Combine with Yann Bang’s Energy-efficient Hopper dryer can save more energy obviously.

4. Increase yield rate of output. Moisture content can be reduced to 0.02% (depend on the initial moisture content of resin), improve the drying quality of resin, and lower defective products.

5. Easy maintenance. Install with plug-in air filter and dust collector (oil collector) that you can unload easily to clean and replace parts.

マスターバッチは、マシンホッパーでバージンレジンと自動的に混合されます。 樹脂を事前に着色したり、事前に混合したりする必要はもうありません。 人件費、樹脂費、在庫費を節約し、作業環境を清潔に保ちます。

ユニットは、マスターバッチ、添加剤、流動性粉末、再研磨されたバージン樹脂を混合して投与し、一貫した正確な混合を保証します。これにより、製品の品質が向上し、不良品が少なくなります。