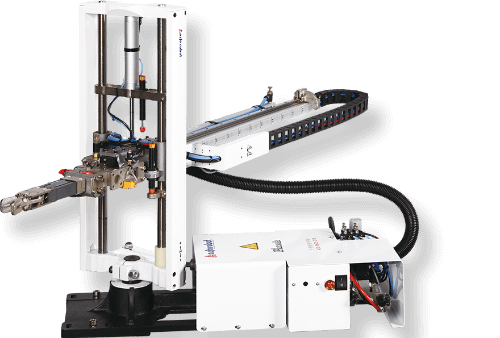

分類: 射出ロボット

国: 中国

電話番号: 86-769-83180326 (237)

ファックス: 86-769-83180329

連絡先: Kathy Zeng

PV□□□□RT

Model: 450/650/850

R: Rotate 60-90°, no mark does not rotate

T: The clamp rotates 180° without a mark and does not rotate

| Standard | ||

| 1 | Language switching | Support Chinese or English or Chinese and Japanese switching |

| 2 | Teaching function | Programs can be programmed as needed to achieve special actions |

| 3 | Spin out standby | Use when the top of the mold interferes with the robot or fixture |

| 4 | Fixture detection | High performance magnetic switch to confirm the presence or absence of gripping the material or product |

| 5 | Fixed mold removal | When the product is in the form of a template, it can be set to the fixed mold side to take the product. |

| 6 | Built-in material | After the nozzle is clamped in the mold or the product is sucked, the material or product can be released in the mold. |

| 7 | Conveyor belt interface | Control conveyor belt operation, stop |

| 8 | Memorable program | Can save 24 sets of mold data |

| 9 | Screen saver settings | The man-machine does not use automatically for more than a certain period of time, and the time can be set. |

| 10 | Spin-in and double-head valve control | When the power is off, the screw-out mechanism remains in the original state and does not interfere with the injection molding machine. |

| 11 | USB interface | Use U disk to upload, download mold data, update program |

| Optional | ||

| 1 | Suction loop | Scalable 1 set suction circuit |

| 2 | Spraying agent | When the product is not released, the interval can be set and the spray time can be set. |

| 3 | Medium plate inspection | Confirm the position of the middle plate during the three-plate mode to avoid the jib collision |

| 4 | European standard connector | Configurable EUROMAP12 or EUROMAP67 standard connectors for connection to injection molding machines |

| model | PV450/R/T/RT | PV650/R/T/RT | PV850/R/T/RT |

| Applicable molding machine (ton) | 30-60 | 50-160 | 160-300 |

| Side entry stroke (mm) | 450 | 650 | 850 |

| Up and down stroke (mm) | 75 | 75 | 200 |

| Swing angle (degrees) | Standard no rotation optional R: 60-90° | Standard no rotation optional R: 60-90° | Standard no rotation optional R: 60-90° |

| Fixture rotation angle (degrees) | Standard no rotation optional T: Rotate 180° | Standard no rotation optional T: Rotate 180° | Standard no rotation optional T: Rotate 180° |

| Maximum load (Kg) | 1 | 1 | 1 |

| Take time (sec) | 1.3 | 1.7 | 1.9 |

| Full lap time (sec) | 4 | 4.5 | 5.8 |

| Air consumption (NI/cycle) | 11 | 14 | 14 |

| Net weight (Kg) | 22 | 26 | 50 |

PV Series General Specifications

| power supply Power Source |

Power supply capacity (KVA) Power Capacity |

working pressure Working Pressure |

Maximum allowable air pressure Max.Allowed Pressure |

Drive mode Drive System |

| 1ΦAC 220V±20V 50/60HZ |

0.2 | 5kg/cm2 0.49Mpa |

8Kgf/cm2 0.8Mpa |

Pneumatic Cylinder |

- Program settings: 8 sets of built-in fixed mode, 4 kinds of teaching modes, to meet various production needs. For the statistics and management of production information, use charts to show convenient observations.

- Alternate output: can be connected to automation equipment such as conveyor belts, spray-off agents or air pressure shears.

- Storage capacity: 24 sets of mold data can be saved, including loading, editing, saving and other functions.

- System record: operation history, alarm history, easy to repair and find problems.

- IO display function: The top of the screen always displays the status of key IOs, such as safety door, mold opening, permission to close, permission to enter, product inspection, and easy maintenance judgment.

- Man-machine: 3.5-inch color LCD, dedicated manual button. The color is pleasing to the eye, the appearance is beautiful, the ergonomics is simple, the operation is simple and easy to learn, and the operation habits of different people are satisfied to the greatest extent.