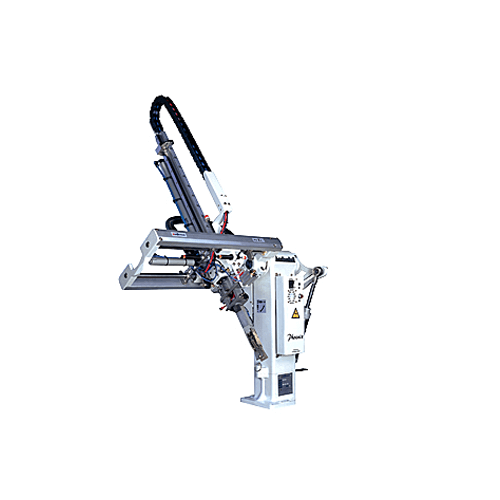

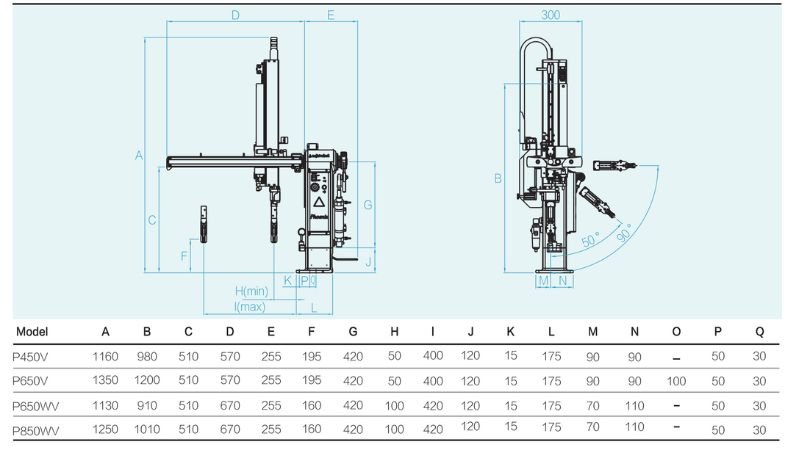

Arm Robots for injection molding machine

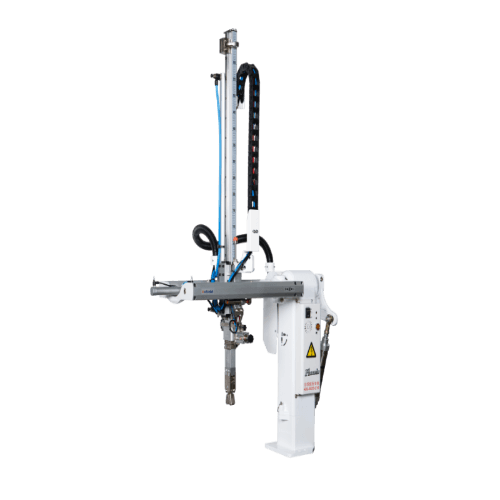

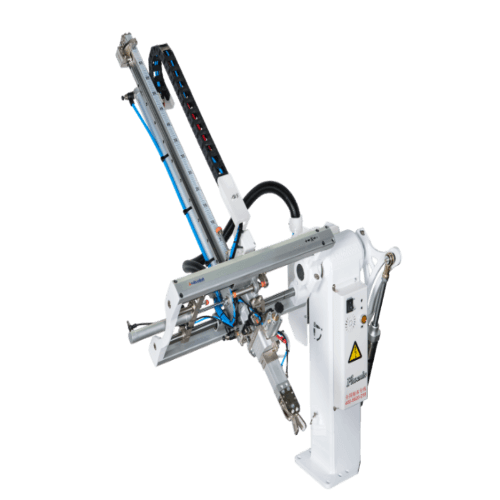

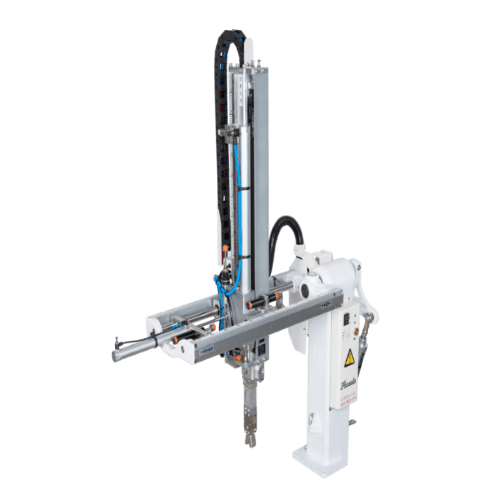

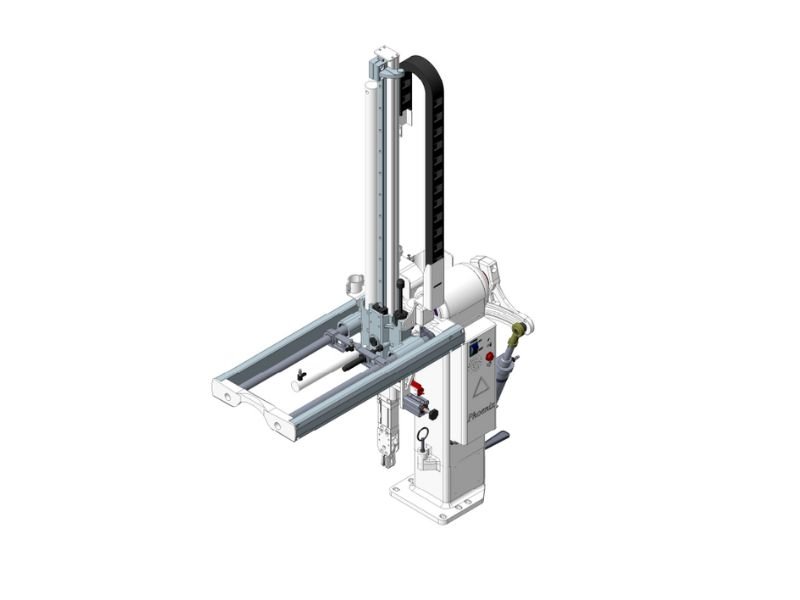

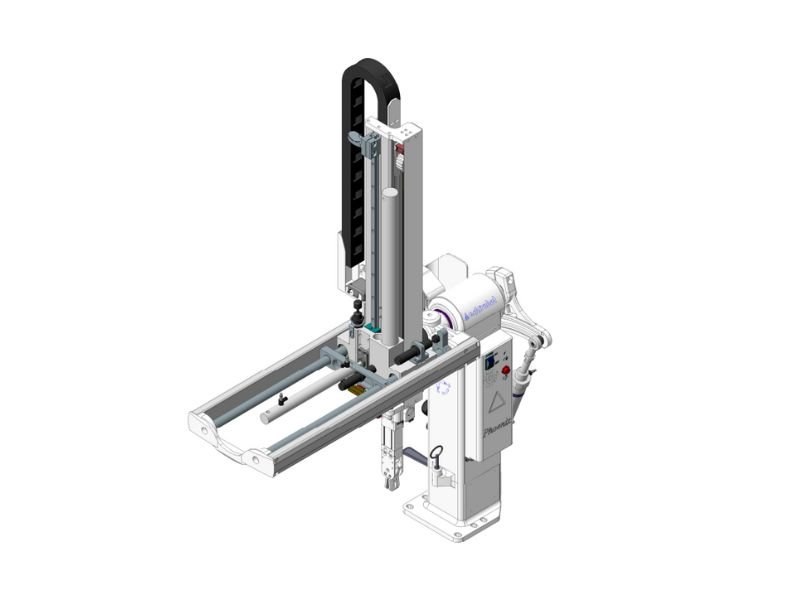

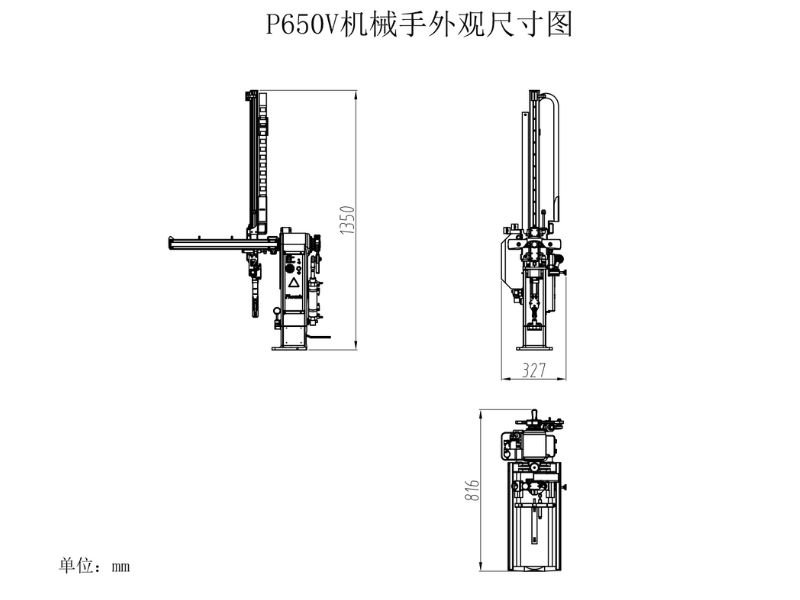

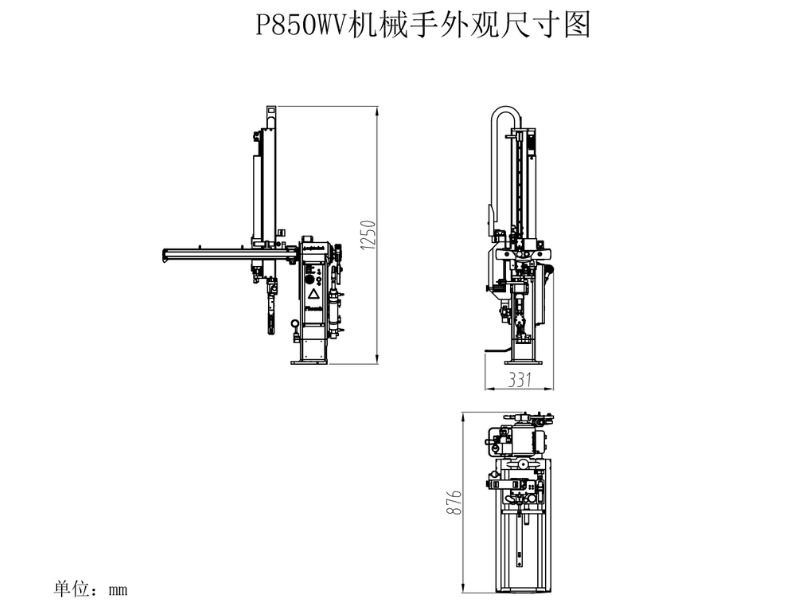

Fast speed, high efficiency, low noise, long life, economical molding industry, the most economical choice ,patent (patent number : ZL201310027721.7 /ZL201410353254.1/ZL201420407564.2) approvals, Phoenix series, 30-280 tons of various horizontal injection molding machines, used to remove finished products and sprue. We have model 450/650/850 , the vertical arm is single stage for P450V and P650V, P850WV is telescopic stage which are dedicated to two-plate molds; the single function is used for the sprue picking, and the full function with vacuum function can be used to pick up the sprue and take out the product simultaneously.

P□□□□WV

Model: 450/650/850

W: Telescopic stage

V: Vacuum function including vacuum generator and standard suction cup fixture. The air consumption of this model already includes suction function.

Main Specification

Phoenix swing arm robot is suitable for 30-300 tons of various horizontal injection molding machines, used to remove finished products and sprue.the single function is used for the sprue picking, and the full function with vacuum function can be used to pick up the sprue and take out the product simultaneously. The rotary assembly mechanism can rotate the product 90 degrees. The function of this robotic arm can increase productivity by 20%-30%, reduce product defect rate, ensure operator safety, reduce labor cost and control production precisely and reduce waste. The rotary assembly mechanism can rotate the product 90 degrees. The function of this robotic arm can increase productivity, reduce product defect rate, ensure operator safety, reduce labor cost and control production precisely and reduce waste.

Phoenix Series General Specifications

| power supply Power Source |

Power supply capacity (KVA) Power Capacity |

working pressure Working Pressure |

Maximum allowable air pressure Max.Allowed Pressure |

Drive mode Drive System |

| 1ΦAC 220V±20V 50/60HZ |

0.2 | 5kgf/cm2 0.49Mpa |

7Kgf/cm2 0.7Mpa |

Pneumatic Cylinder |

|

|

|

Left-right Rotation mechanism To change the placing sprue or product direction, the user only needs to adjust the screw without changing the air pipe and magnetic switch. |

Mold change adjusting structure While changing mold, user only needs to loosen the fixed handle and the robot can rotate 90 degree to increase the mold-changing efficiency. |

|

Rotation Wrist Structure With a rotation wrist structure, the gripper can rotate 90 degrees to place the product.

|

Telescopic stage arm U sing high rigidity linear slide rail and aluminum alloy structural beam, telescopic special designed belt speed mechanism, can greatly shorten the structural height of the vertical arm. In addition to increasing the speed and stability of the vertical a rm, but also can cooperate with the low height of the plant. |

|

|

| P650V | P850WV |